Wyma Processing Lines for Potatoes

Providing a complete line solution.

Providing a complete line solution.

Beyond equipment, we deeply understand their unique environment and requirements. Our offerings span from core equipment to supporting structures, conveyors, electrical integration, and programming. Every element is optimised to boost overall efficiency, enhancing harvest yields and industry competitiveness.

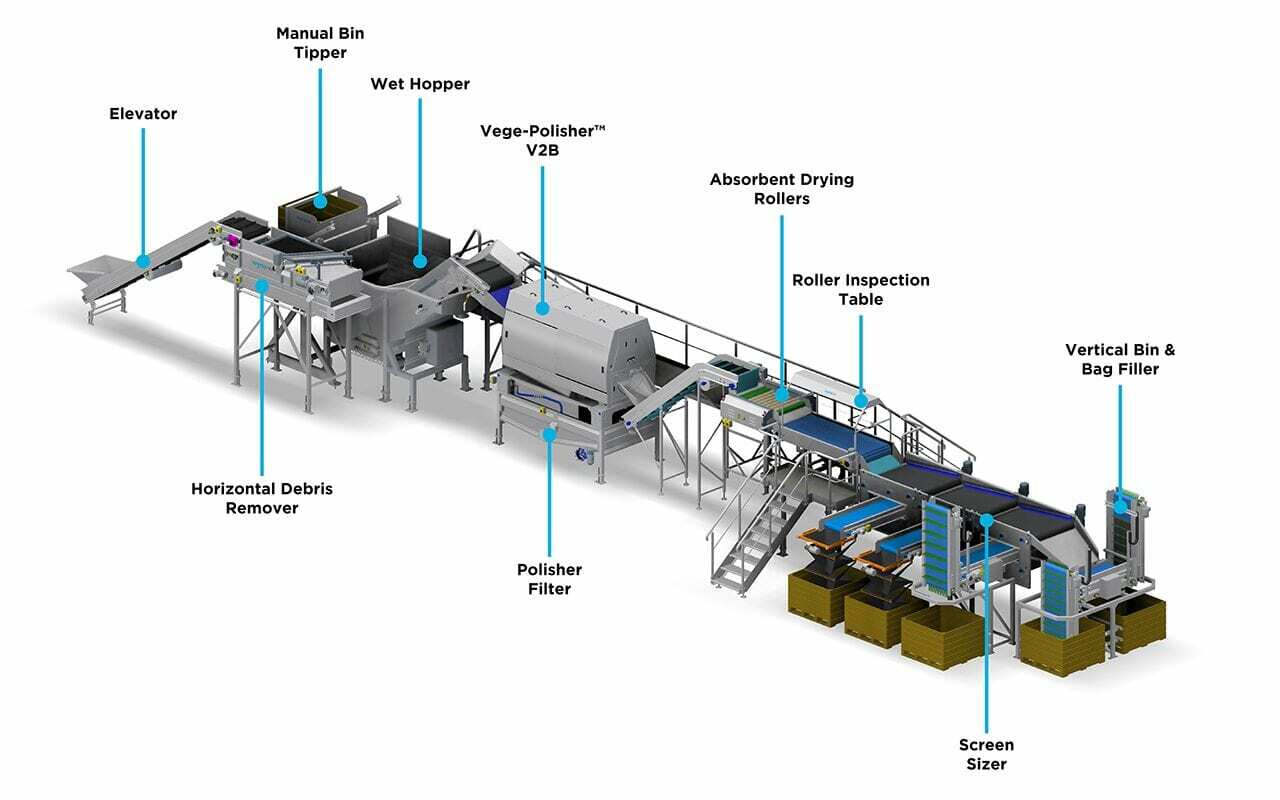

This 5-ton per hour potato wash line offers a straightforward and cost-efficient post-harvest solution. Potatoes can enter via an Elevator or a Manual Bin Tipper into a Wet Hopper for soaking before washing and polishing in a Vege-Polisher™. The integrated Polisher Filter cleans and recycles wash water, minimising usage. Potatoes go through Absorbent Drying Rollers for moisture reduction, followed by inspection and sizing using three Screen Sizers. Sorted produce can be packed using a Vertical Bin & Bag Filler or directly from the screen sizer output conveyors.

