High performance systems for freezing and chilling packaged and unpackaged food that requires medium to long retention times.

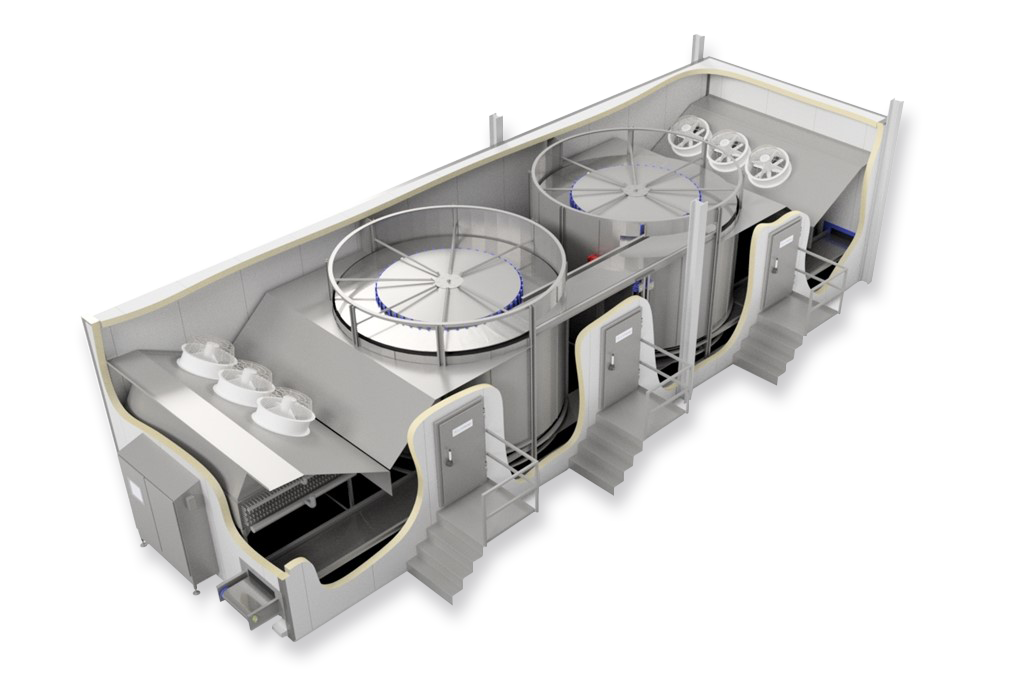

Spiral systems are available as a Spiral Freezer, Spiral Cooler, Spiral Chiller or Spiral Ambient System, available in site-built or compact factory-assembled format.

Unique individual quick freezing (IQF) technology ensures all products are chilled or frozen evenly, without excessive air speeds that could damage delicate products. Intelligent ‘guided airflow’ technology delivers circulated air, either vertically or horizontally.

MHM provides Spiral systems together with our UK-based technology partner, Starfrost.

Applications

- Meat and poultry – portioned, smallgoods, or ready-to-cook products such as tenders, nuggets, patties and meatballs

- Fish and seafood – whole, fillets, raw or cooked, battered or breaded products

- Ready meals, pizza and potato products

- Bakery items, pastries and desserts

Benefits

- Energy efficient, for low operating costs

- Space saving – small factory footprint

- Hygienic design – accessible, with deep clean sanitising stations available

- High performance – low maintenance, with long operating times

- Consistent, gentle freezing for highest product quality

- Automated loading and unloading

Bespoke

Spiral chiller or freezer systems can be designed, constructed and installed exactly to customer requirements and product specification.

Efficient

Designed with low maintenance, ease of hygiene and operational efficiency in mind. Options available to extend operating periods between defrosts up to 14 days.

