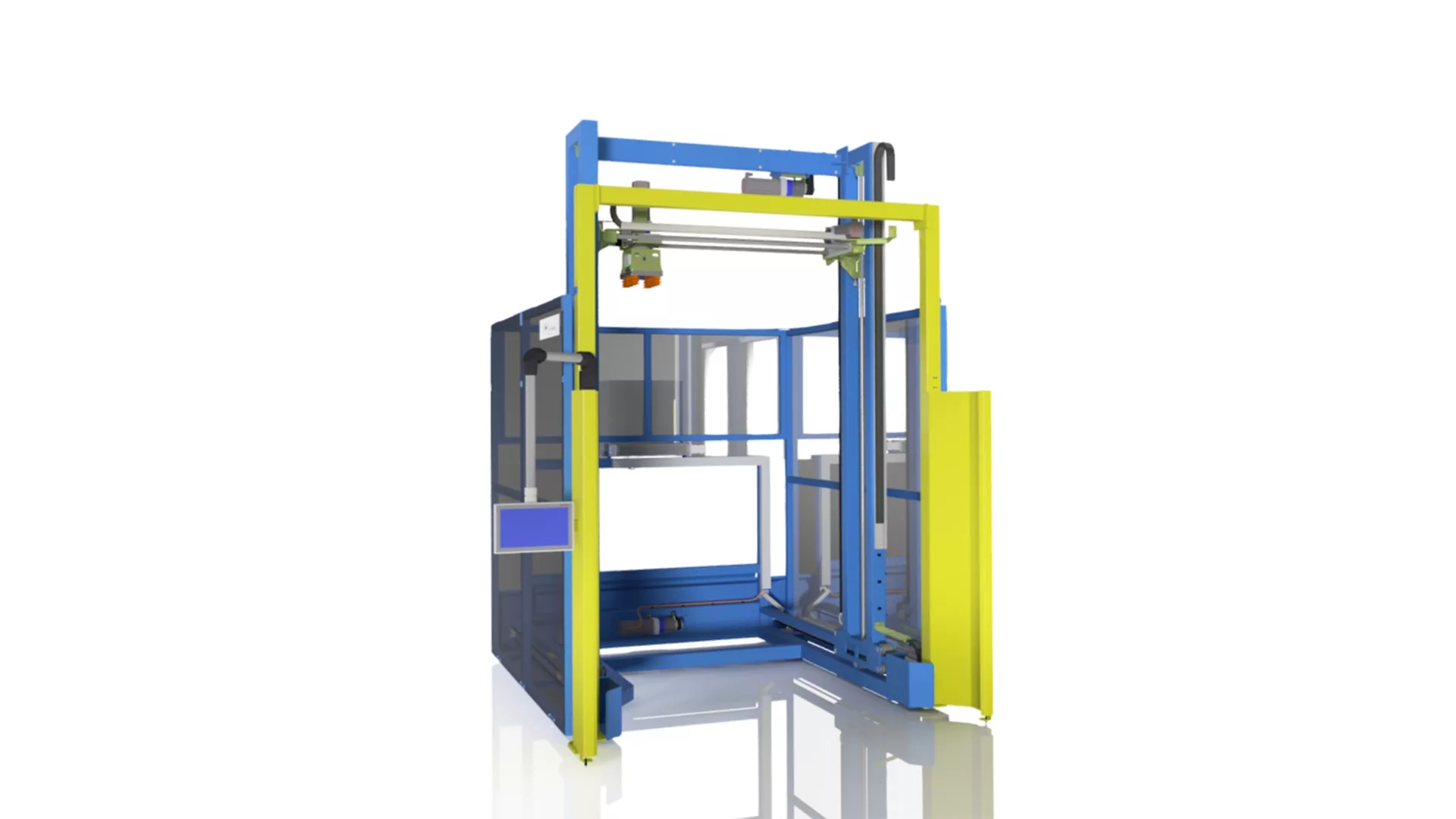

The Gantry Palletiser and De-Palletiser is a simple and robust, small-footprint palletising unit capable of handling low to high load boxes, sacks or bags.

Its gantry-style operation means a low upfront investment and quick payback in smaller-scale palletising and de-palletising operations where a robotic palletiser cannot be justified. It is easy for operators to programme via a touch-screen HMI to handle various products and pallet configurations.

Applications

- Palletising or de-palletising product in boxes, sacks or bags weighing up to 50kg (110lb)

- Lines with consistent sized product and speeds of up to 8 boxes a minute

Benefits

- Low-cost alternative to a robotic palletiser

- Reduces labour requirements, allowing staff to be re-deployed to higher value work

- Eliminates manual handling and the associated risk of injury

- Able to be used for multiple product types

- Easily installed and programmed by operating staff

- Simple, robust design minimises maintenance requirements

Features

- Simple to assemble and commission

- Safe to use, enclosed with light curtain

- Simple human machine interface (HMI) with pictorial, step-by-step instructions

- Operator can specify the product attributes and palletising pattern

- Custom-designed end effectors to suit your product

Previously known as H&C Gantry Palletiser and De-Palletiser, these were originally developed by Haden & Custance (H&C), which is now part of MHM Automation.