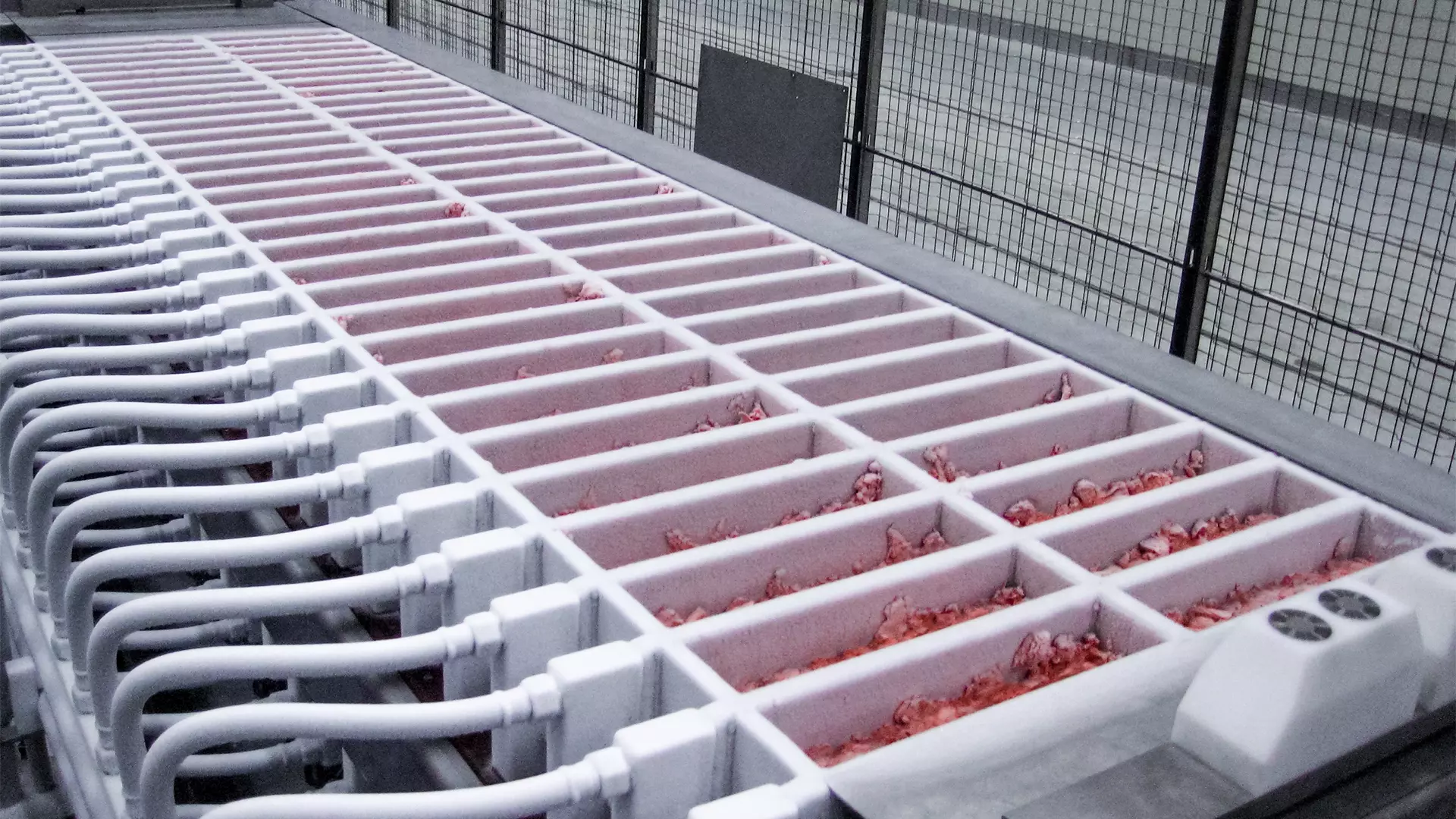

Vertical plate freezers are ideal for freezing large volumes of food and liquids very quickly to sustain the food quality and ensure food safety.

Double contact freezing of naked blocks typically results in a freezing cycle of 3-4 hours.

In Australia and New Zealand, vertical plate freezers are primarily used in the meat and pet food industries for freezing offal, blood, MDM and inedible by-products destined for pet food.

Vertical plate freezers are also favoured by offshore fishing vessels and onshore seafood processing operators, where they provide fast, gentle freezing of bulk seafood to prepare it for export.

MHM Automation is the exclusive Oceania distributor and service partner for DSI Dantech vertical plate freezers.

DSI Dantech vertical plate freezers are manufactured in Denmark with Danish precision. They are renowned for high reliability and long service life, even in demanding production environments.

Applications

- Offal, blood and MDM from red and white meat, destined for pet food

- Onshore or offshore freezing of seafood products

Benefits

- Very fast freeze – typical cycle time 3-4 hours

- Preserves taste, texture and nutritional value of food

- Energy efficient – plate freezing is up to 30% more energy efficient than other freezing technologies

- Affordable, with a strong ROI

- Low maintenance costs

- Hygienic design, easy to clean

Features

- DSI vertical plate freezers use a single pass of refrigerant in the plates to provide the best heat transfer possible – especially compared to other plate freezers on the market that use double pass – and results in a faster freezing time.

- Manual and automatic loading/unloading options are available.

- V16 series optimises space utilisation and avoids manual handling by automatically unloading directly onto a conveyor, which is placed beneath the freezer unit.

- Each freezer is custom designed – capacity, block size and footprint can be tailored to suit your operation.

- Compatible with a range of refrigerants, including ammonia (NH3), CO2, Freon, R717 and brine.

- Proven technology, with more than 10,000 installations worldwide.