Log Processing Equipment

Handling and processing equipment for large and small diameter logs.

Handling and processing equipment for large and small diameter logs.

This includes log cranes (rotary, gantry, goliath), debarkers (Drum, Ring, Rosserhead), log merchandisers, log sorters and all the associated log decks, log conveyors and handling equipment. We work closely with several suppliers and design and manufacture whatever equipment we can provide cost effectively.

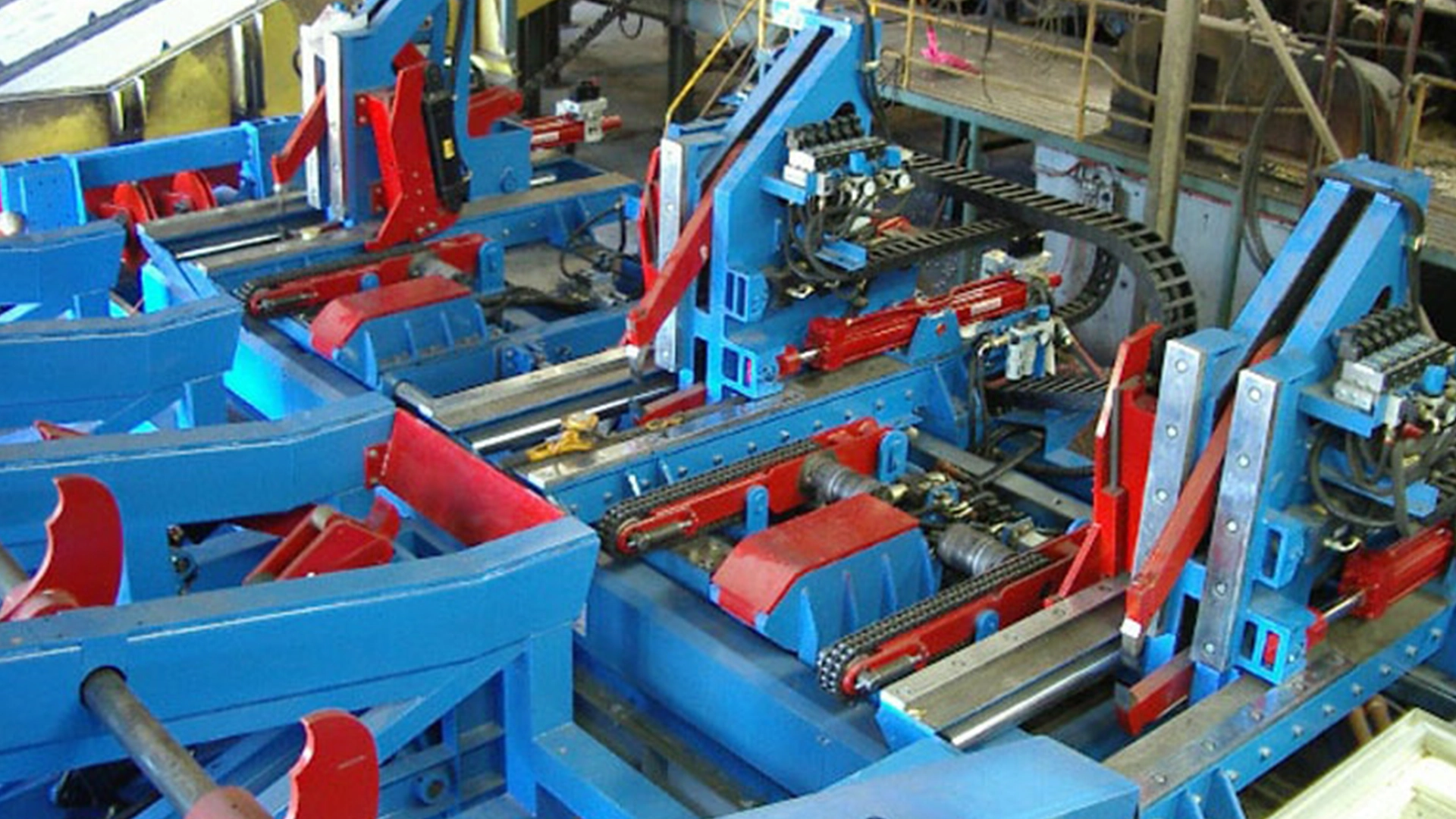

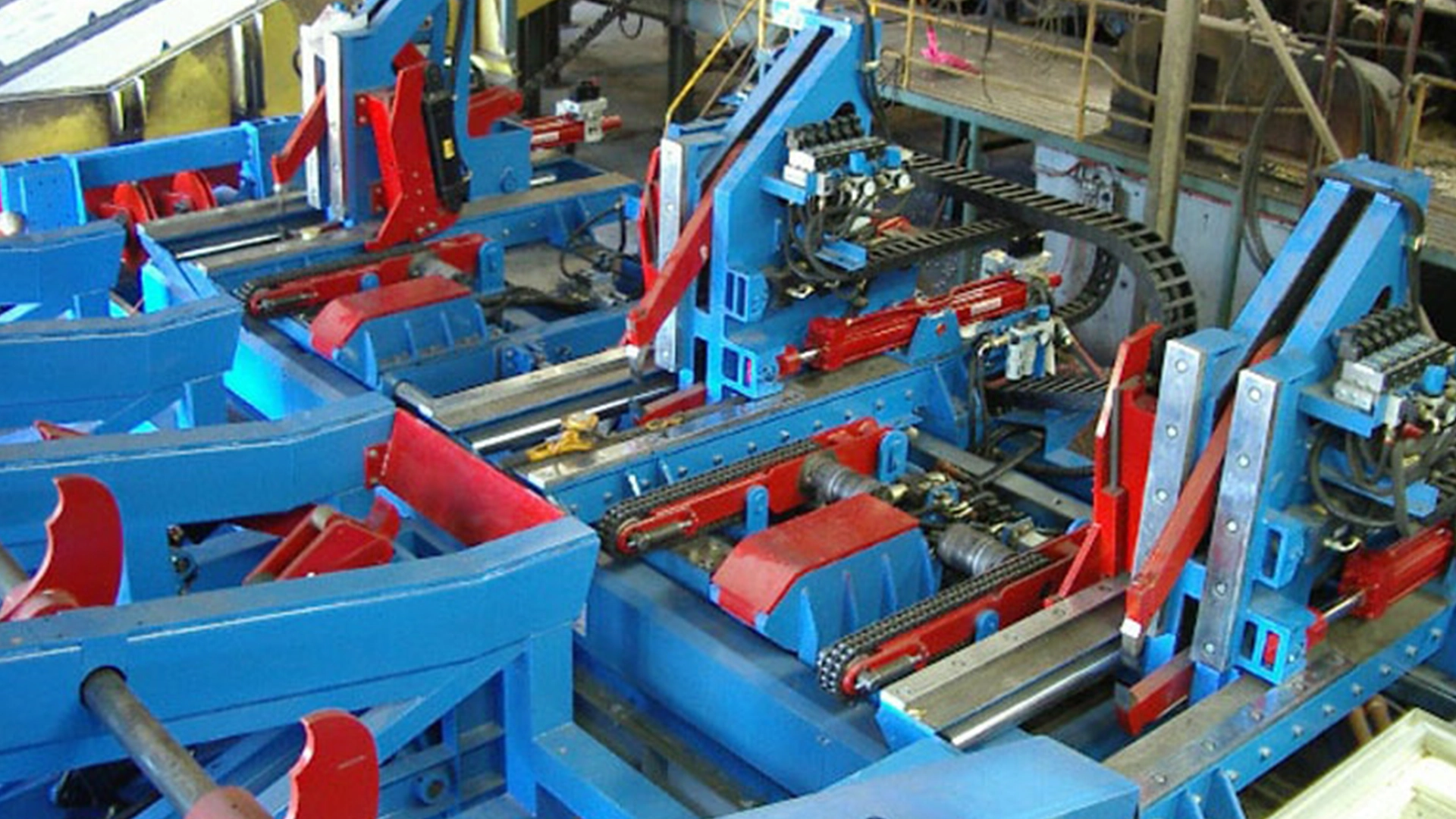

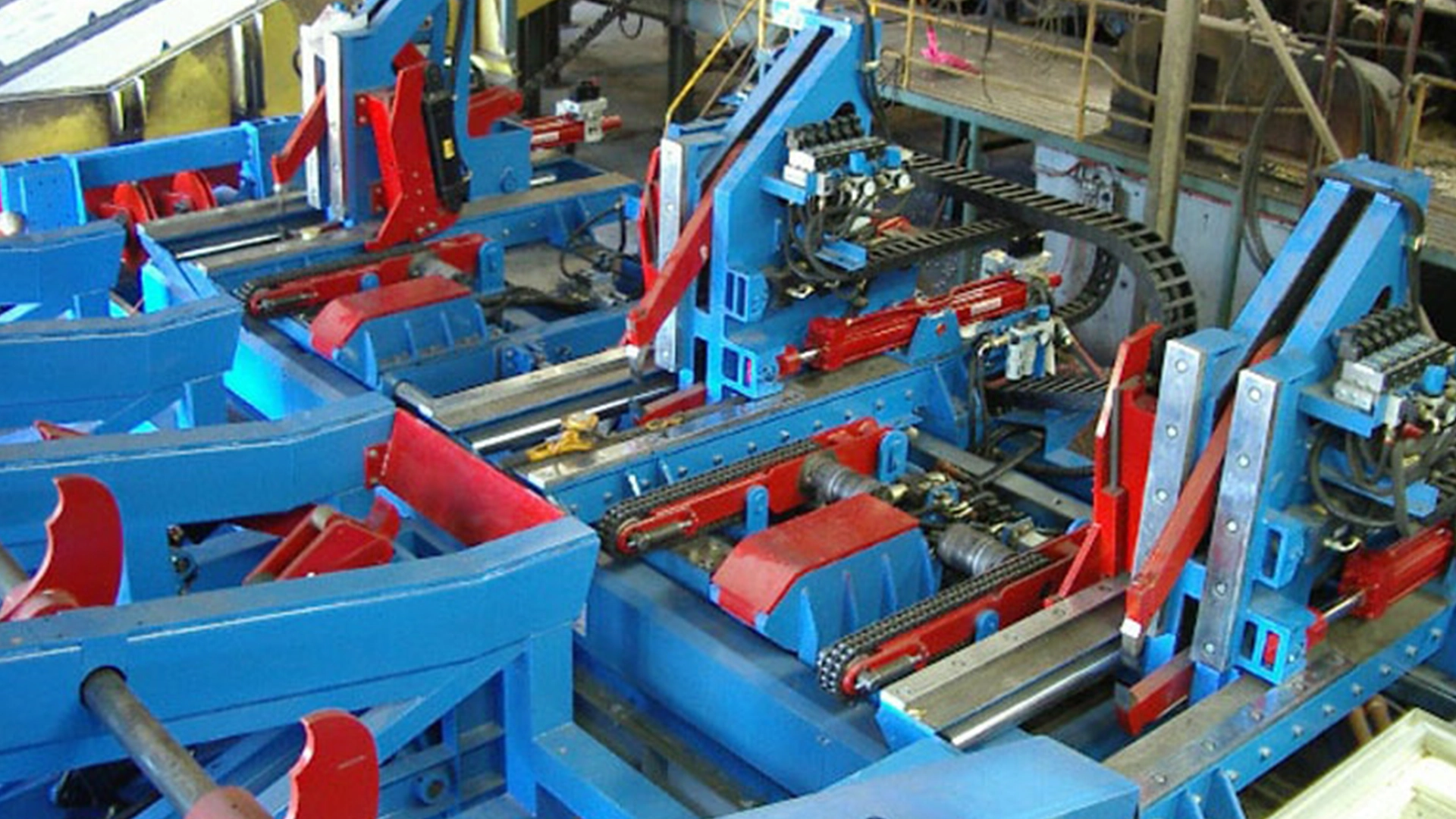

MHM Automation manufactures the Wilson range of log carriages and associated items such as:

MHM Automation represents a number of World Leading Suppliers of small log lines including Optimil of Canada.

The systems can include the following:

When it comes to debarkers MHM Automation is the “one stop shop”. MHM Automation has the complete range of debarking machines available.