This line configuration would ideally suit a smaller scale grower, or packer, sourcing produce directly from harvest trucks, sacks or field storage bins.

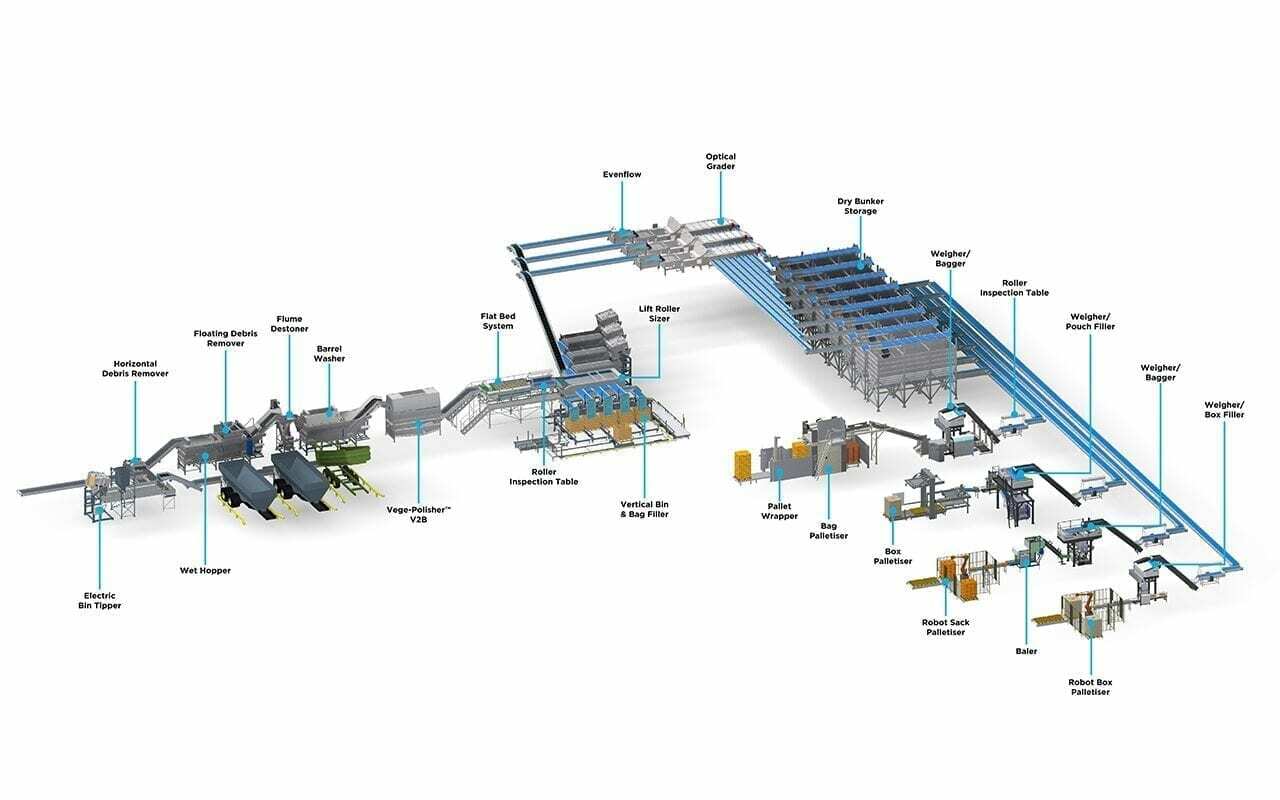

This 25-ton potato line offers versatile receiving: from harvest trucks or via Electric Bin Tipper from storage bins. It starts with a Horizontal Debris Remover, followed by soaking in a Wet Hopper and stone removal in a Flume Destoner. Washing and polishing are done with a Barrel Washer and Vege Polisher.

Water recycling reduces usage through a Water Recycling System; a Mud Separator removes excess soil. A Flat Bed Dryer reduces moisture, followed by manual quality checks on a Roller Inspection table. The Lift Roller Sizer enhances efficiency for Electronic graders, while Vertical Bin Fillers manage overflow.

