Products

MHM Automation is recognised for providing innovative and reliable systems and equipment that improve safety and optimise product quality. Our product range includes:

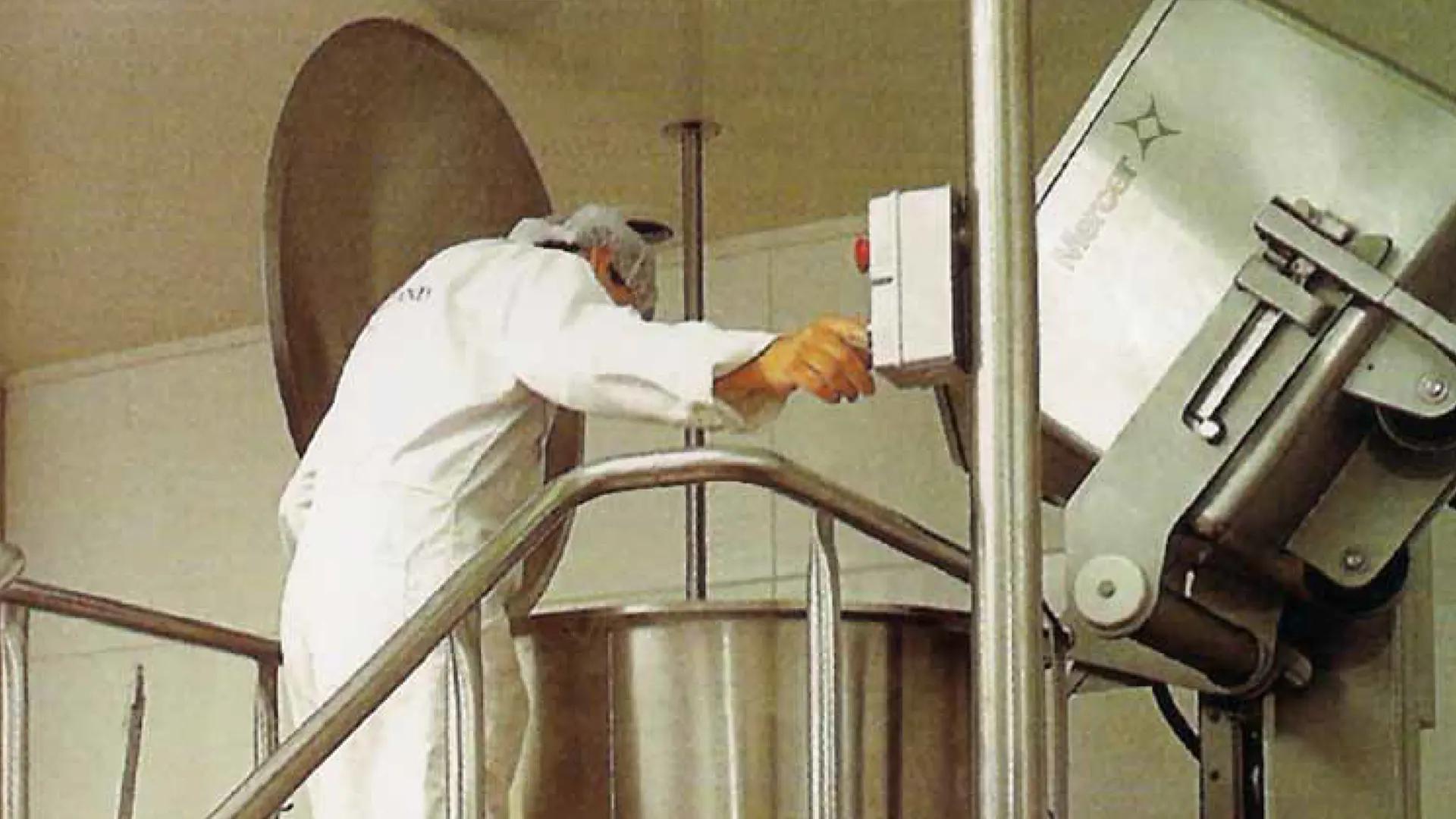

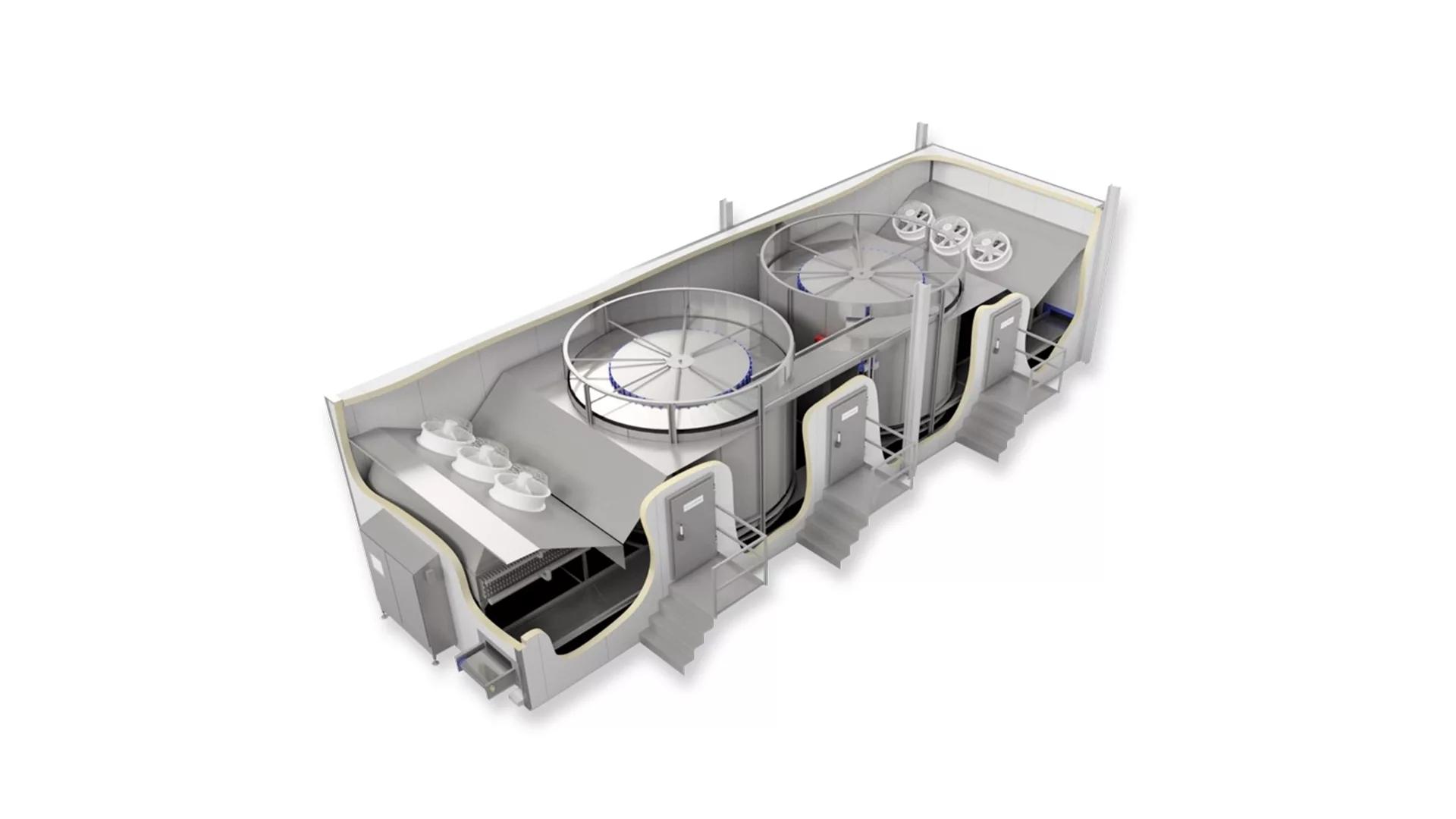

