Industries

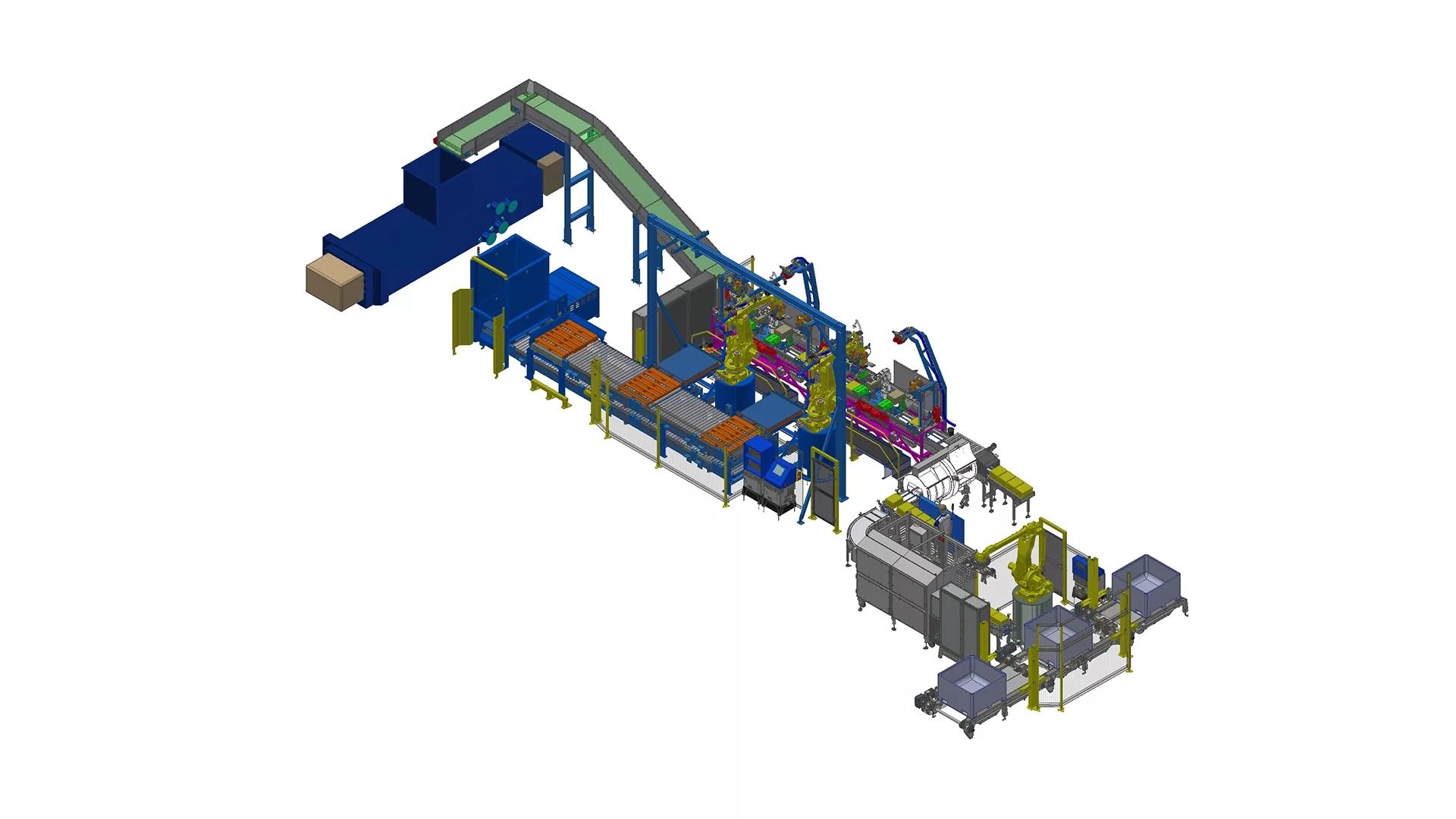

MHM Automation is constantly innovating to develop solutions that can enhance efficiency and drive growth in your business.