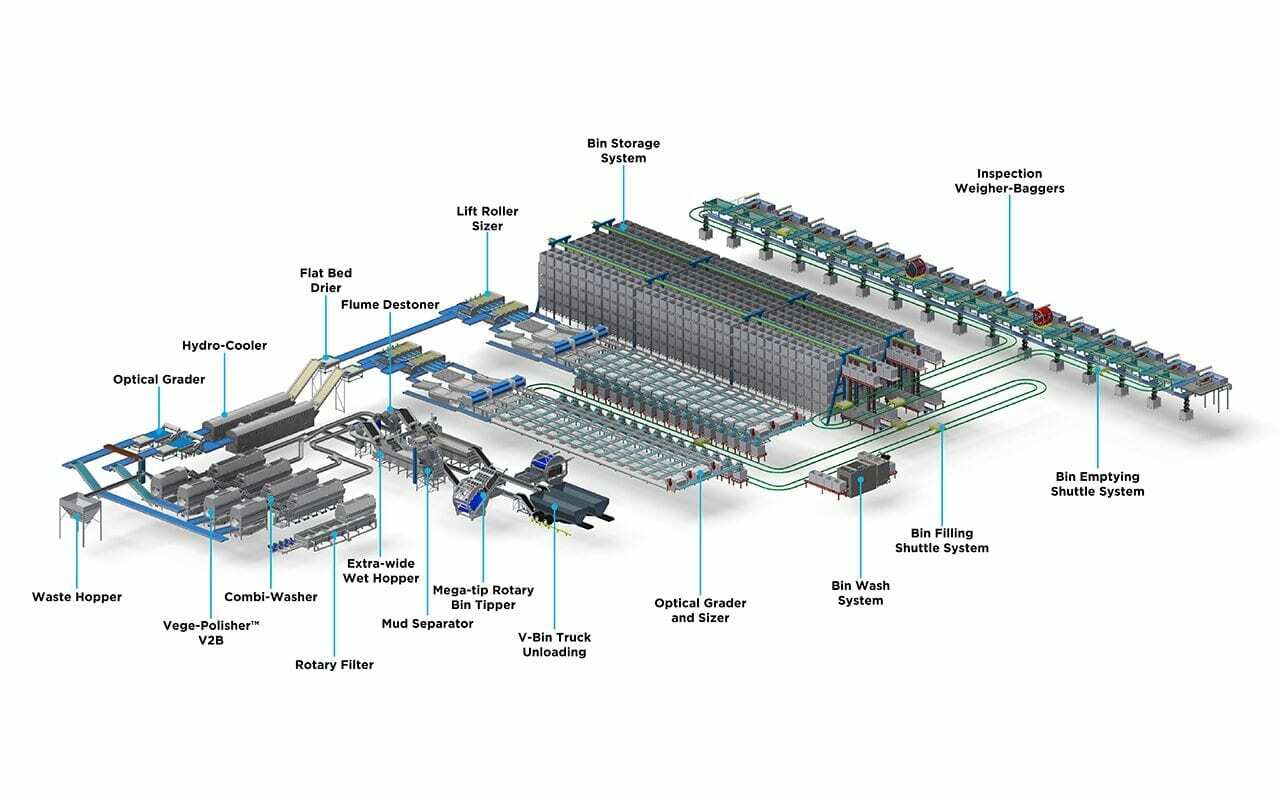

Post Electronic grading, products are stored in Dry Bunkers before diverse packing options like Bagging/Palletising, Pouch Filling/Boxing, Bagging/Baling, and Box Filling/Palletising, meeting various retail and consumer needs.This 90-ton potato line handles large produce volumes with precision and scale. It receives from storage bins or harvest trucks, then undergoes soaking, destoning, washing, and polishing. A comprehensive flume network is supported by a Rotary Filter water recycling system. Potatoes pass through an Optical Grader to dual Hydro-Coolers for extended shelf life. Precision sizing and grading occur through a Lift Roller Sizer and Optical Grading system. Sized produce moves via an Automated Bin Handling System for storage or direct inspection, weighing, and bagging. Configurations vary based on individual needs and environmental factors.

Learn more: https://www.wymasolutions.com/line-solutions

Wyma post-harvest vegetable and fruit handling equipment is recognised as world leading and used by processors in more than 50 countries. We added Wyma to our portfolio through an acquisition in 2023.

The Wyma product range includes bulk product handling, washing, drying, peeling, cooling, inspection, packaging and more. Complete line solutions are available for processing carrots, onions, potatoes and fruit.