Open and remove product from boxes of varying shapes and sizes the safe, hygienic and efficient way with the Universal De-boxer.

This machine has been developed to remove the need for operators to manually open boxes or cartons. It is particularly suitable for lines where bulk product is being prepared for further processing, such as beef trim that is to be processed into burger patties.

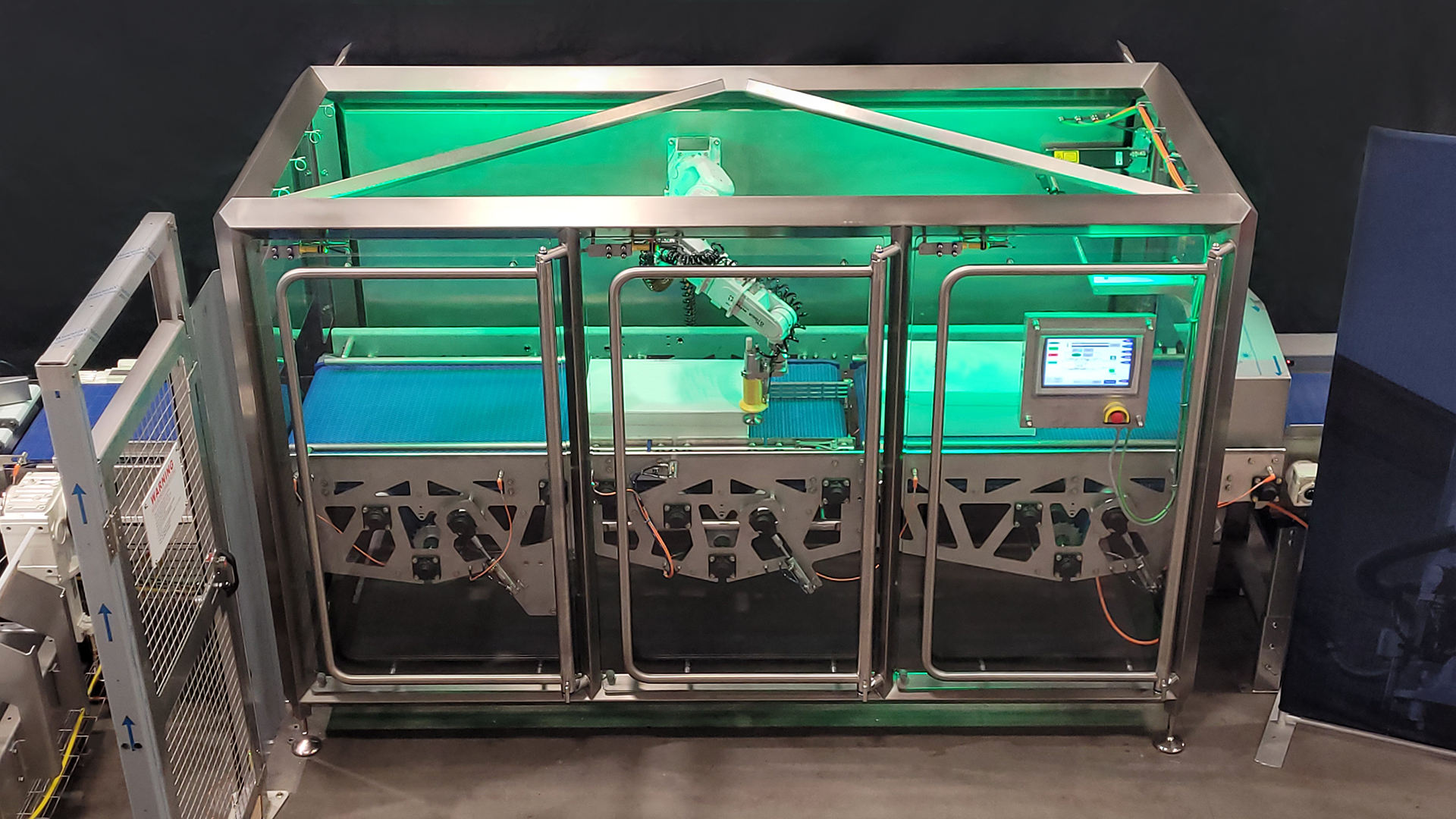

The first module is known as the Universal Box Cutter, or UBC, and cuts open the tops of sealed boxes.

The UBC uses vision technology to scan each box to determine its size and shape, and then deliver the optimal cut profile for each box, on the fly, without the need for operator intervention. It is capable of cutting box straps and bands, and adapts automatically to handle damaged boxes.

The second module lifts the cut top or lid off the box, inverts the box and then removes the bottom of the box to deliver the contents onto the conveyor line, ready for further processing. Waste cardboard is conveyed to a cardboard compactor or centralised location for recycling.

Our universal de-boxer solution can be provided with the first, second or both modules, depending on the requirements of the processing line. It is often delivered together with a de-palletising system, to provide a completely automated solution to the front-end of a secondary processing line.

Applications

- Operations where bulk product needs to be removed from boxes to prepare it for further processing.

- Lines handling multiple box sizes and/or box formats (such as taped, glued and shoebox style boxes)

Key Benefits

- Operator input not required for box size and shape changes

- Reduces labour requirements – allows staff to be redeployed to higher value work

- Eliminates manual handling, knives and the associated risk of injury

- Removes risk of product contamination by operators

- Sanitary design with full wash down compatibility

Previously known as the H&C Universal Box Cutter, this system was originally developed by Haden & Custance (H&C), which is now part of MHM Automation.