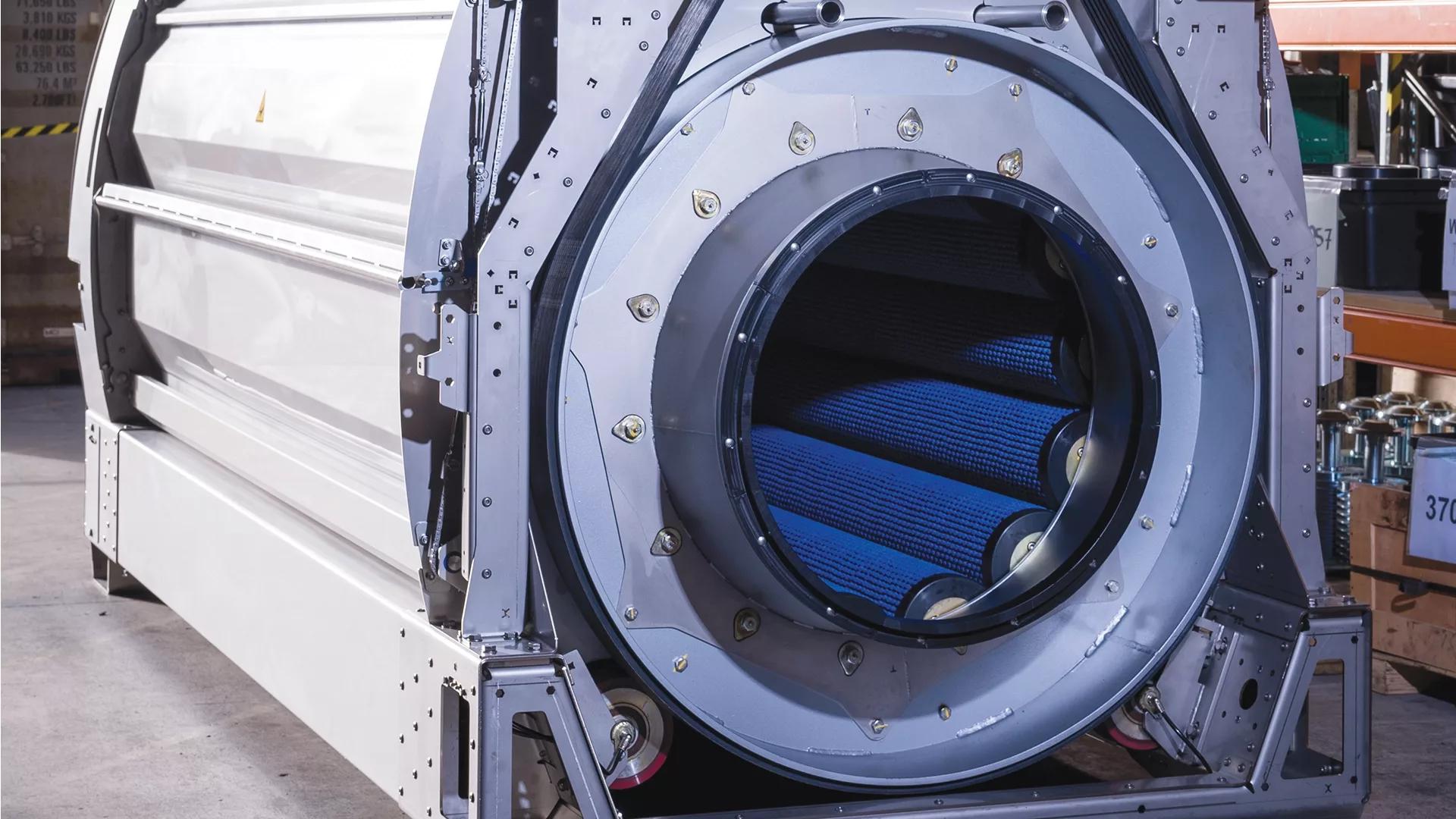

Chilling & Freezing

Fabrication

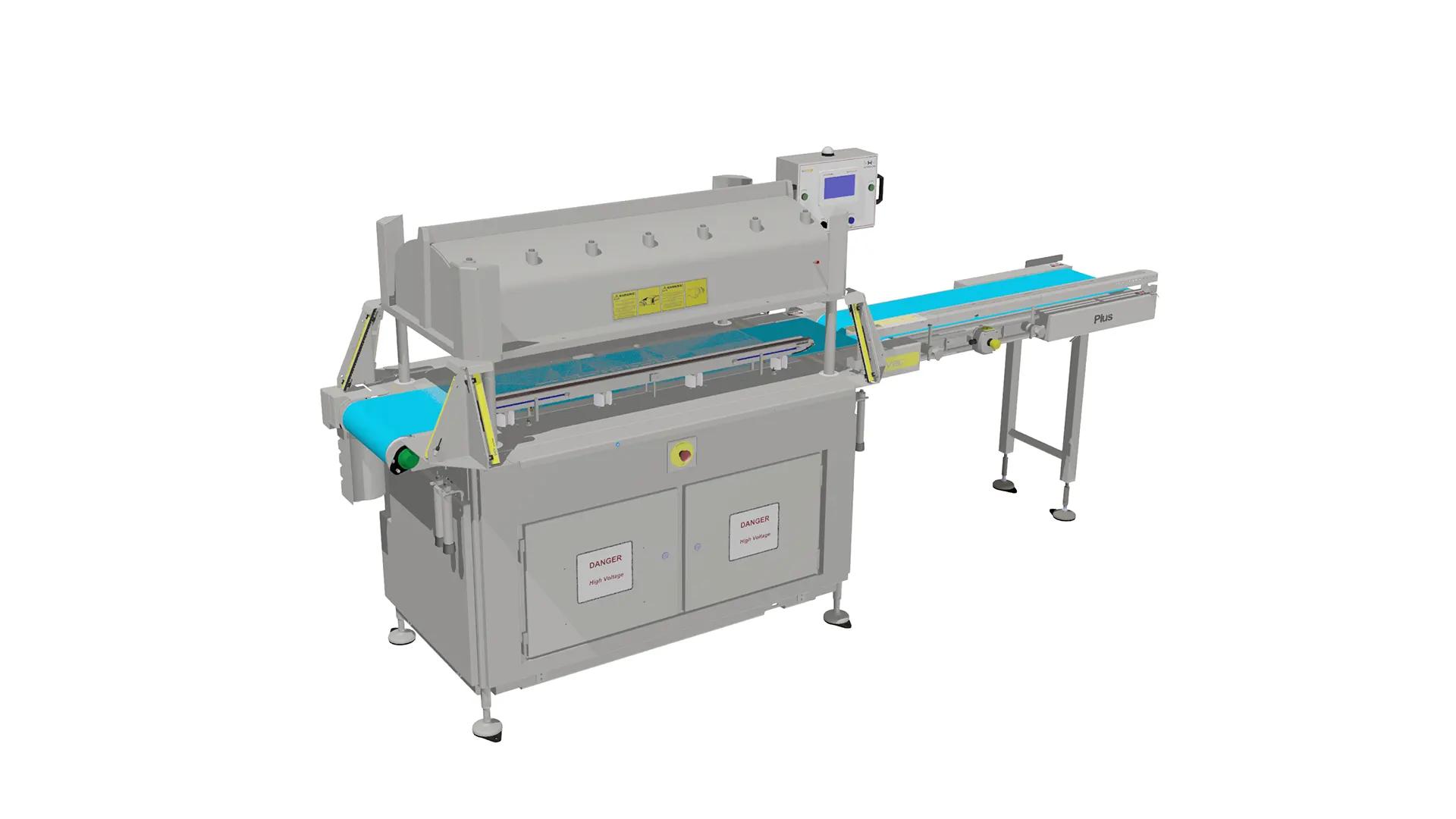

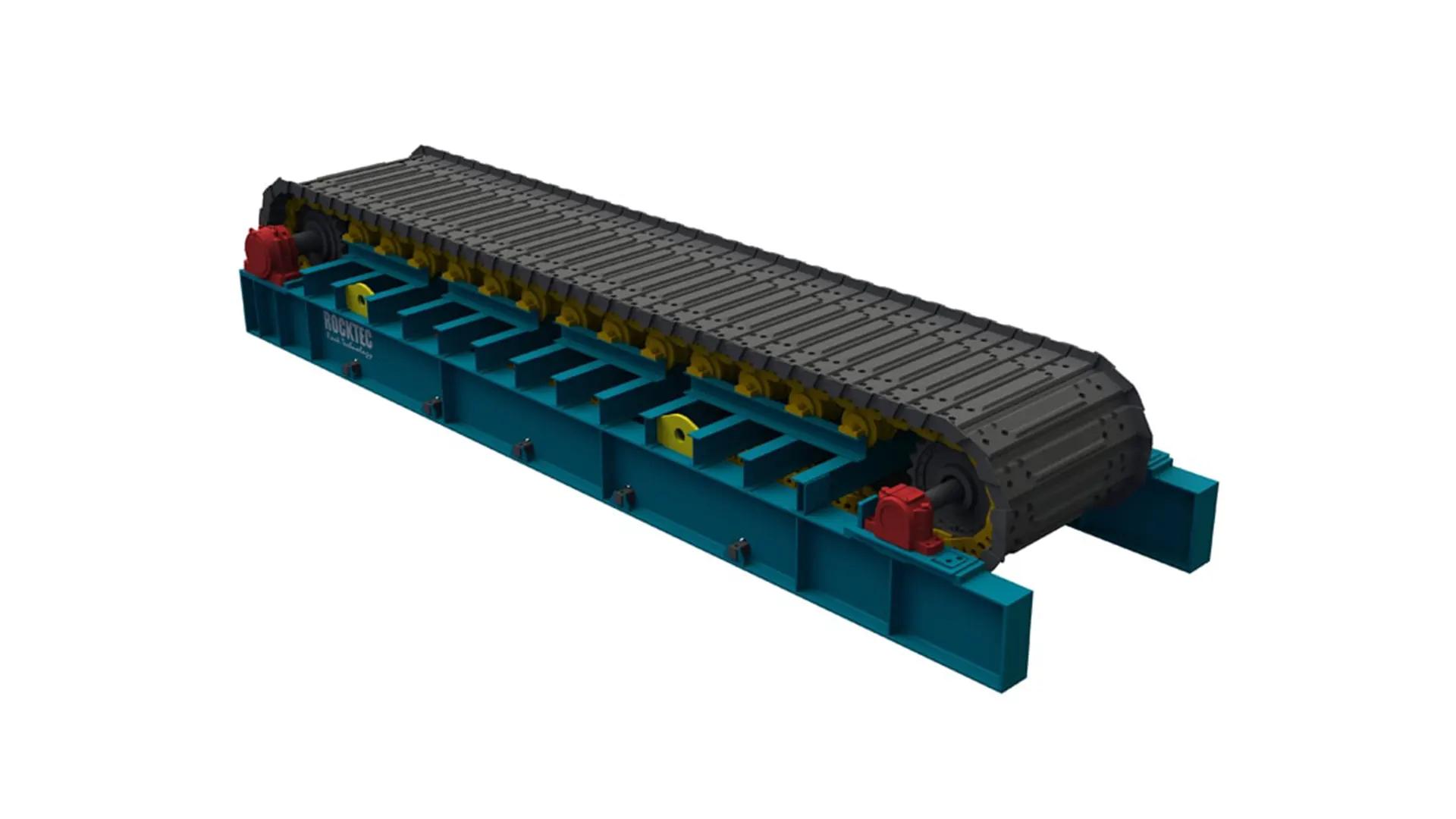

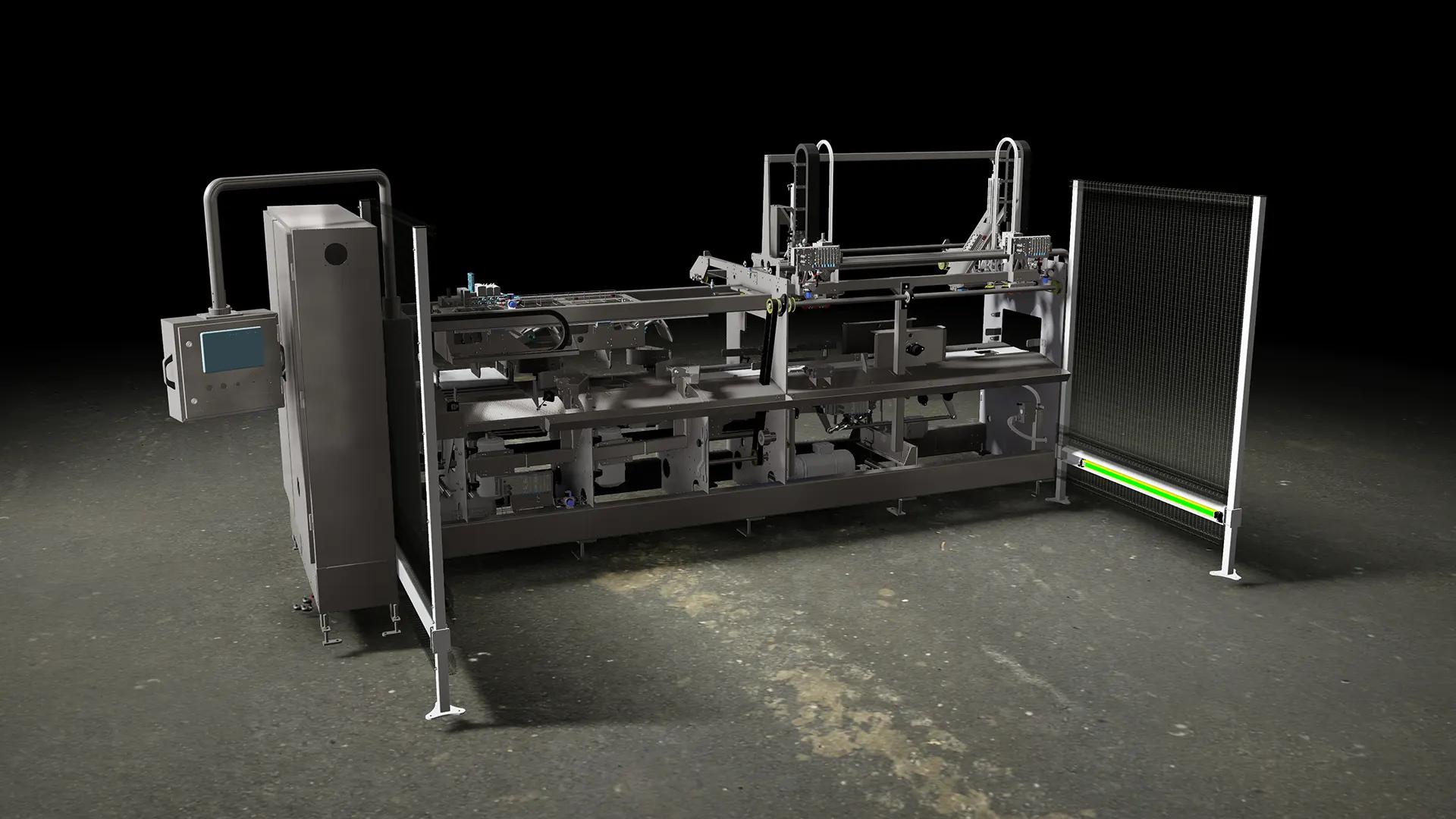

Materials Handling

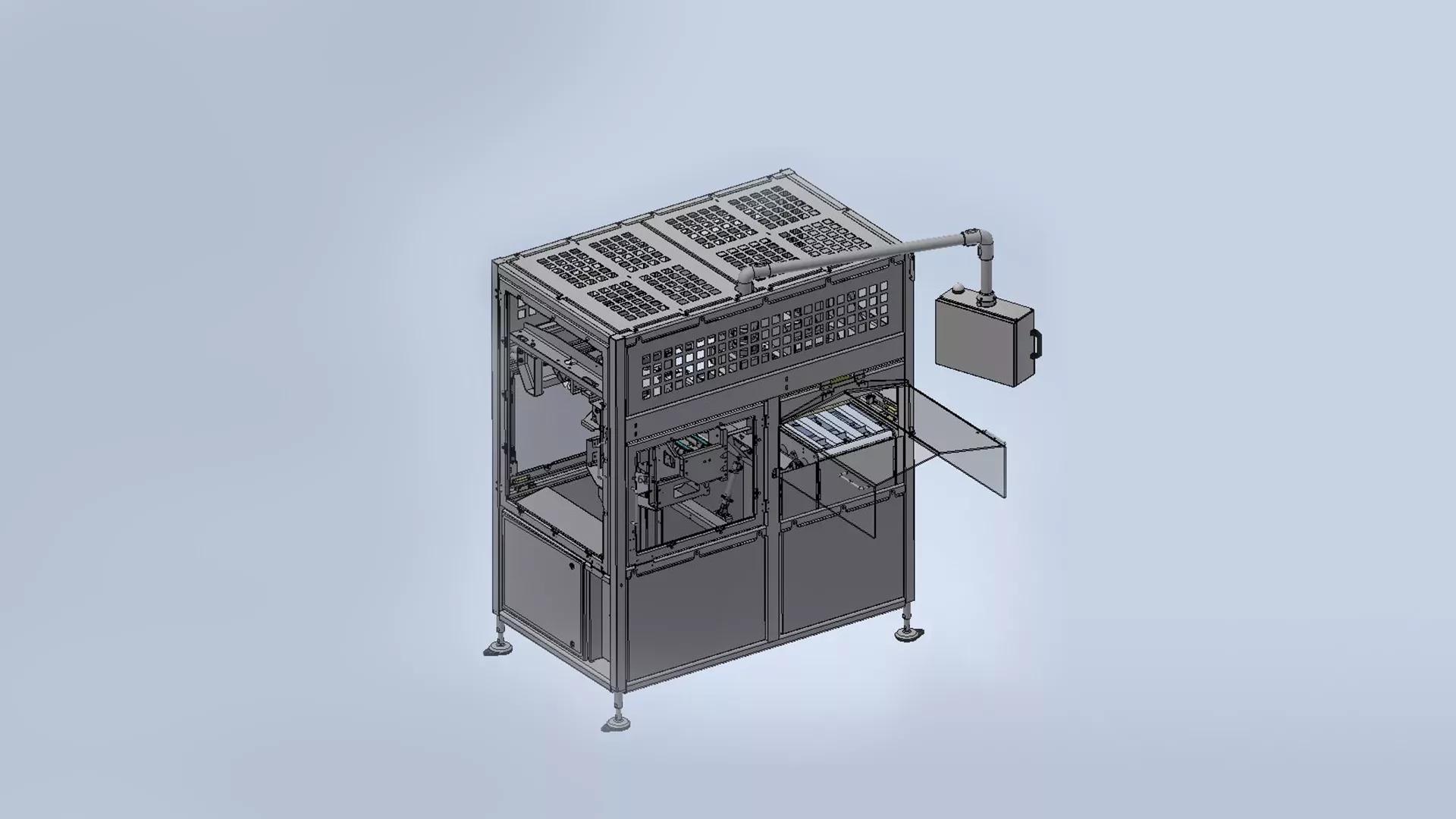