Learn more about our solutions for the following industry sectors.

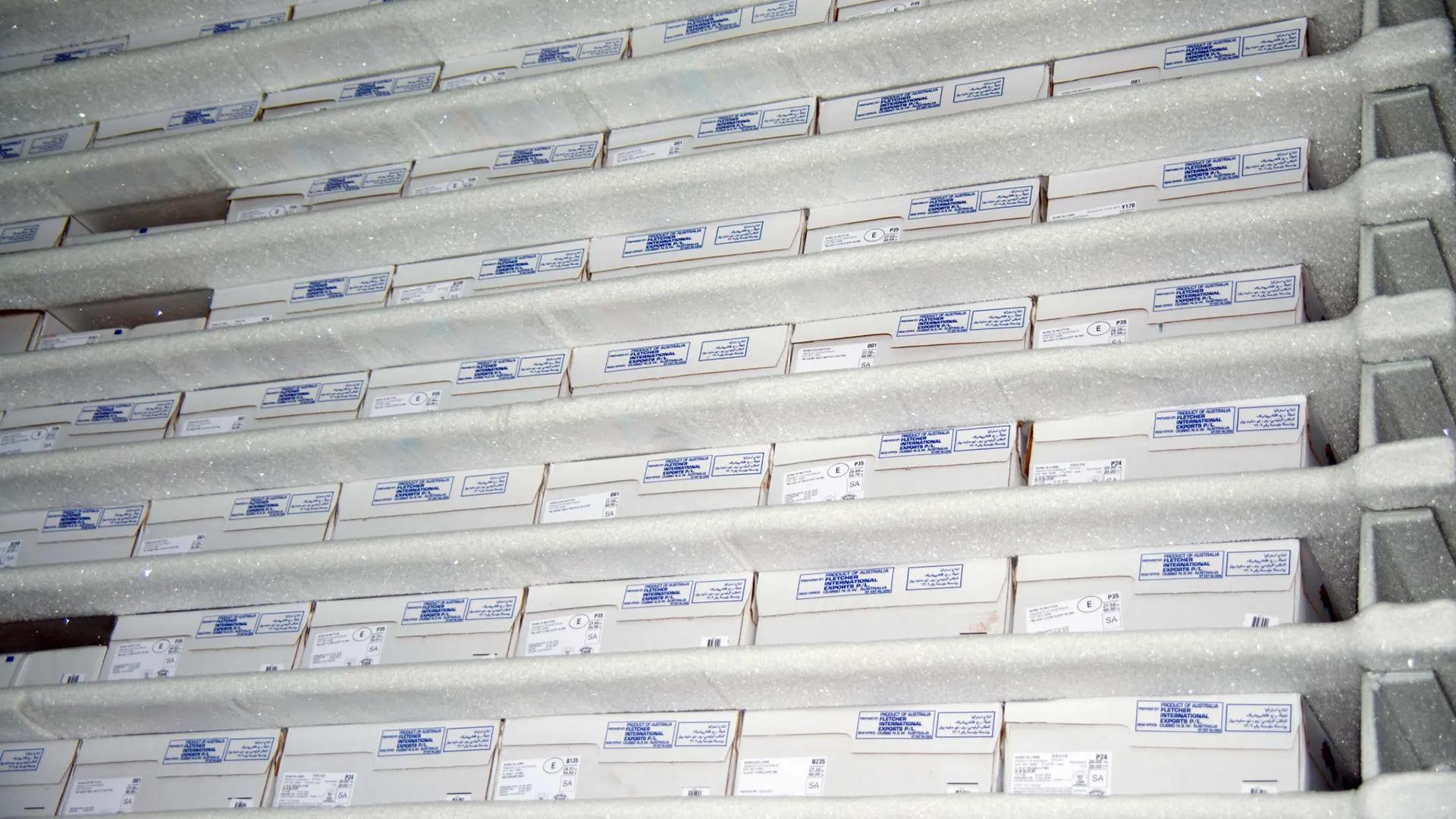

Meat & Poultry

Cheese & Dairy

