Wyma Processing Lines for Carrots

Providing a complete line solution.

Providing a complete line solution.

Beyond equipment, we deeply understand their unique environment and requirements. Our offerings span from core equipment to supporting structures, conveyors, electrical integration, and programming. Every element is optimised to boost overall efficiency, enhancing harvest yields and industry competitiveness.

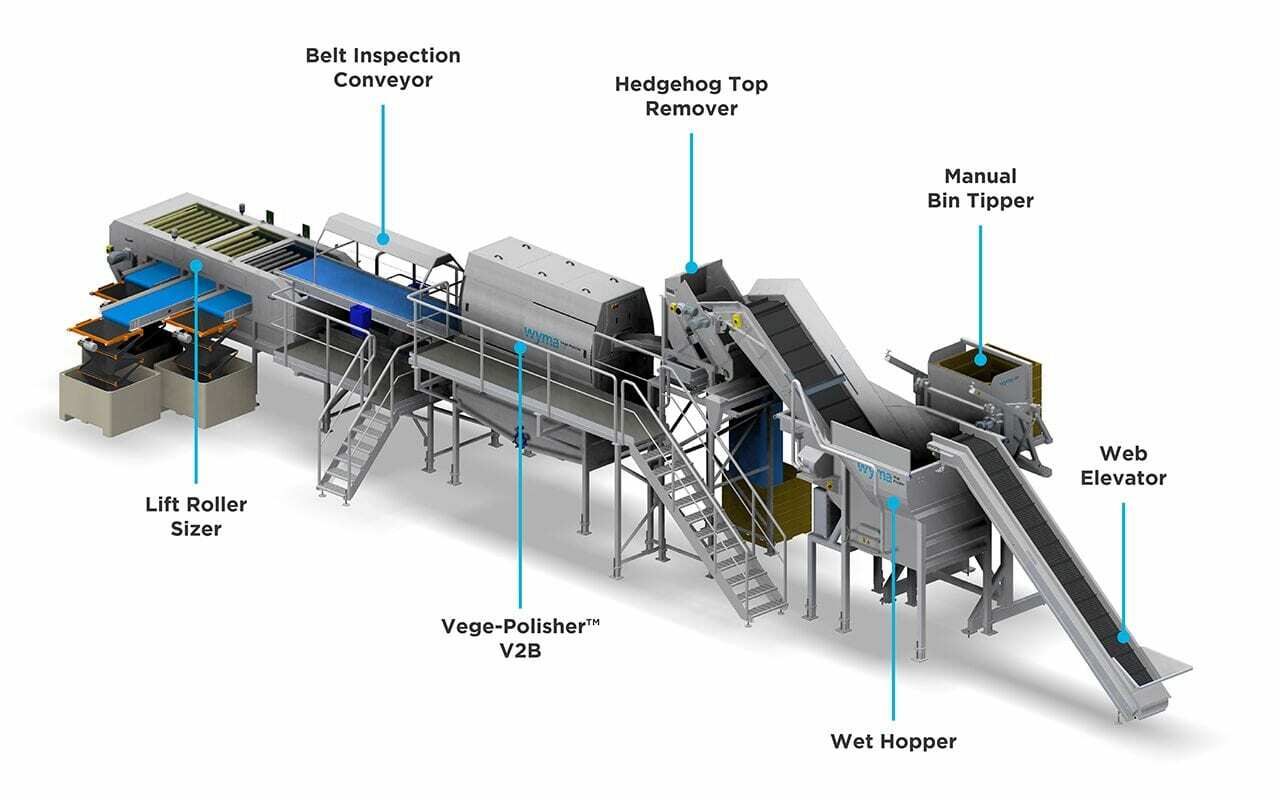

This 5-ton per hour carrot wash line offers flexibility and high performance for smaller post-harvest operations. Produce can enter via an Elevator or a Manual Bin Tipper into a Wet Hopper (2-ton capacity shown). After soaking, the produce moves to a Hedgehog Top Remover for efficient separation from tops and weeds. Carrots are then washed and polished in a Vege-Polisher™ with water cleaned and reused through the integrated Polisher Filter, minimising water use. The graded produce, categorised by diameter, is gently transferred to bins for separate packing or can be directly packed on the line after grading.

This line configuration would ideally suit a smaller scale grower or packer, sourcing produce directly from harvest trucks, sacks or field storage bins.

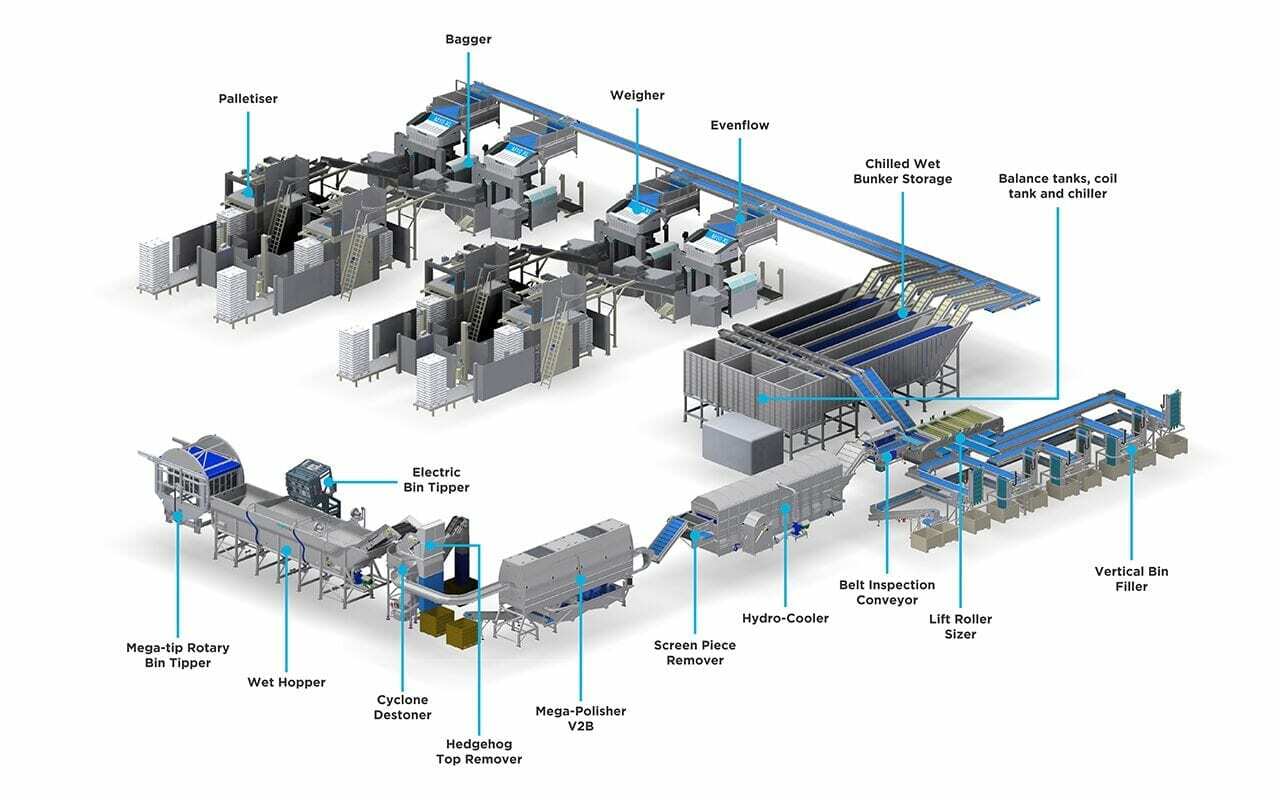

This 20-ton per hour carrot line efficiently handles different bin sizes: 4-ton bins via the Mega-Tip Rotary Bin Tipper and 1-ton bins via the Electric Bin Tipper, both loaded manually by forklift. Carrots enter the Wet Hopper, undergo soaking, move through the Hedgehog Top Remover for de-stoning, and enter the Mega-Polisher for polishing. Cooling in a Hydro-cooler precedes quality inspection and sizing. Sized carrots can go straight to Vertical Bin and Bag Fillers for dry storage or to Wet Bunkers for short-term storage. They can then be commercially packaged through an integrated Weigher, Bagging, and Palletising system.

A line configuration such as this would suit a medium-sized packhouse where capacity, cooling and automation are important.