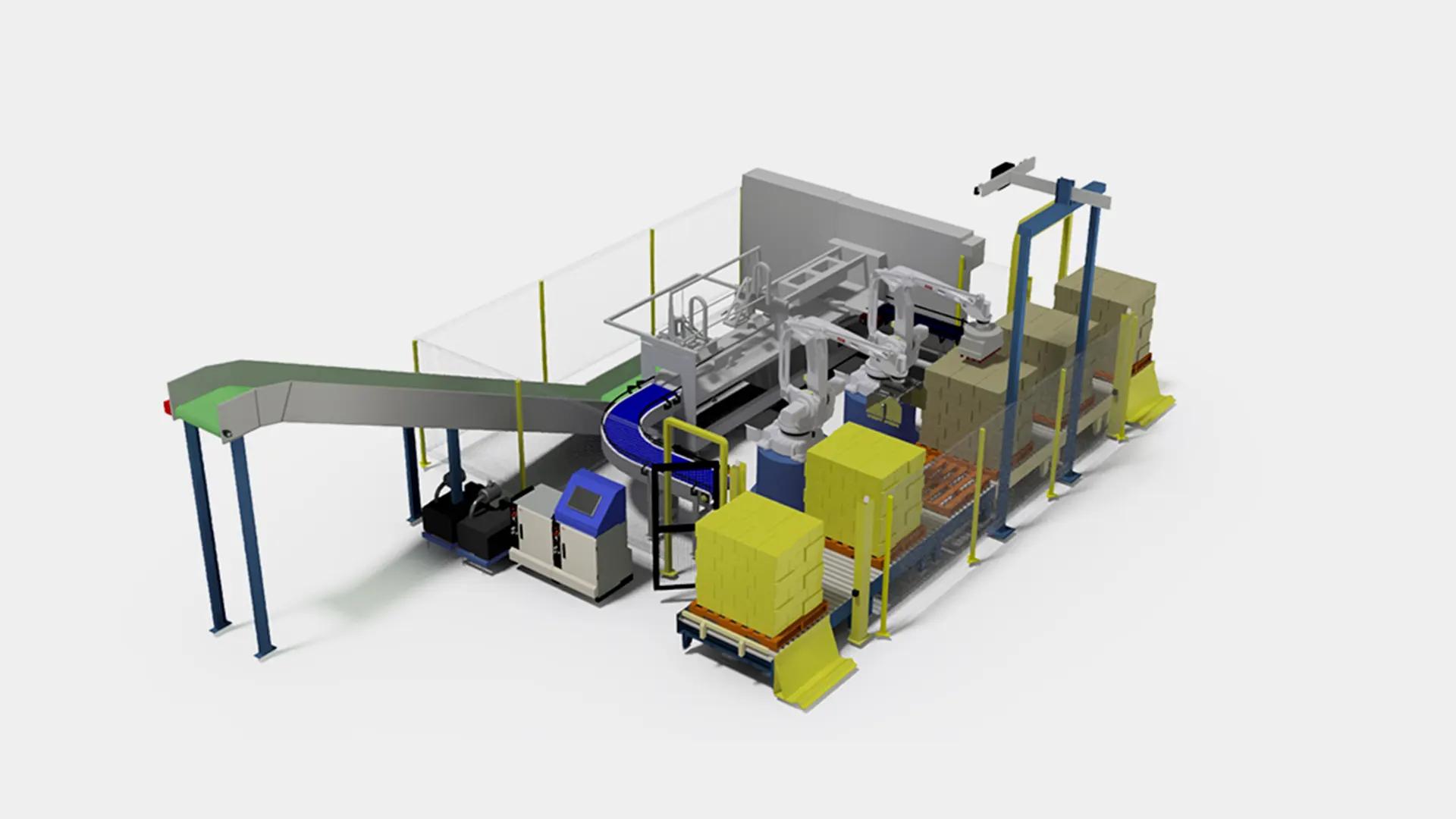

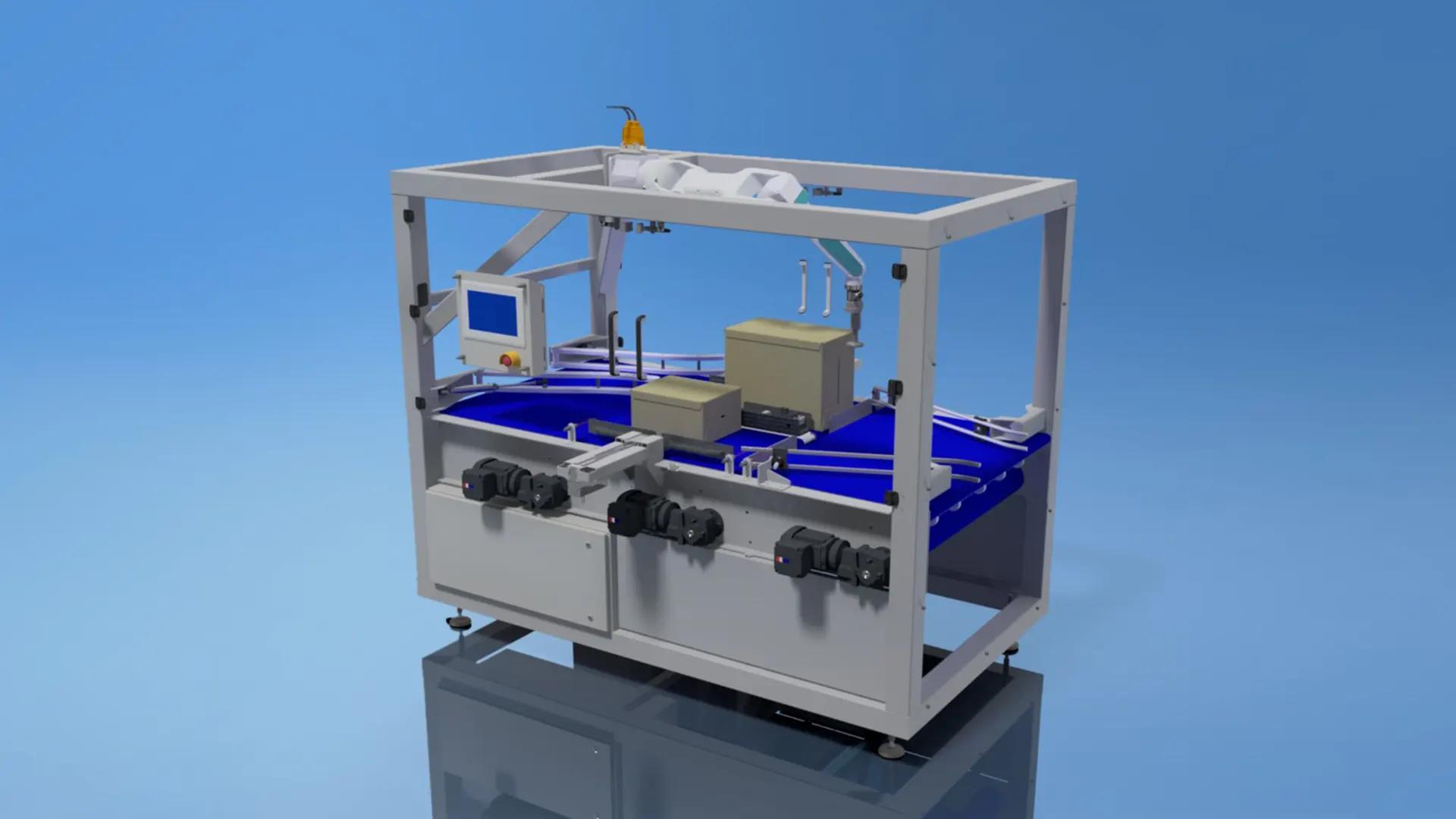

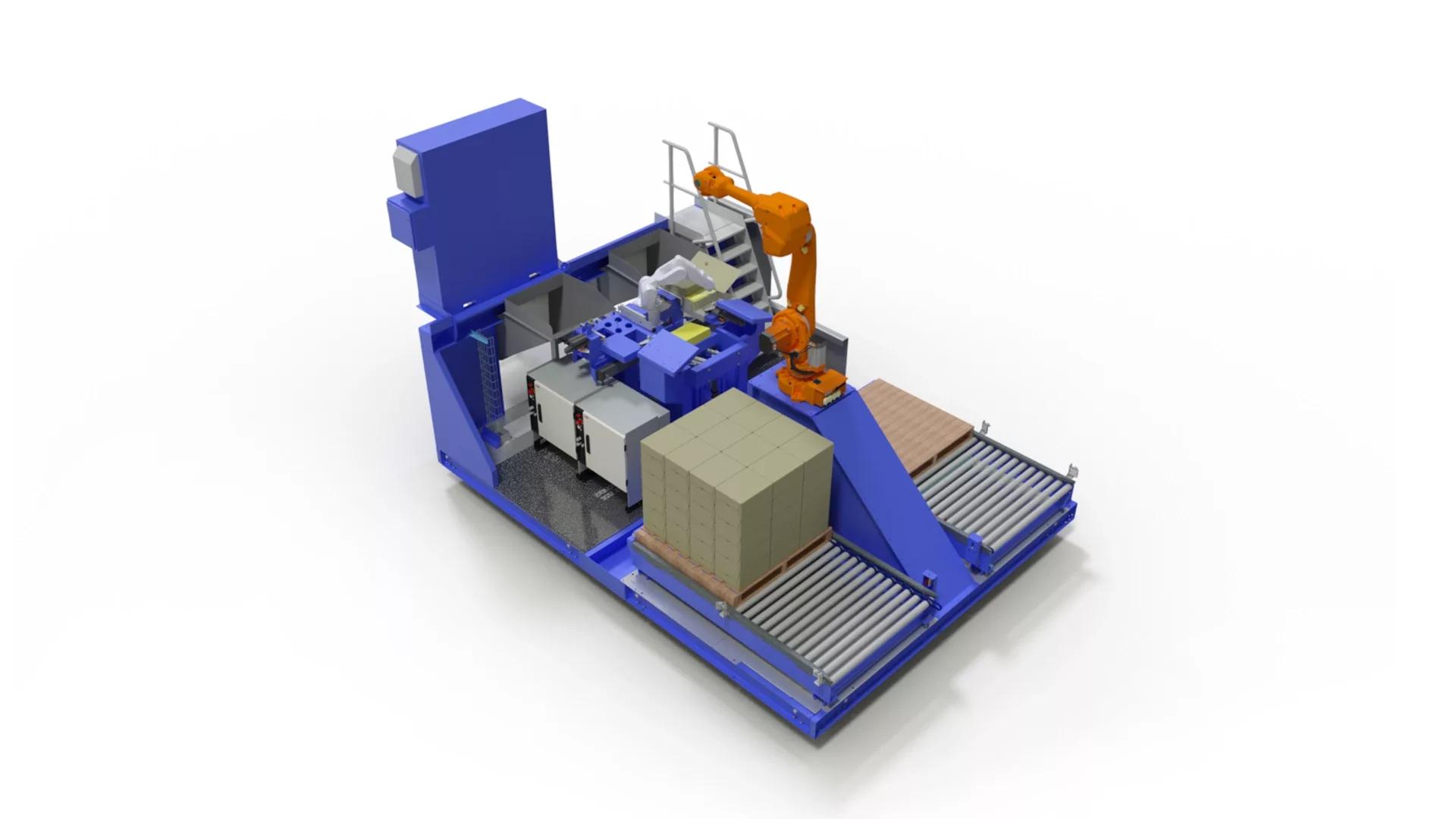

Packaging