Food & Beverage

Fruit & Vegetables

Grain & Feed

Timber & Sawmilling

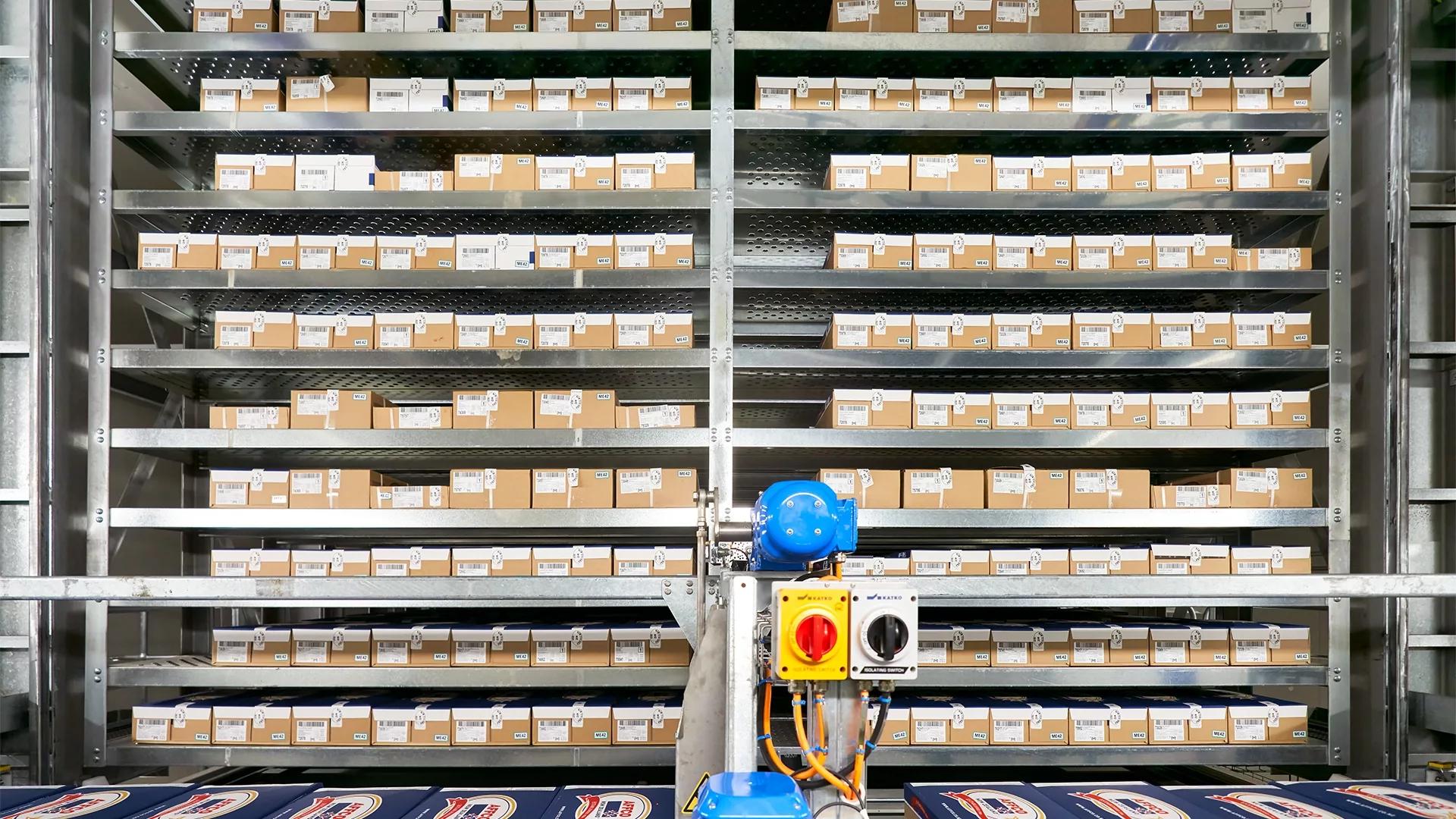

Logistics

Industrial