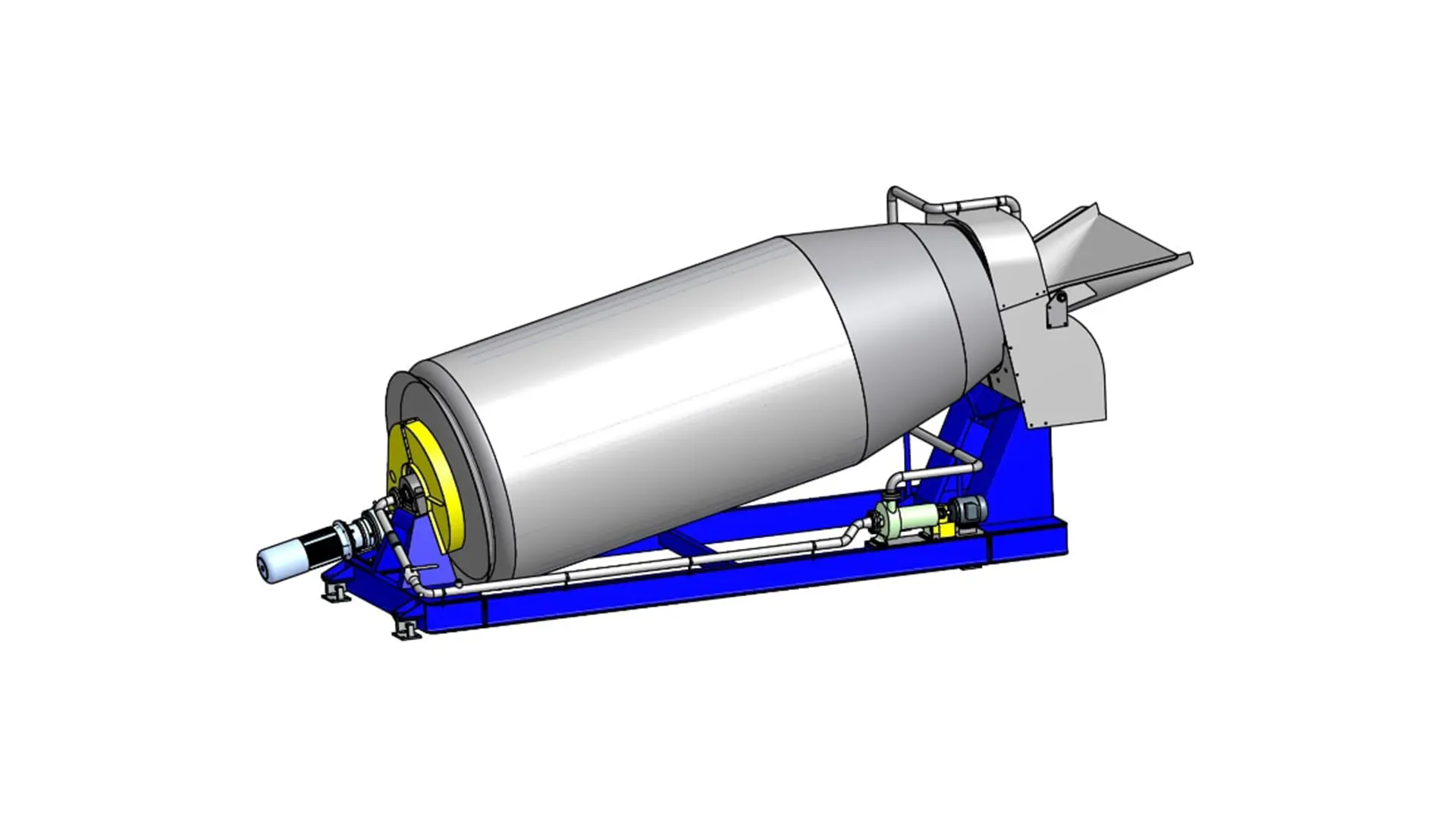

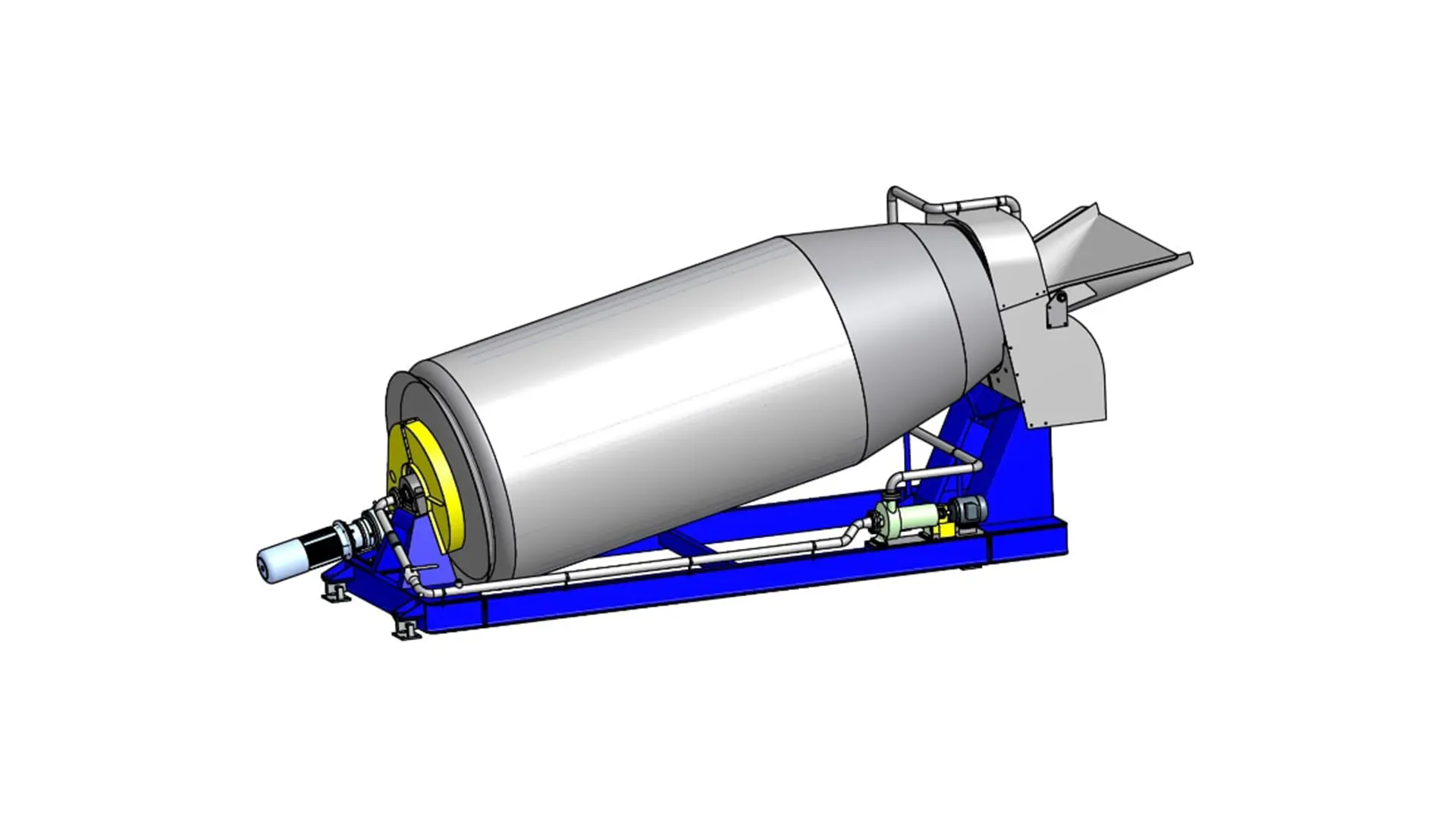

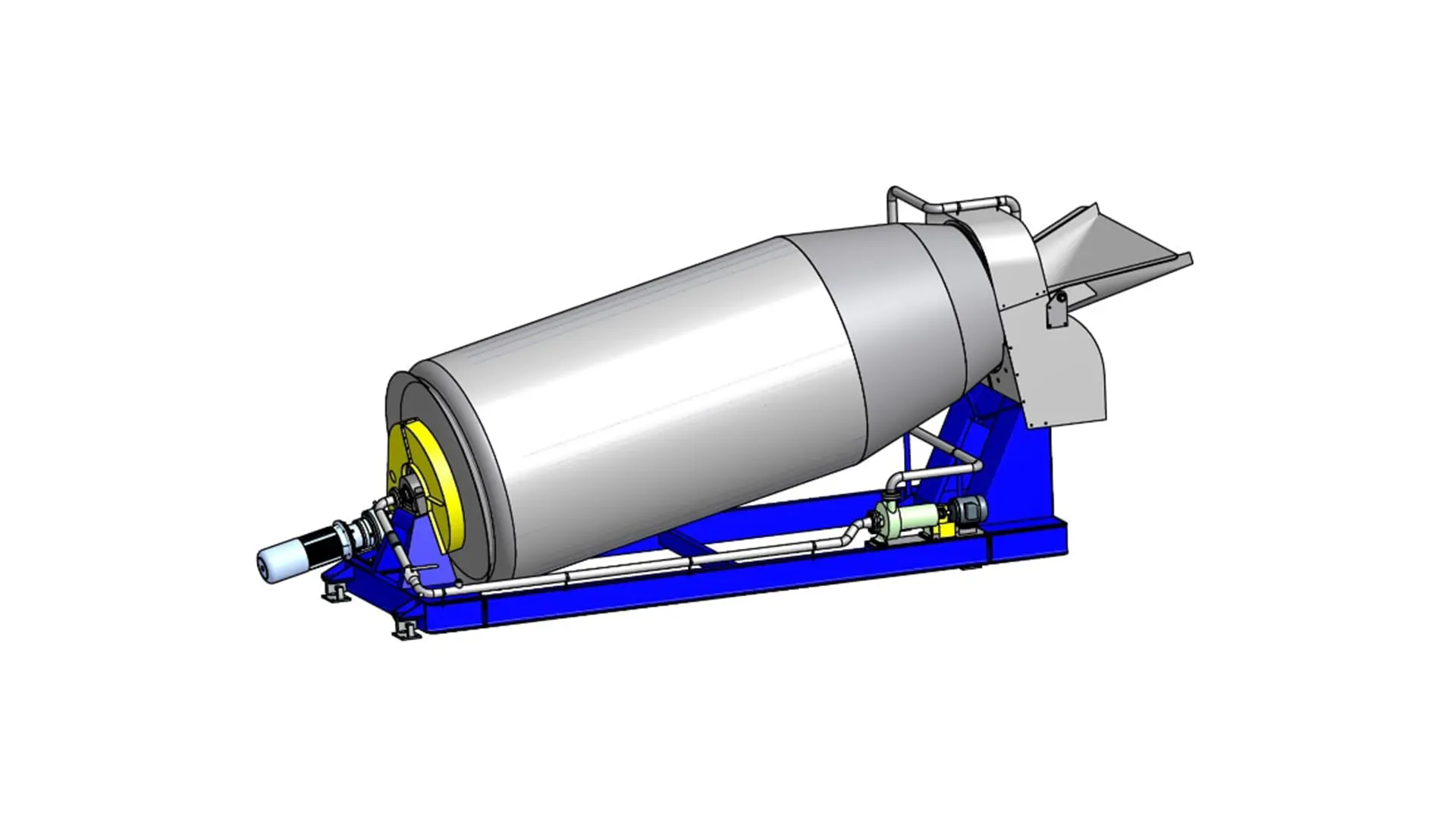

Hide Processor

Complete processing for all animal hide products.

Complete processing for all animal hide products.

All wet operations are undertaken from soaking through tanning to re-tanning, dyeing and fat liquoring plus collagen and gelatin applications of raw stock with either dry salting or brine curing.

The Hide Processor concept is based on an inclined axis mixer principle. In operation its action is gentle yet intensive producing significant benefits

SCE is well-known for its expertise in designing, manufacturing, installing, and servicing equipment within the meat, dairy, grain, timber, and infrastructure sectors across New Zealand and Australia. In 2021, we completed the acquisition of SCE.