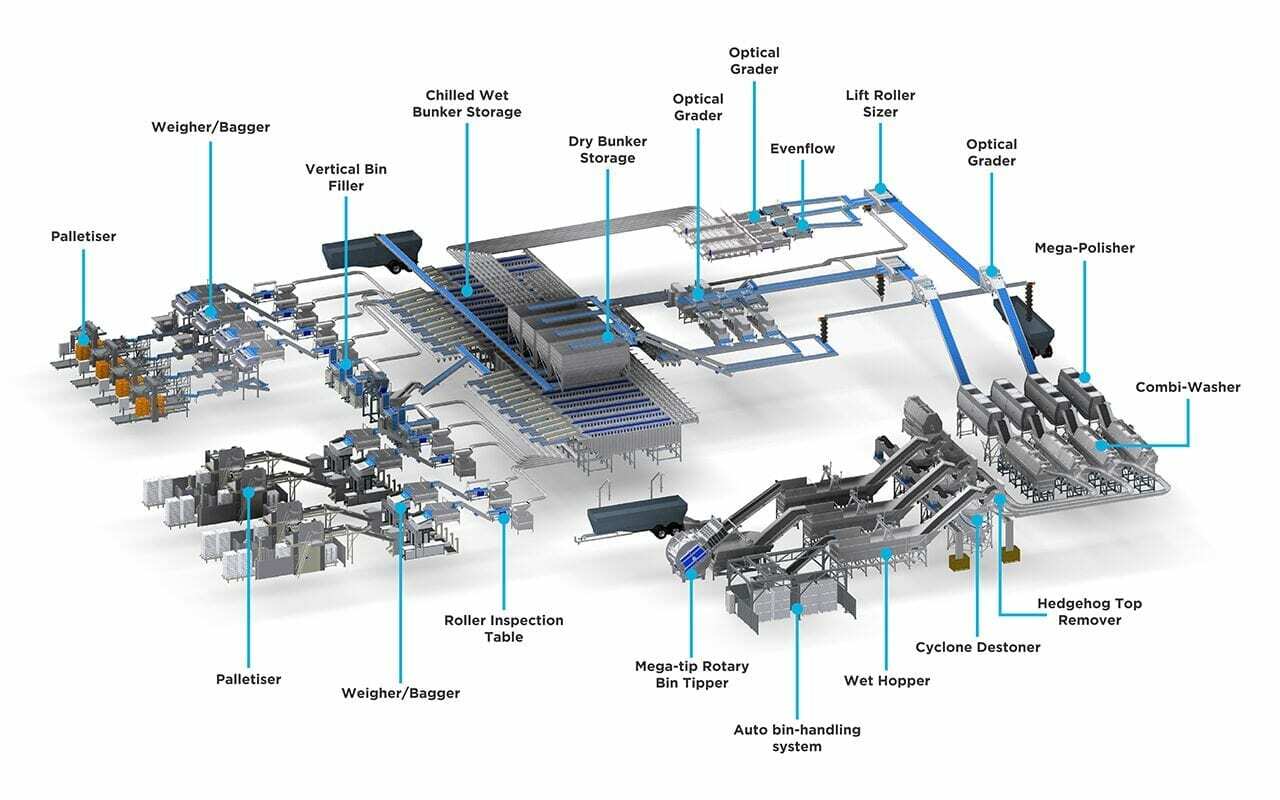

In this 45-ton per hour line, precision and scalability are key. It features three receiving systems: Truck Washout, Bin Tipper, and an automated bin-handling setup. Carrots enter Wet Hoppers, undergo soaking, move to the Hedgehog Top remover, and are de-stoned. They're then polished in Mega-Polishers before mechanical and optical sorting into desired grades. Chilled Wet Bunkers or Dry Bunkers store the sorted carrots before final inspection and packaging. Options include using a Vertical Bin Filler or an integrated Weigher, Bagging, and Palletising system for commercial packaging.

A line configuration such as this would suit a larger packhouse where scale, demand management and automation are important.

Learn more: https://www.wymasolutions.com/line-solutions

Wyma post-harvest vegetable and fruit handling equipment is recognised as world leading and used by processors in more than 50 countries. We added Wyma to our portfolio through an acquisition in 2023.

The Wyma product range includes bulk product handling, washing, drying, peeling, cooling, inspection, packaging and more. Complete line solutions are available for processing carrots, onions, potatoes and fruit.