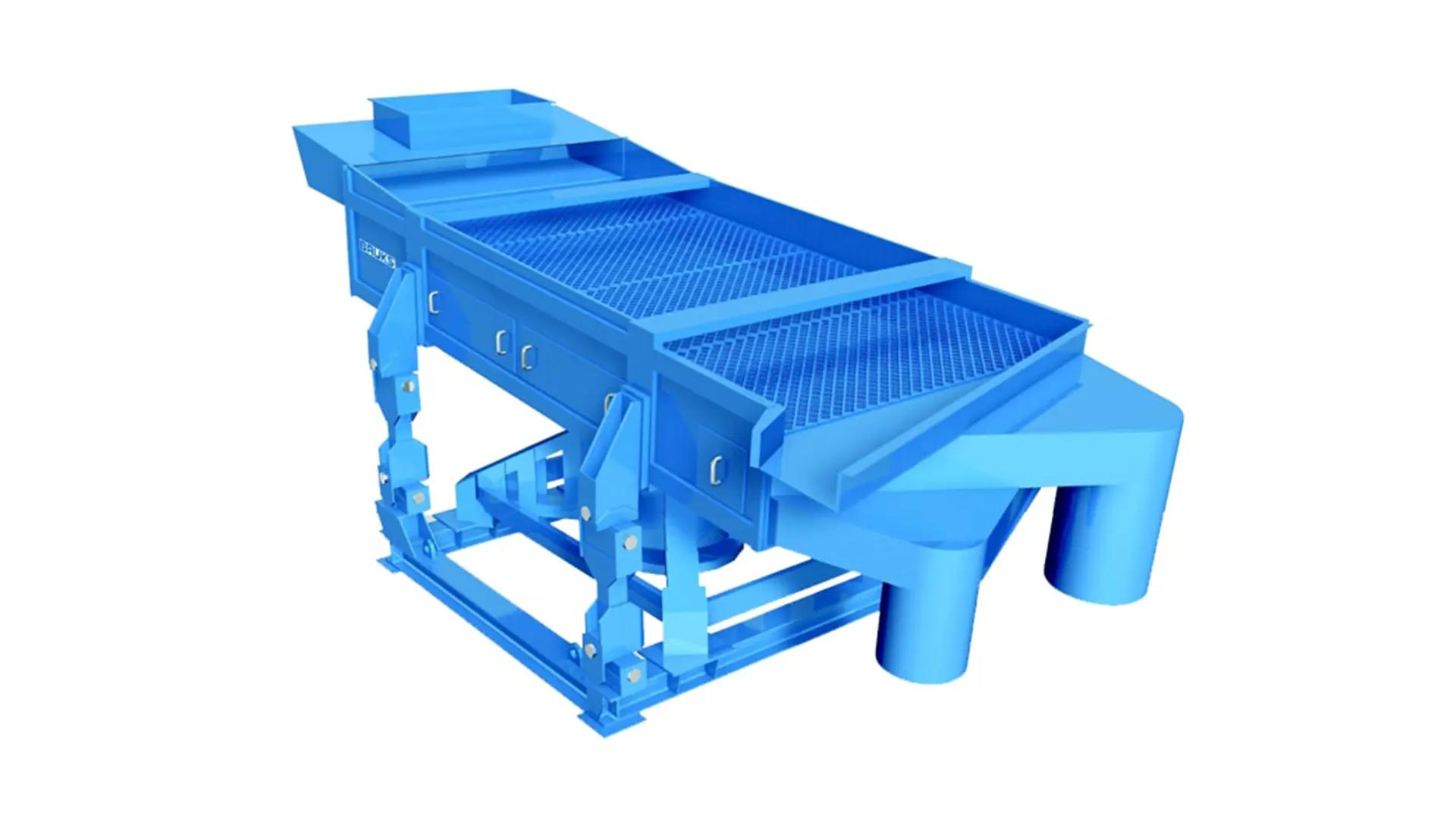

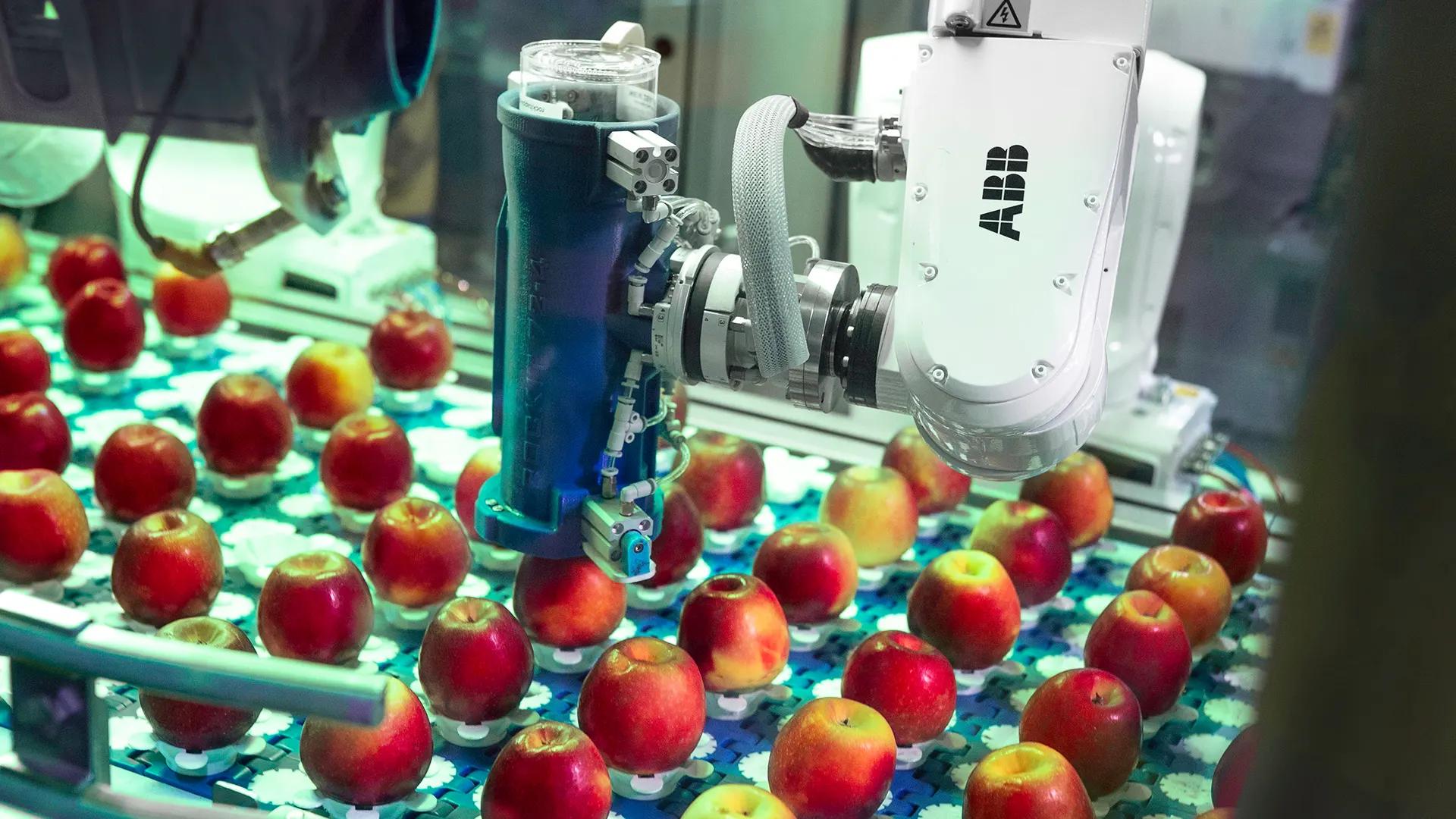

Post-Harvest

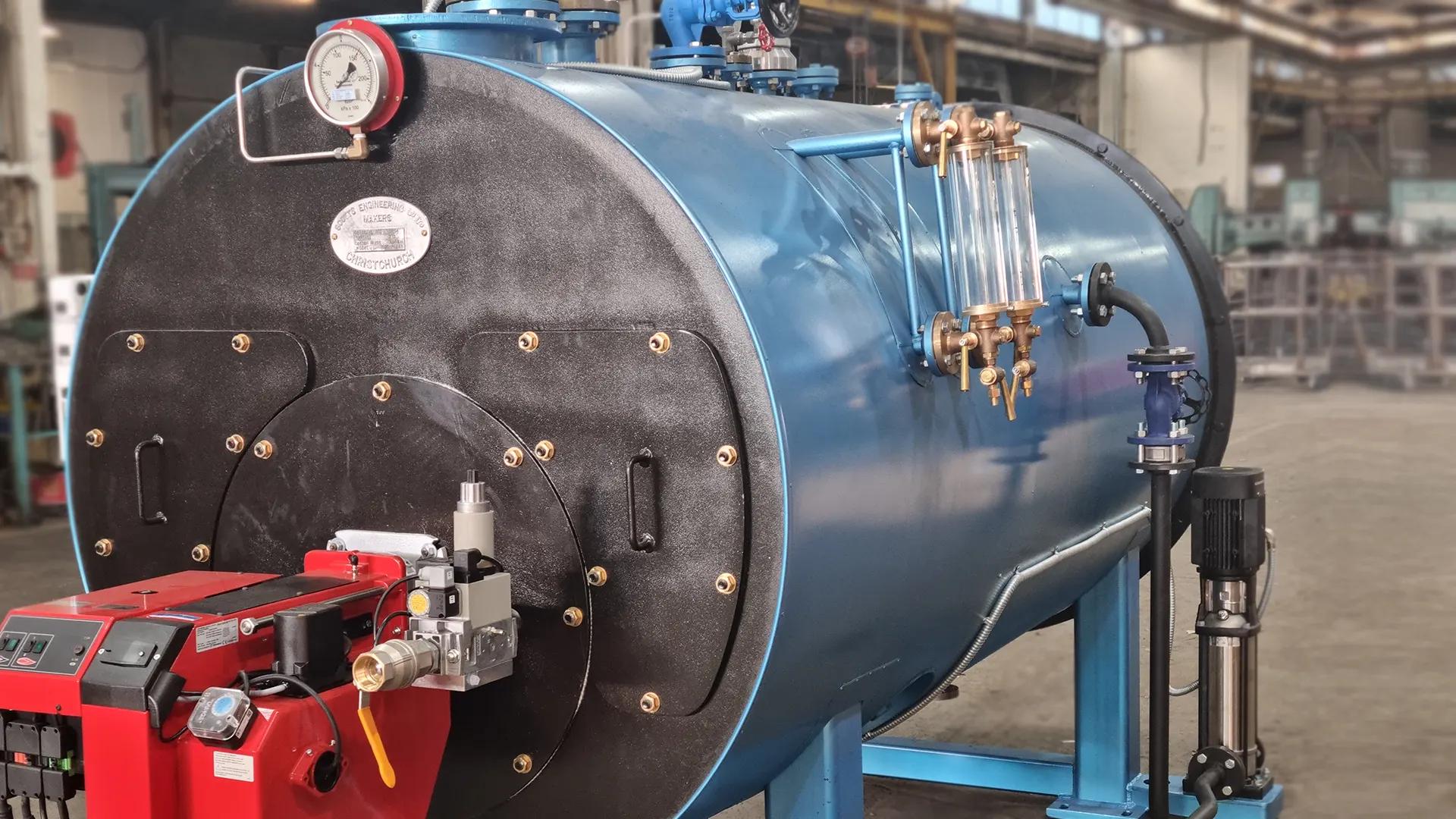

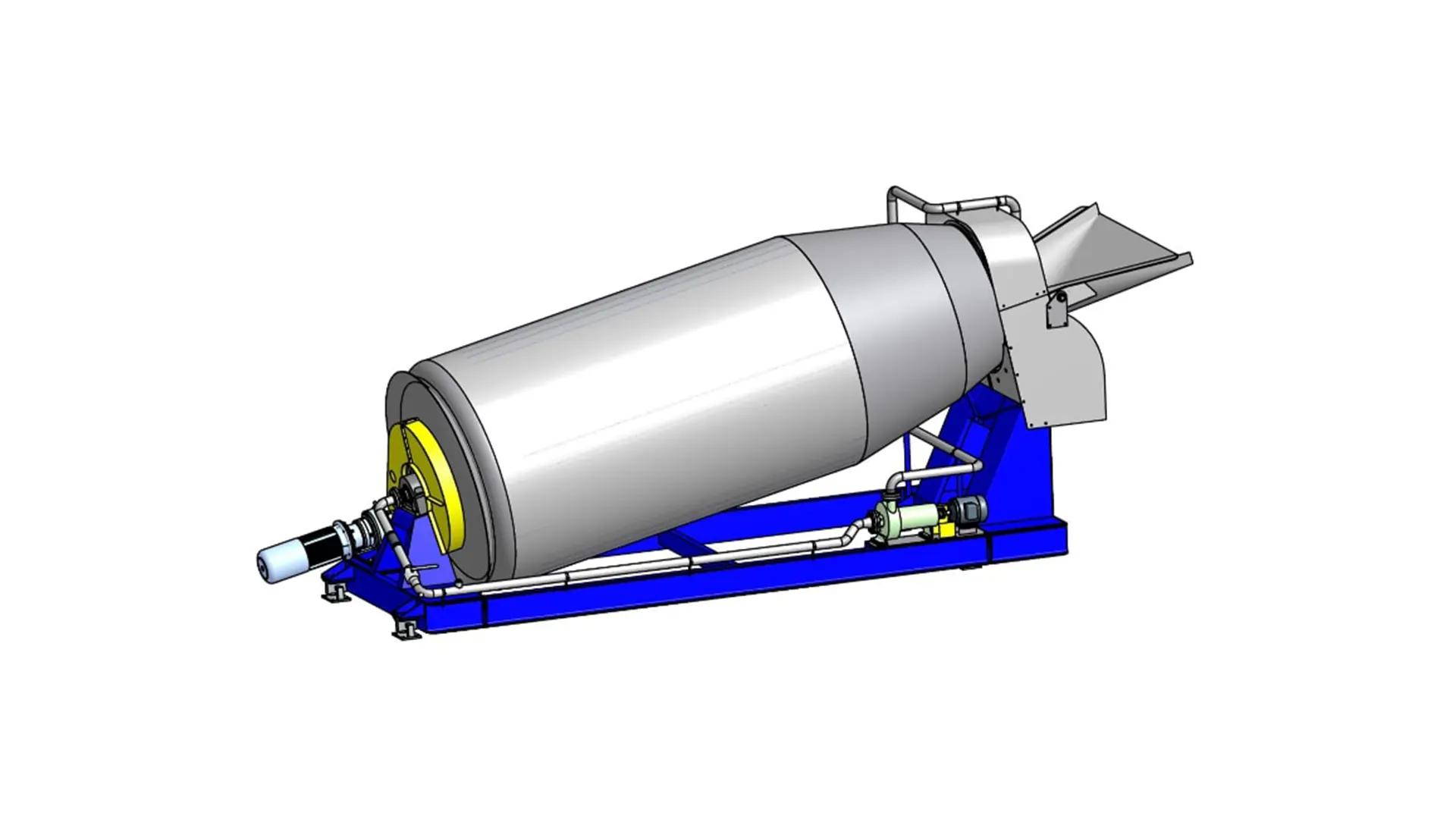

Pressure Vessels

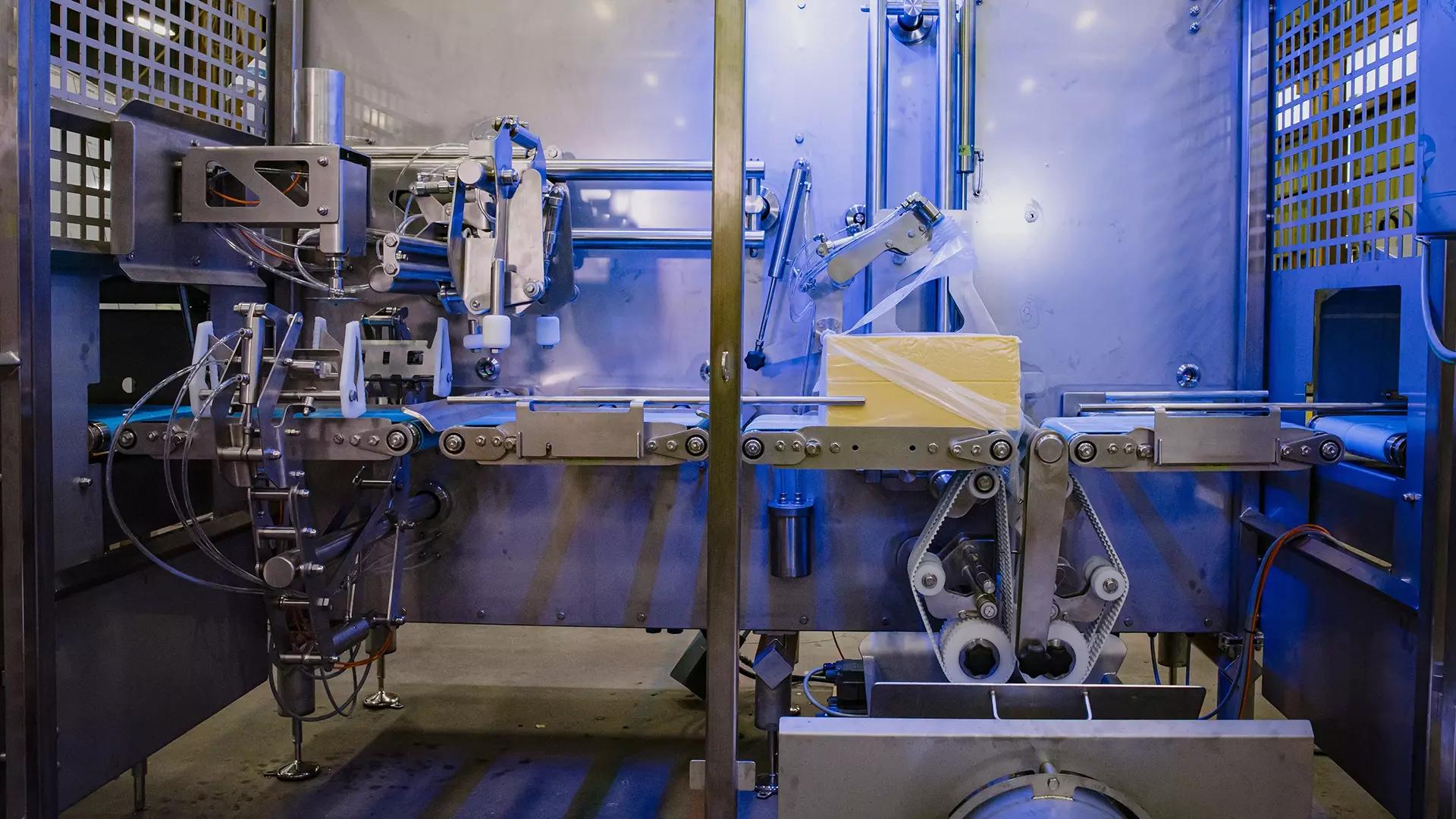

Reverse Packaging

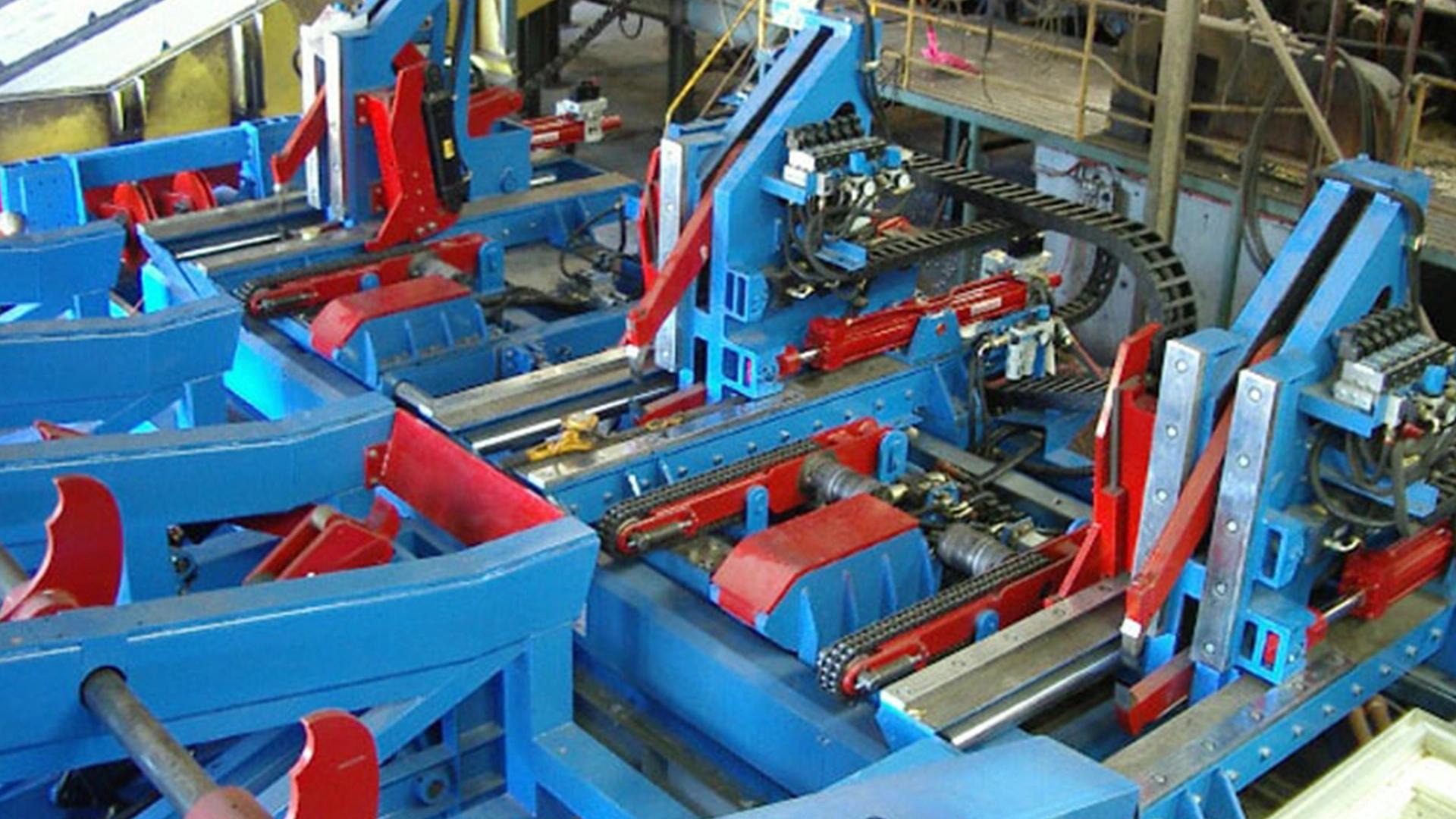