This includes a Rosser Head style debarker as suited for very low production and large logs which is of our own design. We have the full range of Nicholson Ring Debarkers from medium capacity up to the world’s fastest model of ring debarkers and from very small logs up to large diameter logs. Nicholson is a world leader in the design and manufacturing of ring debarkers and have done so for the past 60+ years.

In addition we can also offer Drum debarkers of different designs for the debarking of pulp logs typically of a small size and for a range of log species.

Associated with these items we offer the full range of infeed & outfeed systems and complete log yards, log Merchandisers and log sorters with full log optimization.

We have a Service Technician whom is factory trained in setting up; maintaining and for Client Training specifically on the Nicholson Range of Debarkers. We carry an extensive range of Debarker Spares in both our Auckland and Melbourne Branches.

MHM Automation has been manufacturing Rosser Head Debarkers for many years.

The logs are rotated singularly in a cradle with driven rollers while a spinning cutter head passes over the log and moves along its length.

The Rosser head debarker works similar to a lathe in the method it removes bark. Rosser head debarkers are primarily used in slower speed operations, in hardwood mills or on larger crooked logs.

MHM Automation represents a world leading supplier of Ring Debarkers namely Nicholson Manufacturing of Canada.

Nicholson have been developing debarkers for over 60 years and can boast the fastest debarkers in the world with debarking speed exceeding 150mpm. The design of their debarking ring and tool arms provides excellent debarking to the equal of any other on the market today. Indeed others often require fitting two rings to achieve the same debarking performance.

The Debarkers that are currently under production start from a new low speed and simple debarker known as the R2; the A1 Model is a heavy duty debarker for rough and larger logs with a reasonable feed speeds. You can have either the fabricated chain feed or the roll feed unit. An example of the later was recently installed at the Timberlands, KPP site in Kaiangaroa where the application calls for both speed (up to 90mpm+); a lifting ring design and to have the ability to process tree stem length logs (up to 38m long) of quite rough quality on a 24 hour / 7 day a week basis.

The Slow to Medium speed debarker range is the A6 and there are many examples of this model in Australia and N Z.

The A5 model which was developed some years ago is still available as the A5C for some ring sizes and offers excellent debarking at quite high speeds but at a discount to the latest and fastest model the A8.

The A8 is the Rolls Royce of Ring Debarkers and has no direct competitor for strength of design, speed of debarking, accessibility for maintenance, and reliability. Although quite a new model there are now well over 100 machines of this model world-wide and we have supplied 3 into our market in the last few years.

MHM Automation works closely with overseas suppliers when it comes to drum debarkers, radial cranes and log merchandisers.

Drum debarkers with XHD design, VFAC electric drives & various lifter arrangements, allow for debarking perfection while reducing white wood losses in an easily maintainable power system.

Drum Debarkers are designed, engineered, and manufactured to meet the most rigorous standards in the industry. This high-production equipment is energy-efficient, easy to maintain, and can dramatically increase throughput to the highest level in the industry. Operation costs are reduced and production rates are increased for a competitive advantage.

Available in a range of sizes from 2.7m – 4m diameter sizes to any length for the appropriate sized wood. The rubber-tire supported drums meet the industry’s highest quality specifications, with up to 38mm (1.5 inch) shell thickness; 7% – 11% bark slot area; 30,000 lb. rated axle assemblies; plus maintenance and safety features that are extra on competitors drum systems.

Mobile Drum debarking systems are also available and overall we can supply a Drum debarker that can process from as little as 15 tonnes/hour up to 400 tonnes/hour.

Whatever your debarking needs are we at MHM Automation have a solution for you.

MHM Automation can offer a complete range of wood chippers.

This includes both Drum and Disc Chippers from as small as 15cu.m.chips/hr up to and excess of 1000cu.m.chips/hr and up to 2000KW power.

We offer the complete range of Bruks Drum Chippers which includes the former Klockner range. Included are both horizontally fed and drop fed chippers with drums up to 2 meters in diameter. These chippers are ideal for roundwood, slabs, edgings, reject boards, trim ends and veneer residue.

Bruks Drum Chipper EN 0509: Bruks new generation drum.

We also offer the Carmanah range of disc chippers from 55” disc diameter up to 117” diameter. The Carmanah chippers incorporates designs from the former CAE and Nicholson.

Carmanah offers DISC chippers in 3 distinct styles: