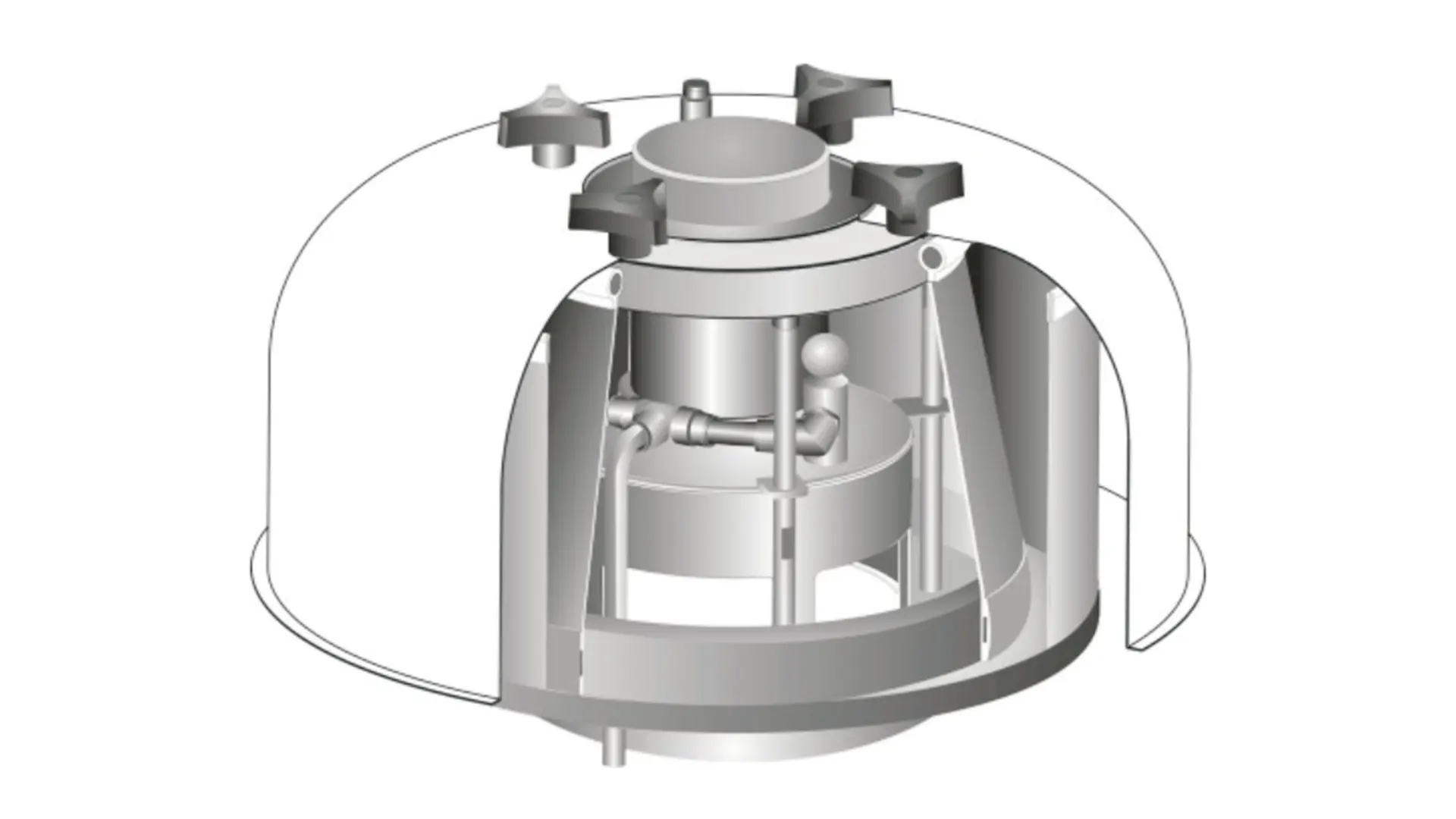

Pressure Vacuum Valve

A patented system for road and rail tankers, providing protection during filling, emptying and transportation.

A patented system for road and rail tankers, providing protection during filling, emptying and transportation.

The PV Valve offers protection against normal volume changes during transportation and routine operation on road and rail tankers. It also provides pressure and vacuum protection for your vessels and tanks during filling and emptying where potential failure situations occur. Additionally, it offers protection from over-filling should an already full tank continue to be filled.

The PV Valve offers a solution to the problem of on-road leakage caused by product surge. This is due to the incorporation of a dwell time in the pressure relief function. The valves are spring to open, air to close, i.e. normally open, to reduce the risk of tank collapses. There is an indicator that is raised when the valve is open as a visual cue to the operational staff.

The PV Valve design has been enhanced by the development of a patented filter kit to EU 5 level that can be retrofitted to existing valves. This allows for the protection of your transported or stored food products, avoiding the possibility of the ingress of contaminated air, especially while in transit.

All PV Valves are able to be fitted with an internal CIP system. Those installations where the CIP header is inside the tank, cleaning is available through the addition of a directional spray ball centrally positioned immediately under the valve. External pipe work is easily connected to the valve via a Teflon tube reducing maintenance costs and improving access for maintenance staff.

Previously known as Mercer Pressure Vacuum Valves.