Flexible

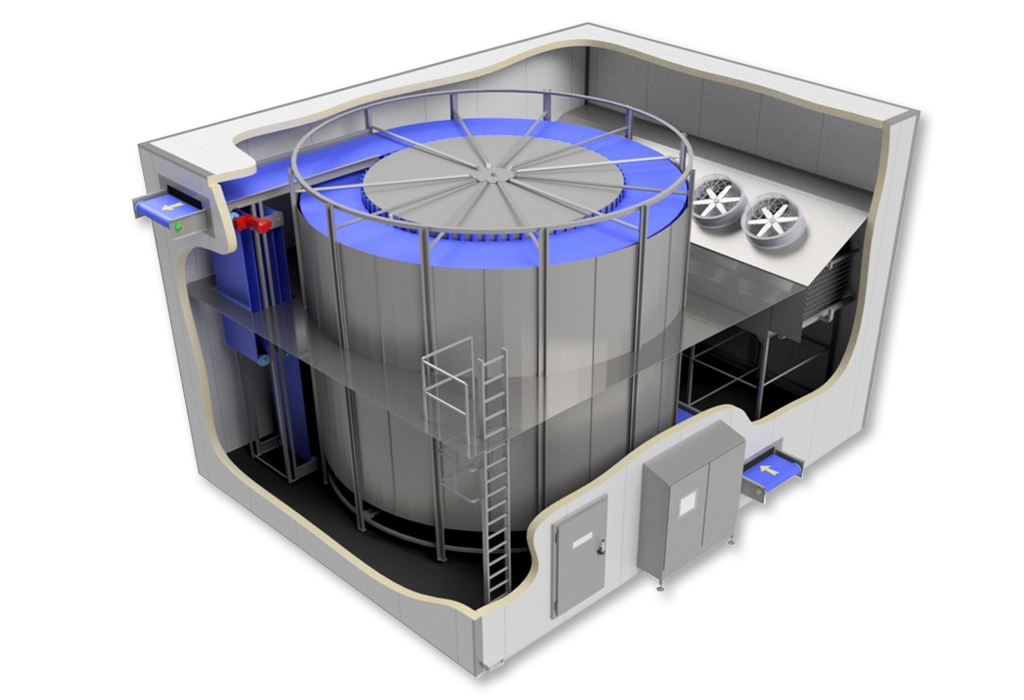

The design and construction enables modification of conveyor belt tiers and tier pitch to suit future developments and expansion.

Features

- Automated loading and unloading

- Options for horizontal or vertical airflow, to suit the product being frozen

- Enclosure design allows easy access for maintenance and service requirements

- Large freezing capacities relative to freezer footprint size

- High efficiency axial fans with anodised motors

- Evaporator tube and fin design for extended run periods

- External installation available to maximise factory space

Specifications

- Variable airflow direction for maximum cooling efficiency

- Fully welded or insulated enclosure with optional stainless steel finish inside and outside

- Evaporator with stainless steel tubes for maximum hygiene

- Direct driven fan units with the option for inverter control

- Stainless steel, plastic, low tension or direct driven conveyor belts

- Stainless steel housing to bearings

- Control panel with stainless steel enclosure, PLC and touchscreen HMI

- Complete factory pre-assembled, package systems available

- Various belt infeed/exit configurations available

- Sealed direct coupled planetary gearbox for drum drive

Product Types

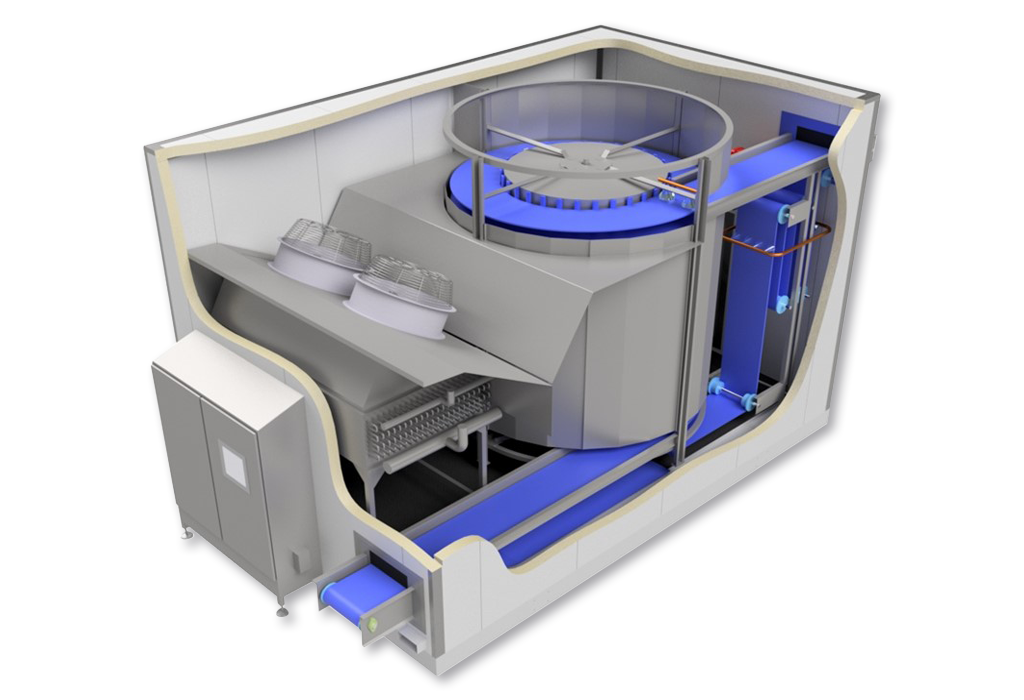

- Packaged spiral freezer: A pre-built, compact single drum spiral system. Delivered to site completely assembled and ready to operate for installation ease and reduced production downtime. Available with multiple conveyor belt width, configuration and material options.

