Rockit Global is an innovative New Zealand company that exports snack-sized apples packed into handy tubes for on-the-go consumption to more than 30 countries around the world.

The Challenge

When developing their new state-of-the-art apple packhouse, Rockit Global engaged MHM Automation to design and supply automated systems to enable it to increase throughput, as part of a wider strategy to scale-up its operations for global expansion. The first priority task to automate was packing apples into Rockit’s signature tube packaging, as this was a labour-intensive task to do by hand.

Our Solution

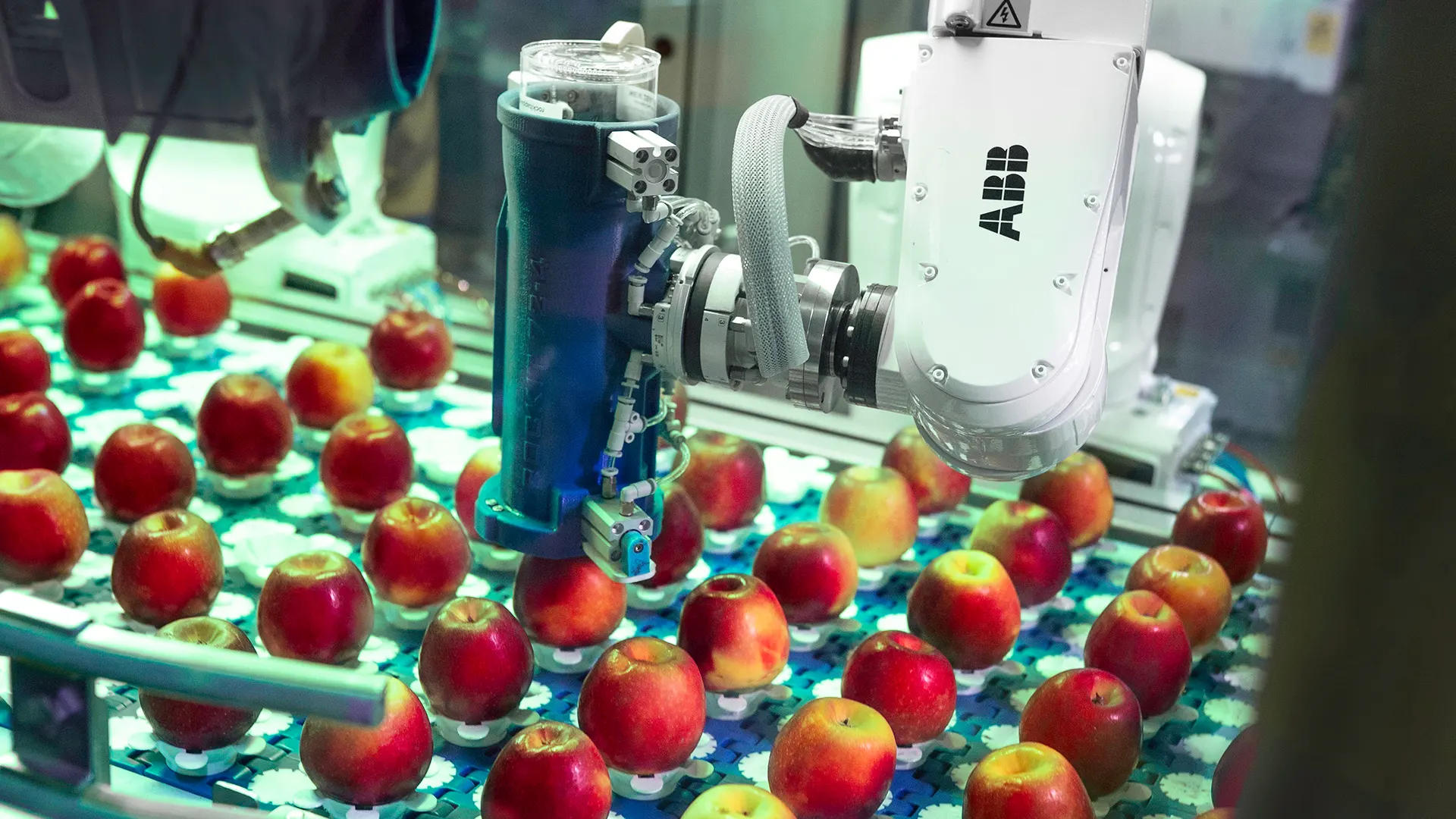