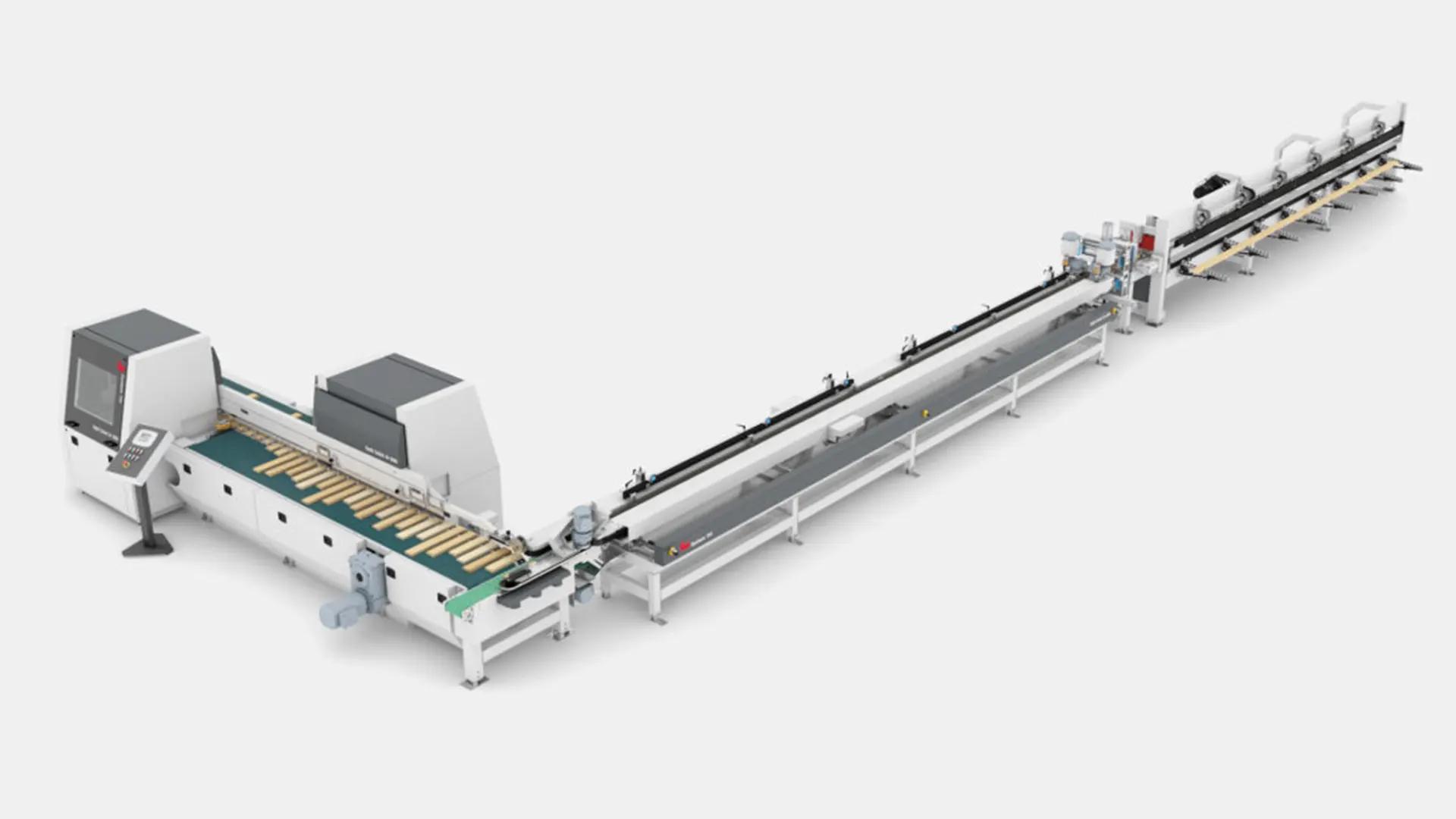

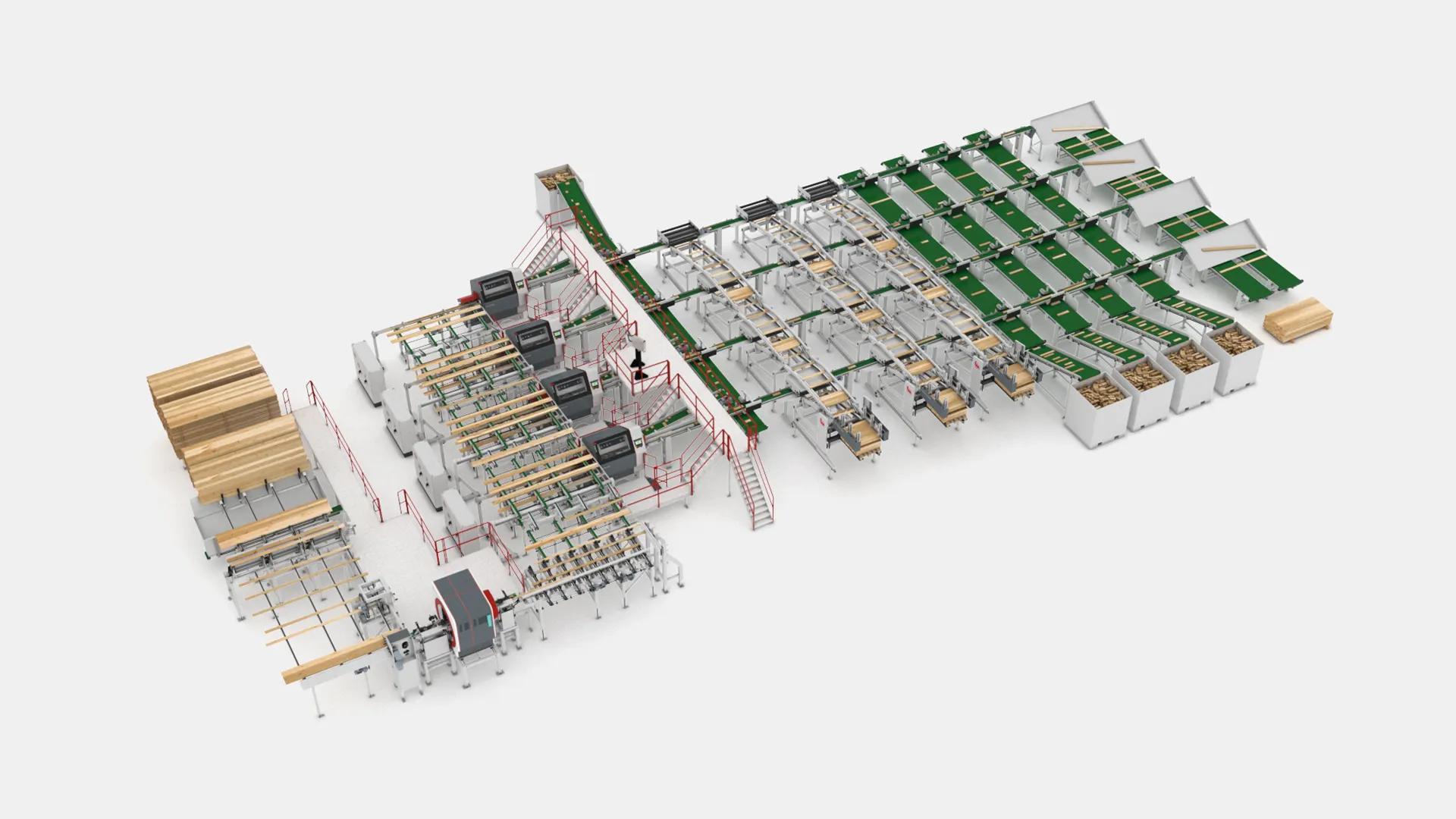

Timber & Sawmilling

Spare Parts & Service