Need to scan naked cheese blocks for mould and foreign material contamination in a high hygiene area?

The Defect and Foreign Object Detection (DFOD) unit provides the critical control point for cheese blocks entering a processing plant, prior to further processing.

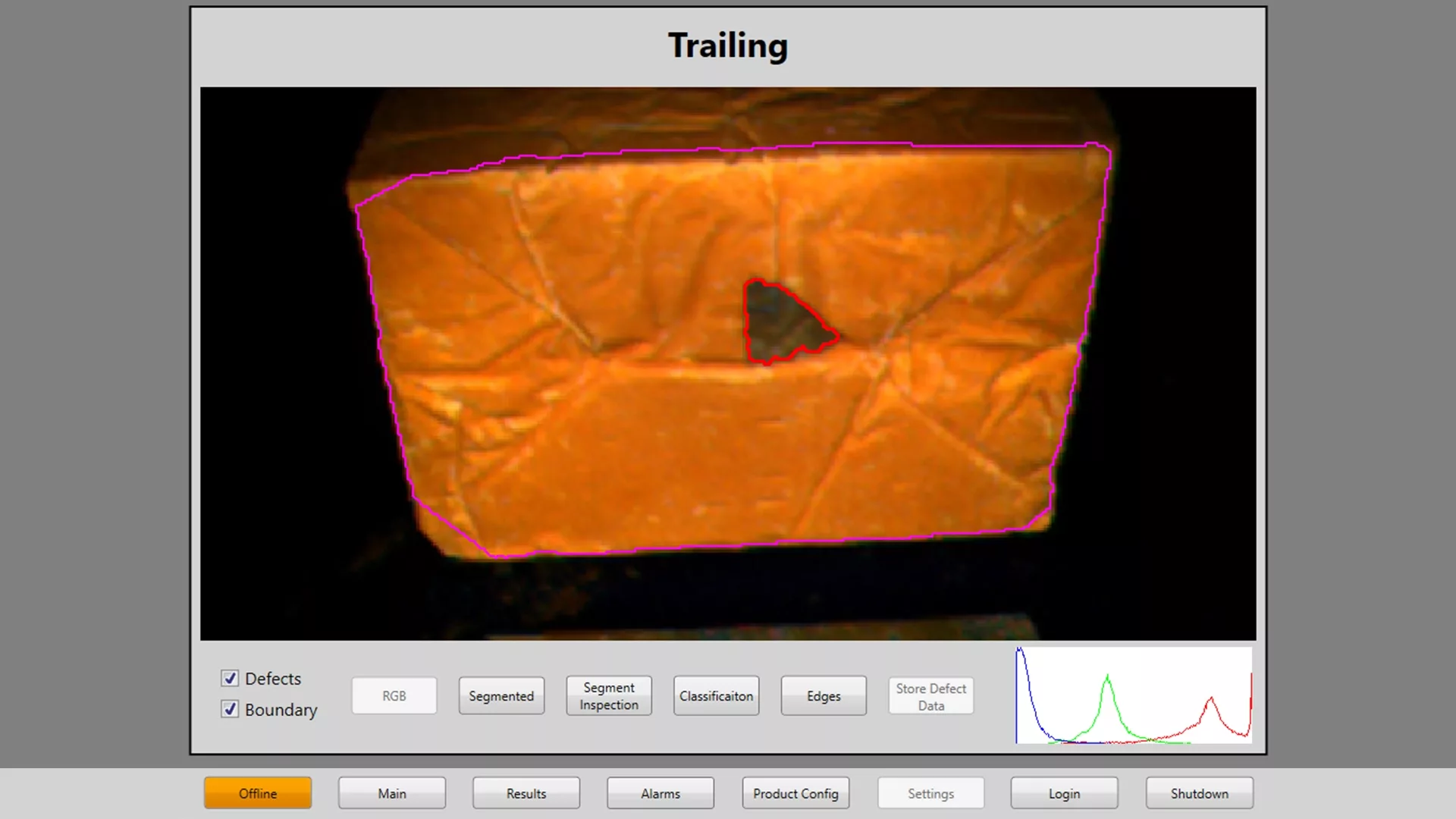

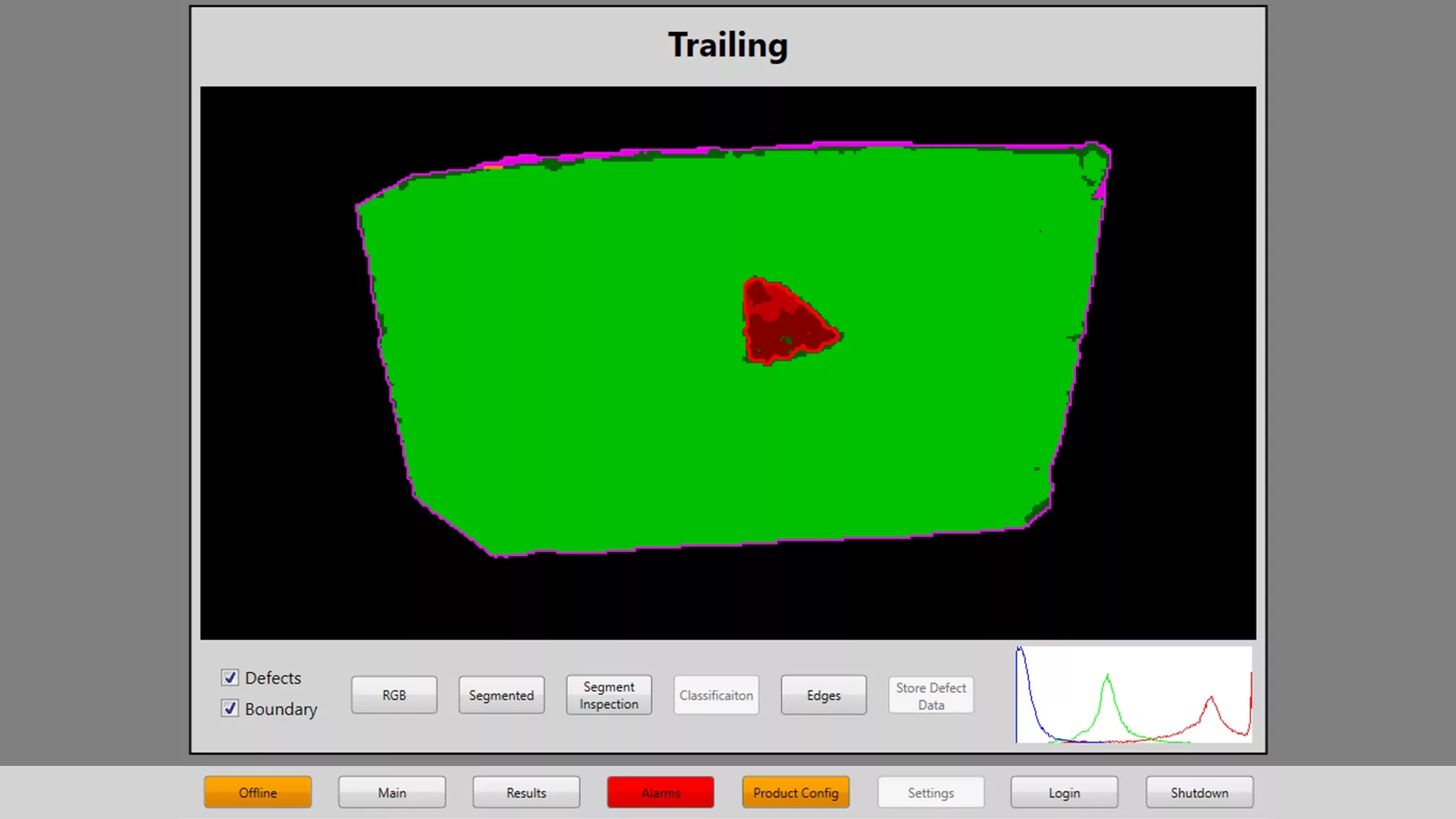

The latest model of this technology has been specifically designed to inspect each block after the bag has been removed. The DFOD inspects for visible colour defects like mould and blue plastic.

Benefit

- Provides the critical control point prior to slicing or shredding, after bag removal

- Efficient and reliable machinery with meticulous detection

- Full washdown capability makes it suitable for high hygiene areas

- Automating the cheese inspection process means reduced labour – allowing staff to be re-deployed to higher value work

Features

- Inspects all 6 sides of the block

- Suitable for full hygiene washdown requirement

- Easy to use interface

- Compact size, for easy integration into new or existing lines

Previously known as the H&C Defect and Foreign Object Detection, this was originally developed by Haden & Custance (H&C), which is now part of MHM Automation.