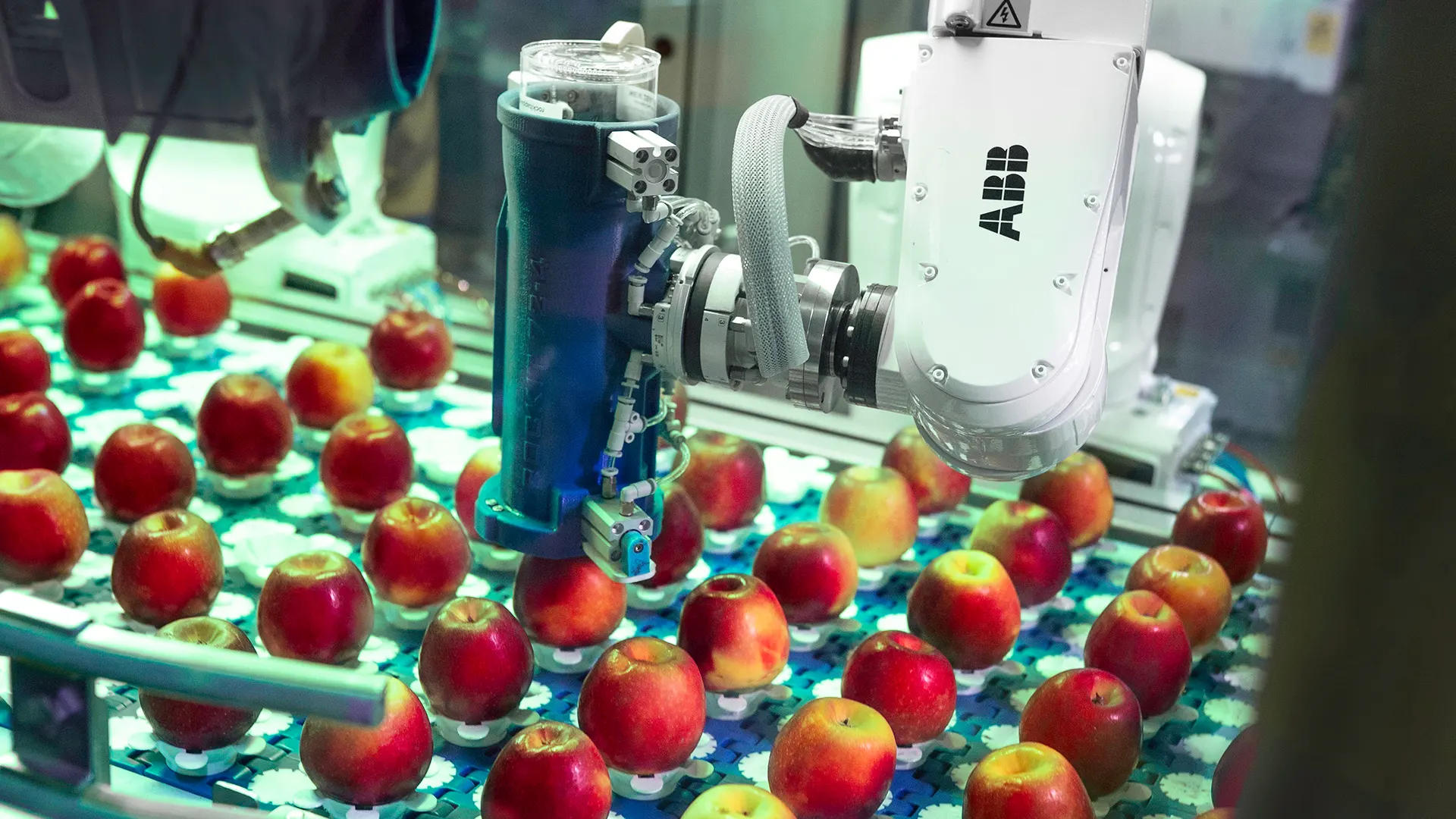

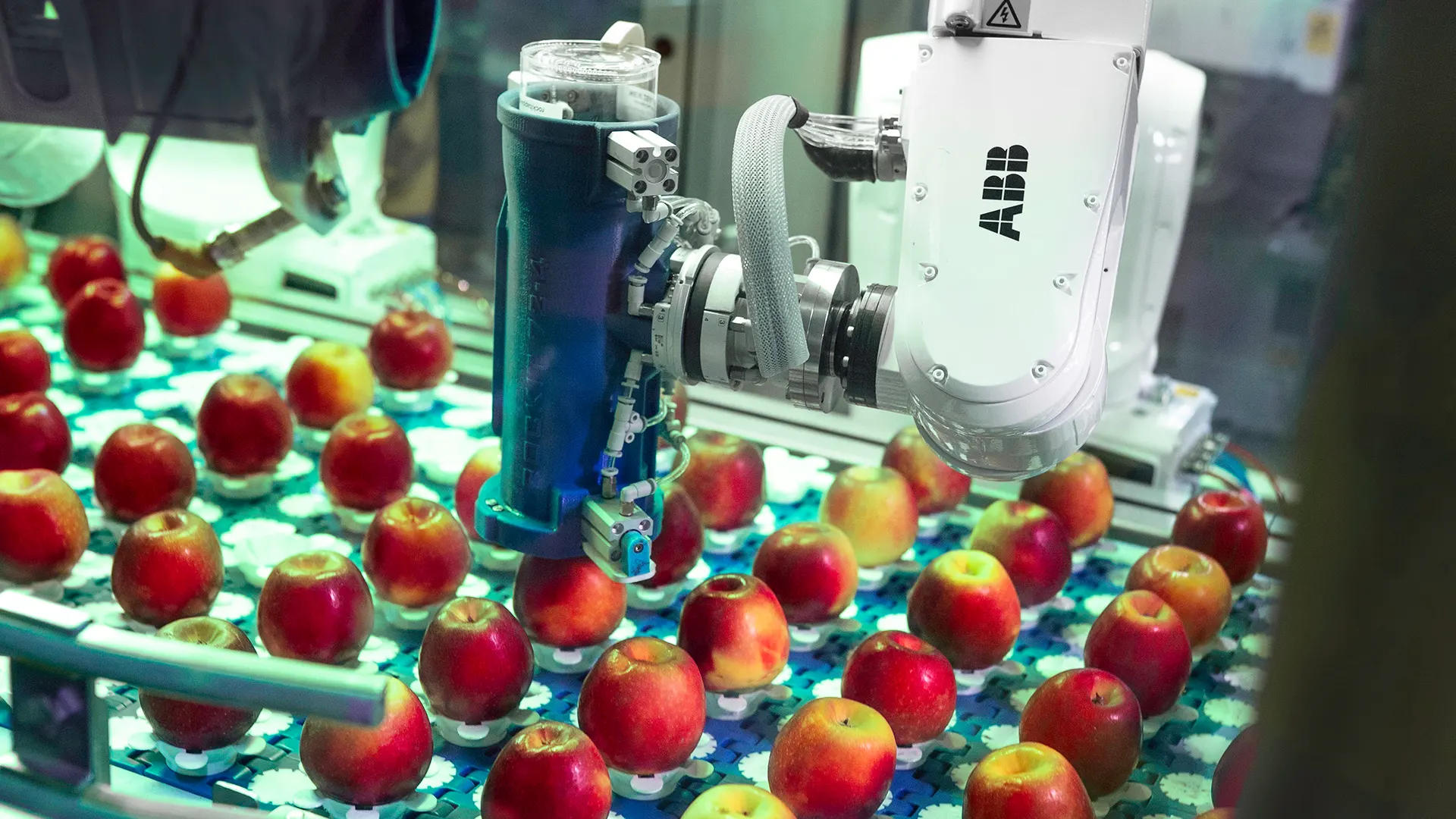

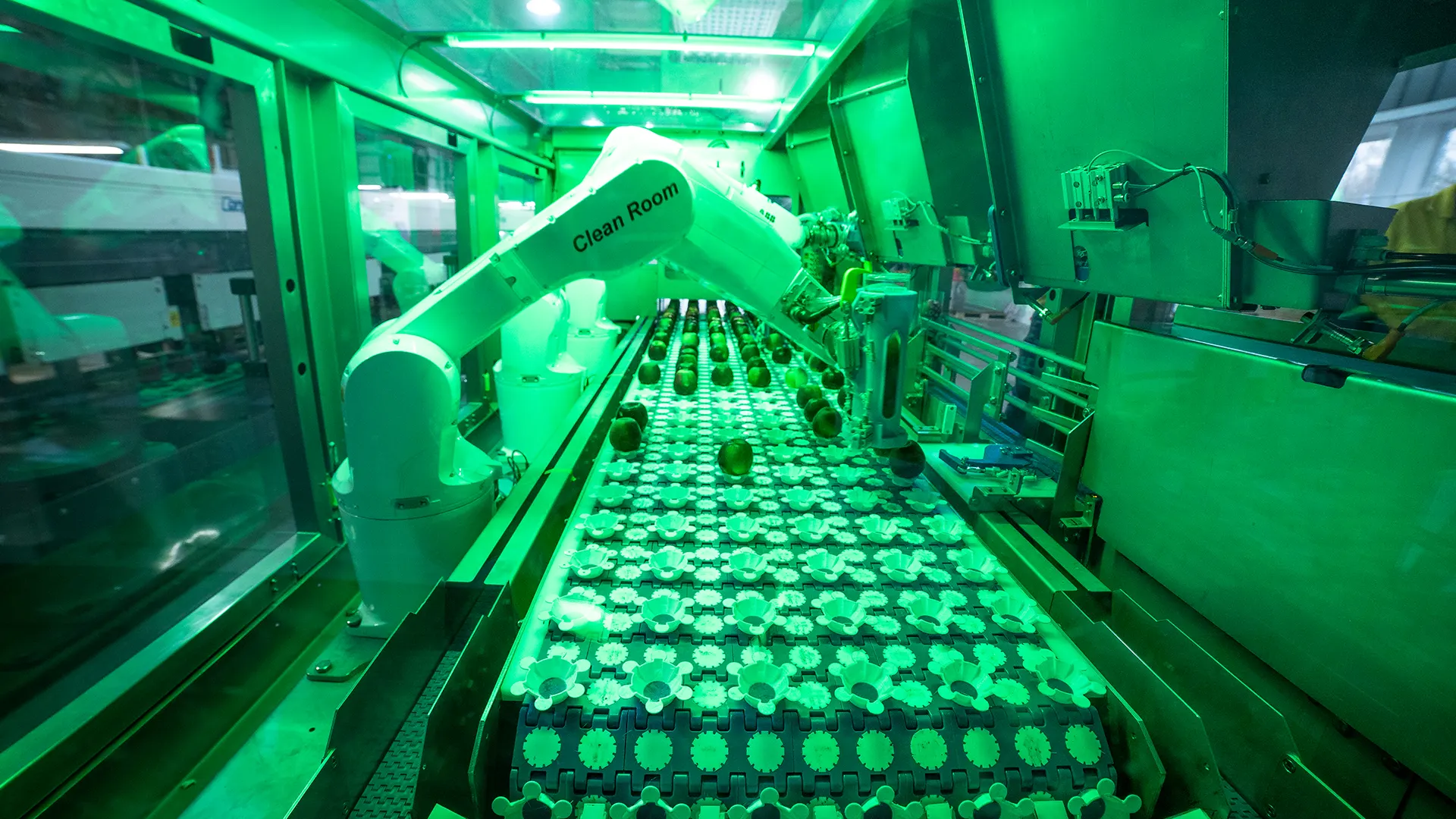

We commenced a product development process, including design, prototyping, testing and proving and then fine-tuning, before producing the final machines now installed at the plant. Four H&C apple tube filling machines have been positioned at the end of the sorting process to automate the picking and packing of apples into the plastic tubes. Fruit is orientated manually and sent along a conveyor to the machines, which each contain three ABB robots equipped with specially designed tooling to receive the tube and then place the apples into the tube. The H&C tube filling machines are a bespoke design to meet Rockit’s packing needs, including a vision system that identifies the height of each apple to allow the robots to select the right sized apples to perfectly fill each tube. Our work with Rockit continues, with focus now turning to automating the orientation and placement of apples onto the infeed conveyor, prior to filling the tubes.

The Result

Installation of the apple tube filling machines has enabled a threefold increase in packing throughput, to 20 tubes and 100 apples per minute. Rockit Global officially opened their new plant in 2021. The company expects throughput in the first year of the plant’s operations to total 100 million apples, with a goal to increase that to 500 million apples in future seasons as additional automation is introduced.

From the Client

“The biggest innovation in the plant is the robots, they’re what gets everyone excited when they walk in. While packing apples into tubes sounds simple, in reality it is incredible technology. The robots are reading the size and shape of each apple as it goes past and working out which apples to put into their tube to maximise the fill of that tube; it’s really clever stuff.”

MARK O'DONNELL

CEO, ROCKIT GLOBAL