Wyma Processing Lines for Onions

On demand and gentle.

On demand and gentle.

Beyond equipment, we deeply understand their unique environment and requirements. Our offerings span from core equipment to supporting structures, conveyors, electrical integration, and programming. Every element is optimised to boost overall efficiency, enhancing harvest yields and industry competitiveness.

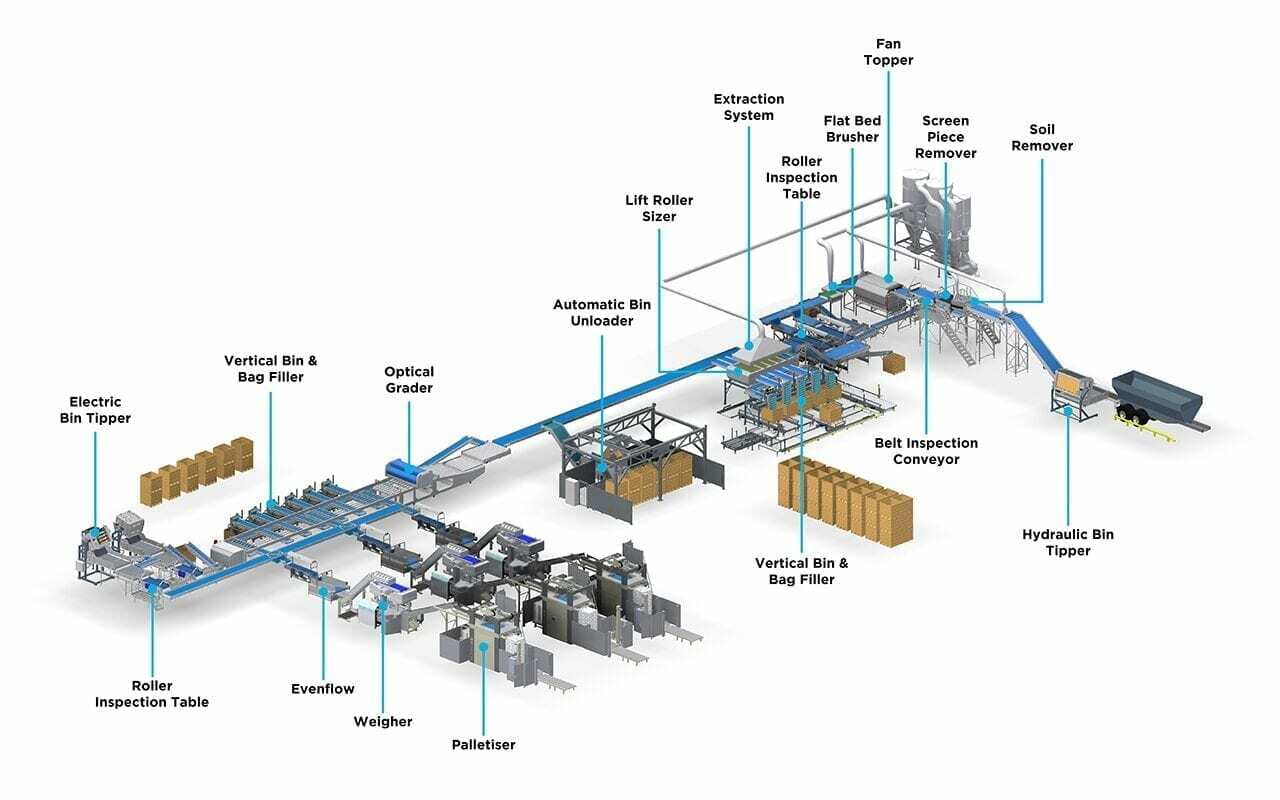

This 25-ton per hour line showcases gentle handling solutions tailored for onions to prevent bruising. Onions arrive from field trucks or bins via Manual, Hydraulic, or Electric Bin Tippers. They undergo debris removal on a Screen Piece Remover and optional manual inspection before 'topping' with a Fan Topper. Sizing into five grades is done by a Lift Roller Sizer. Produce can go directly to bins or pass through an optical grader. An Automatic Bin Management system efficiently handles empty and full bins, ensuring smooth forklift pickup. Produce going through the optical grader undergoes automated sizing and grading, leading to final manual inspection and packing. Excess produce can easily divert to bin fillers for later use.

The line presents both automated and non-automated options for Vertical Bin Fillers and Electric Bin Tippers for comparison.

Learn more: https://www.wymasolutions.com/line-solutions

Wyma post-harvest vegetable and fruit handling equipment is recognised as world leading and used by processors in more than 50 countries. We added Wyma to our portfolio through an acquisition in 2023.

The Wyma product range includes bulk product handling, washing, drying, peeling, cooling, inspection, packaging and more. Complete line solutions are available for processing carrots, onions, potatoes and fruit.