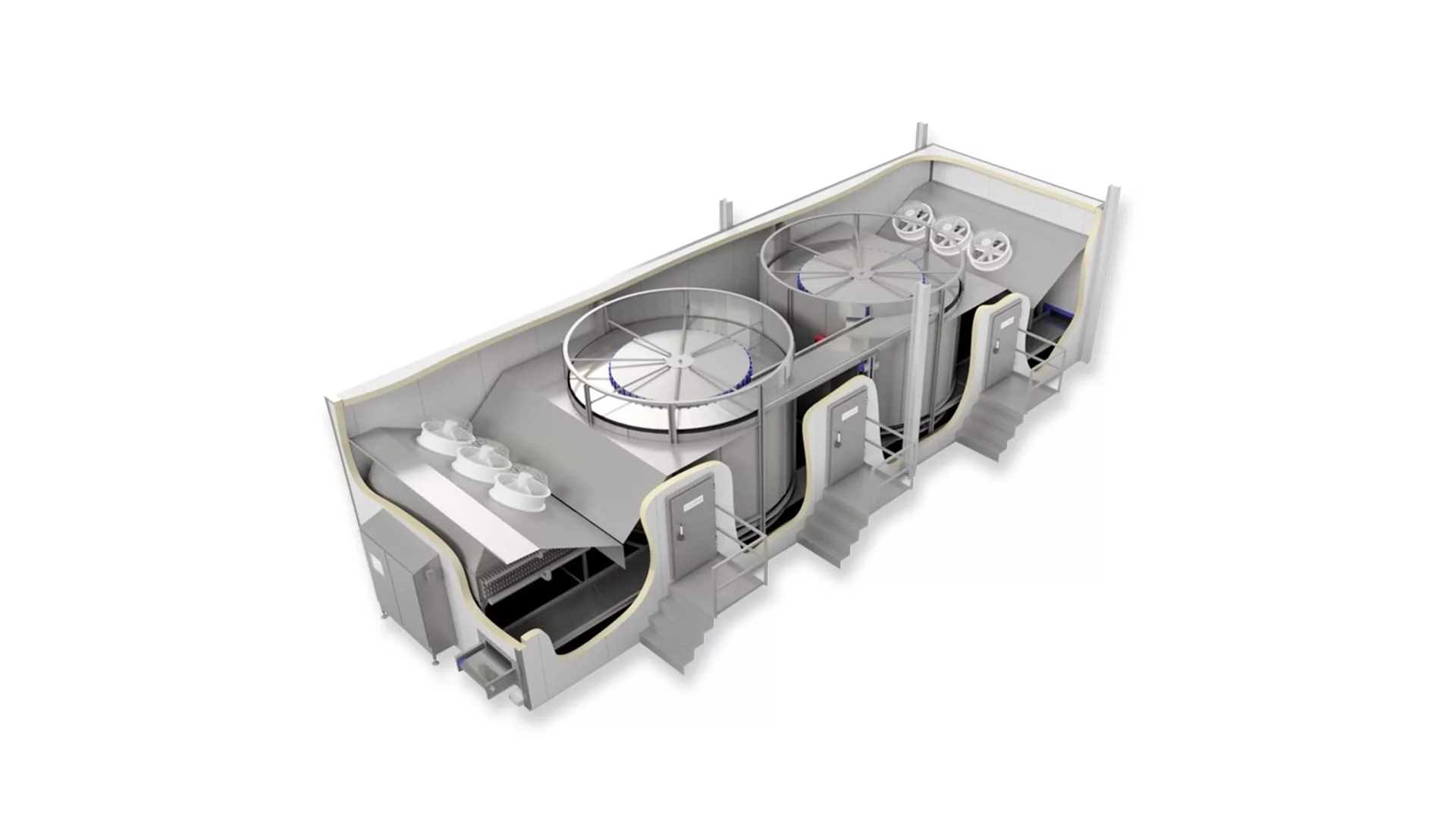

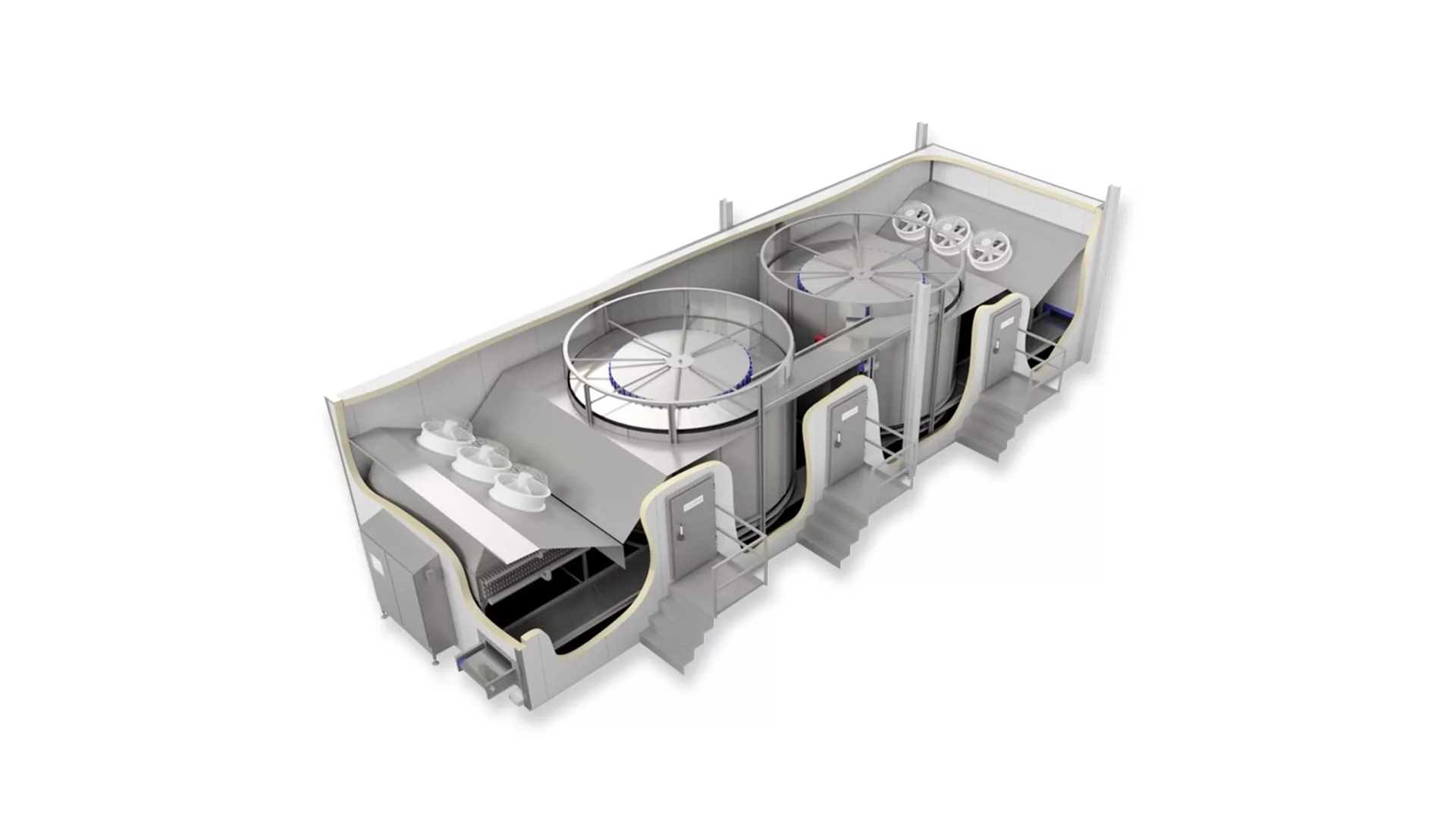

- Spiral freezer: A single drum site built high performance spiral system. The flexible and innovative design allows for a variety of width options together with different infeed and outfeed orientation to suit processing and production requirements.

- Double drum spiral freezer: A twin drum site built with a highly efficient spiral system, which can freeze large quantities of products within a limited space, maximising production area. Designed with a continuous spiral conveyor belt that allows for low infeed and low outfeed options.