SSO Plate Freezers

The world’s largest horizontal plate freezers with a 24-hour freezing capacity of up to 3,017 cartons.

The world’s largest horizontal plate freezers with a 24-hour freezing capacity of up to 3,017 cartons.

Our Plate Freezers feature refrigerant-filled plates which make direct contact with cartons of product to provide a rapid, energy efficient freeze.

Introducing plate freezers on a commercial scale across Australia has saved approximately 15-20% of the energy consumption used for freezing in the meat industry, resulting in a significant reduction in greenhouse gases.

More than 200 plate freezer installations have been completed in Australia to date, and we have the capability to export these to all markets.

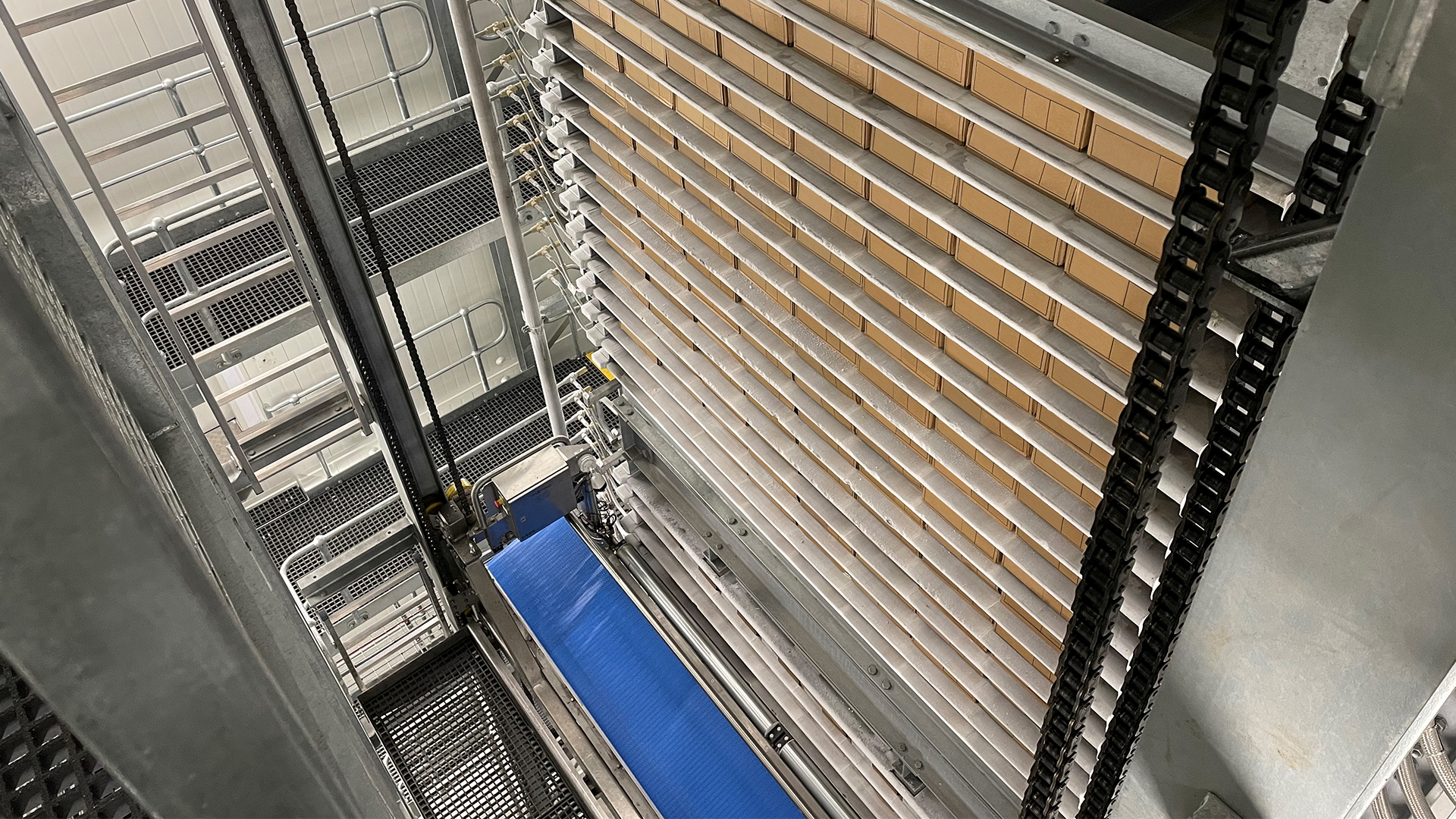

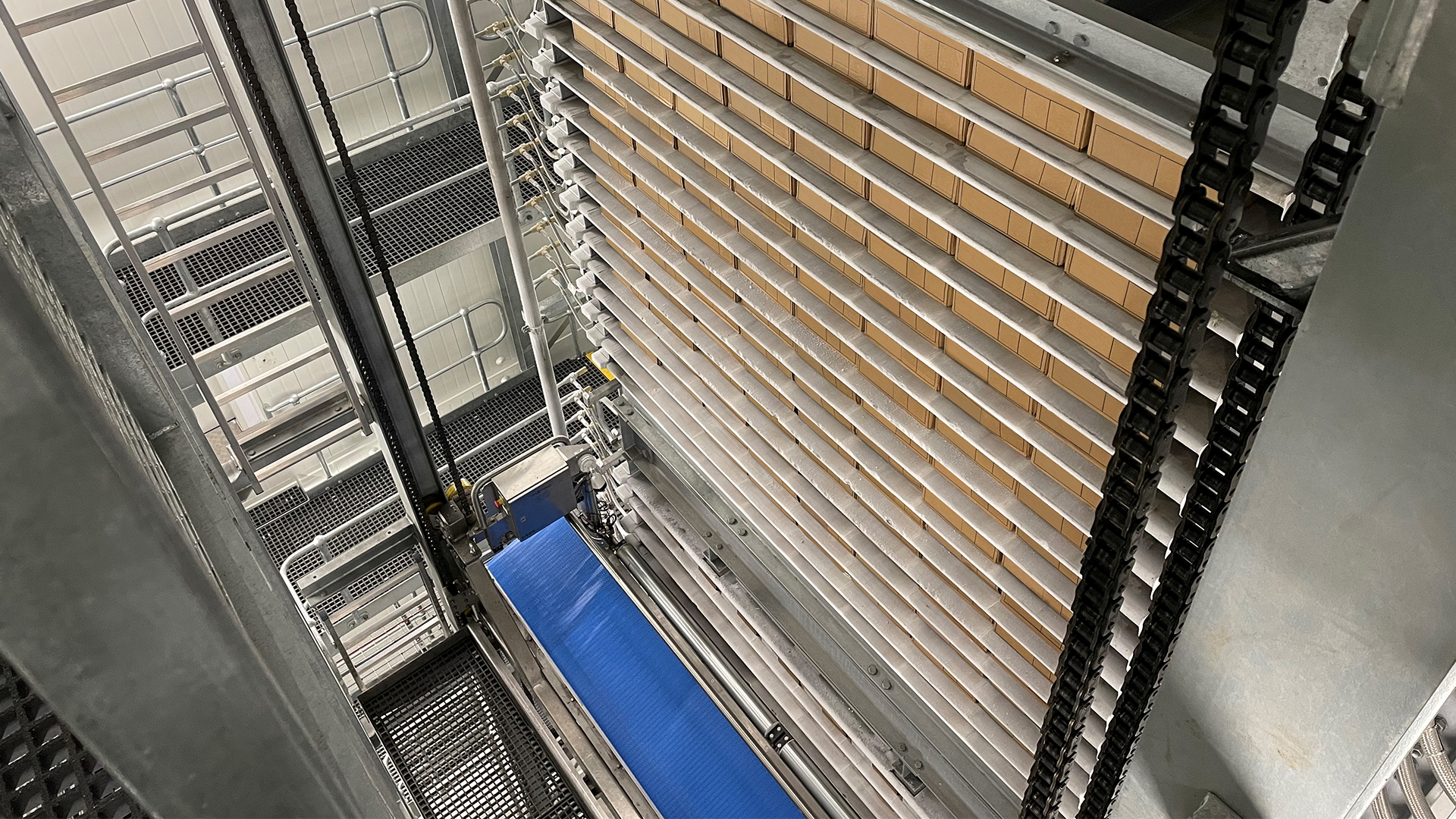

Single station opening (SSO) is our most advanced plate freezer model.

Each station in the plate freezer stack can be opened and closed individually, allowing one station to be open for loading and unloading while the others remain closed to continue the freezing process.

This functionality results in up to 3.5 hours additional contact time with the plates during each cycle, reducing the overall cycle time or allowing for a higher evaporating temperature to further reduce energy consumption.

Products are transferred from the infeed conveyor to the cradle, which elevates and lowers to load cartons into each station. A second elevating cradle is used for unloading frozen cartons, which takes place simultaneously.

Plate freezers are suitable for freezing a range of products, including red meat, pork, poultry and liquid cream, where there is:

SSO plate freezers are particularly suitable for the following applications:

Each plate freezer installation is custom designed to meet the client’s processing requirements. Consideration is given at the design stage to allow flexibility for future additions, extensions and upgrades as product throughput requirements grow.

Plate freezers are available in automatic, semi-automatic or manual configurations, and supplied using ammonia (NH3) as the refrigerant.

Capacity options typically range from 600 to 3,072 standard meat cartons, or 16 to 84 tonnes of product.

Milmeq, whose automated chilling and freezing systems have established the global benchmark for cooling and freezing meat, poultry and dairy products in cartons or crates, were acquired by MHM Automation in 2018.