SSO LAMB PLATE FREEZERS

Three Milmeq SSO Plate Freezers have been installed at Fletcher International Exports’ Dubbo plant as part of a long term project to expand their chilling and freezing capacity and ensure regulatory compliance.

Three Milmeq SSO Plate Freezers have been installed at Fletcher International Exports’ Dubbo plant as part of a long term project to expand their chilling and freezing capacity and ensure regulatory compliance.

Fletcher

Fletcher

Fletcher International Exports is one of Australia’s most integrated processors and exporters of lamb and sheep meat products, exporting to over 90 countries around the globe.

They operate two processing facilities, one located in Dubbo, New South Wales, and the other near Albany, Western Australia.

Fletcher sought to increase the freezing capacity and improve product quality at their Dubbo plant. Initially this involved converting from air blast freezing to plate freezing. Subsequently, additional plate freezers were required to allow for further increases in plant throughput.

Key objectives included:

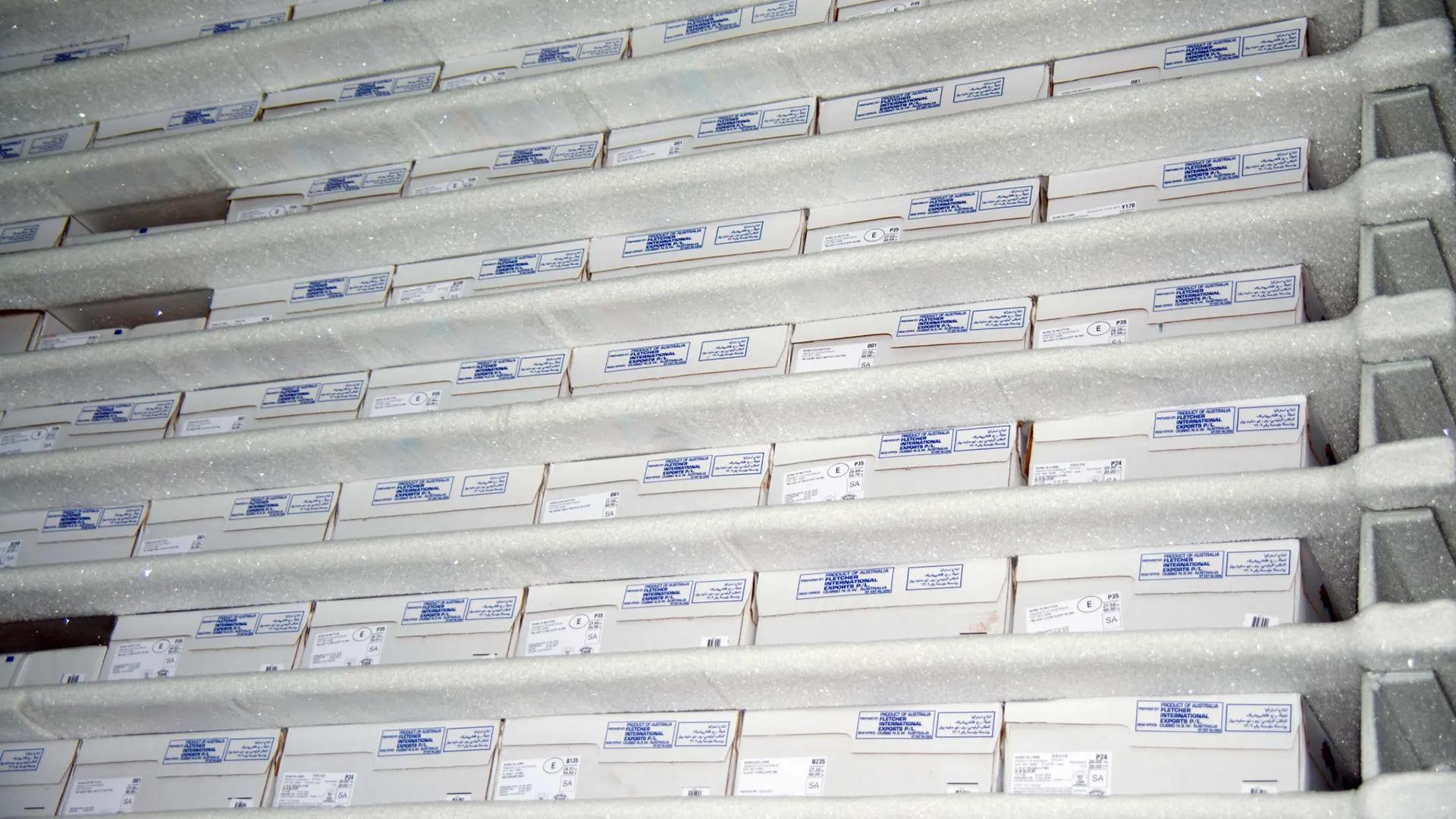

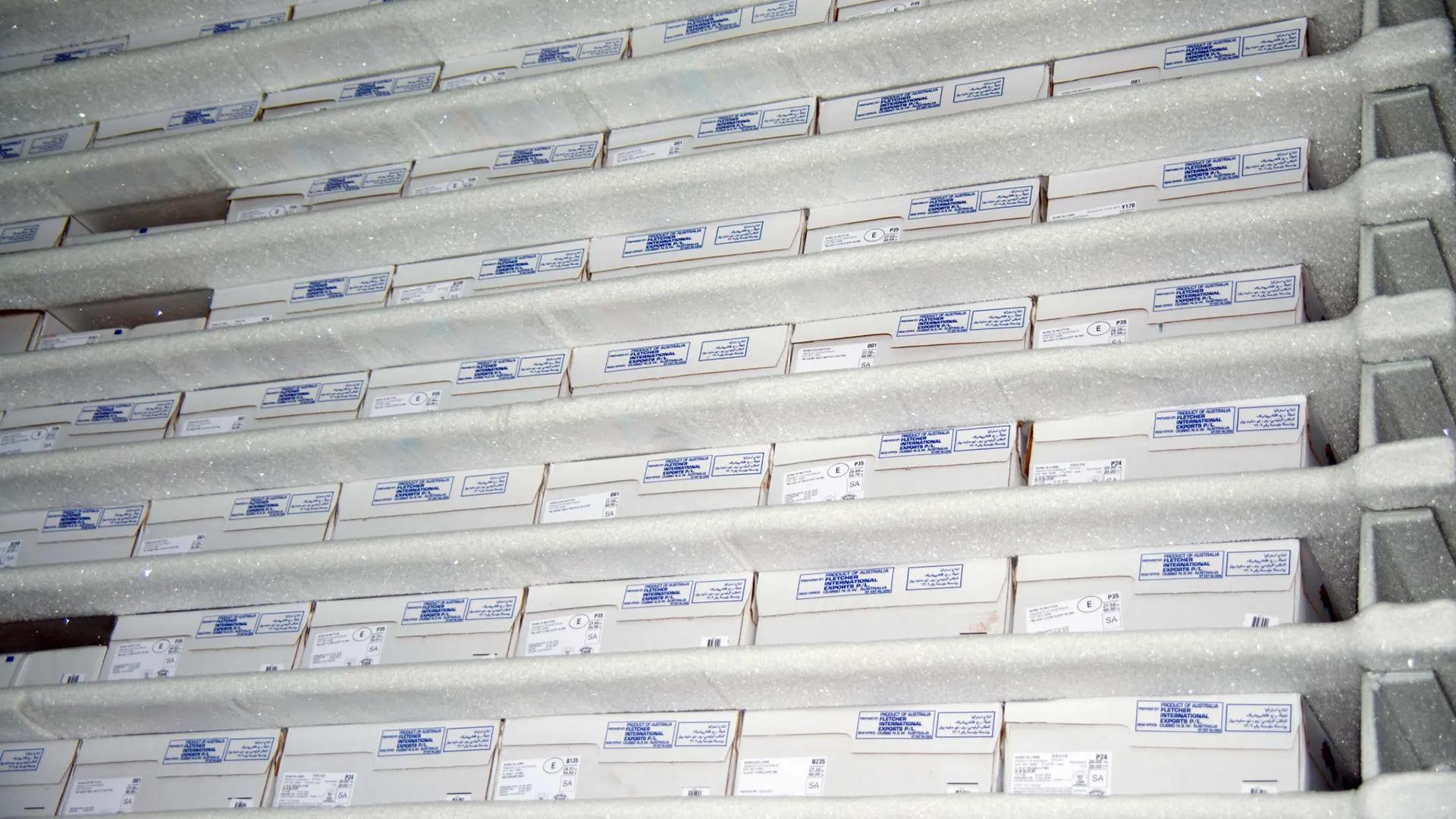

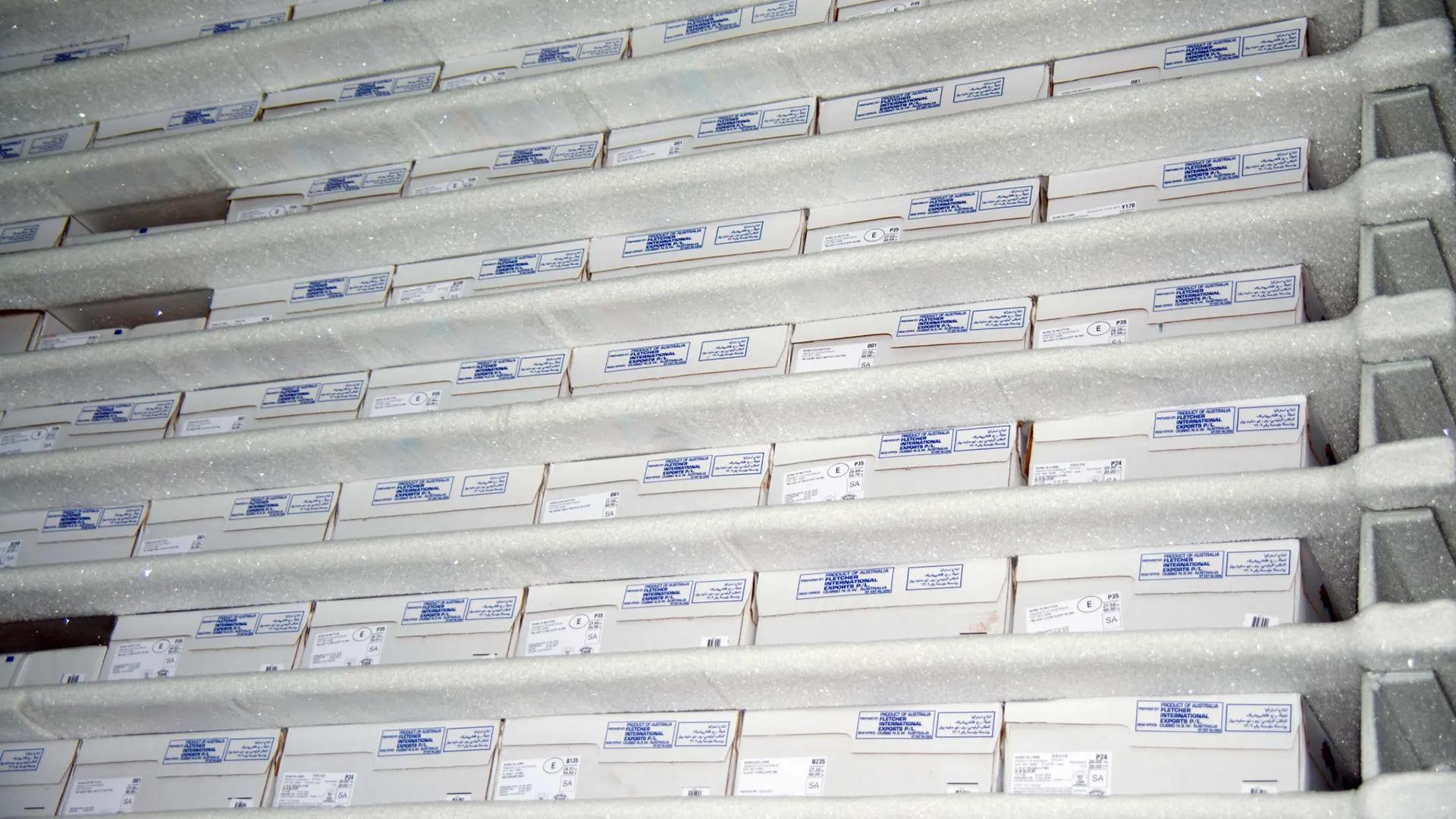

In 2015, three Milmeq horizontal plate freezers were commissioned at Fletcher’s Dubbo plant, each with the capacity to freeze 2,300 cartons in a 24 hour cycle.

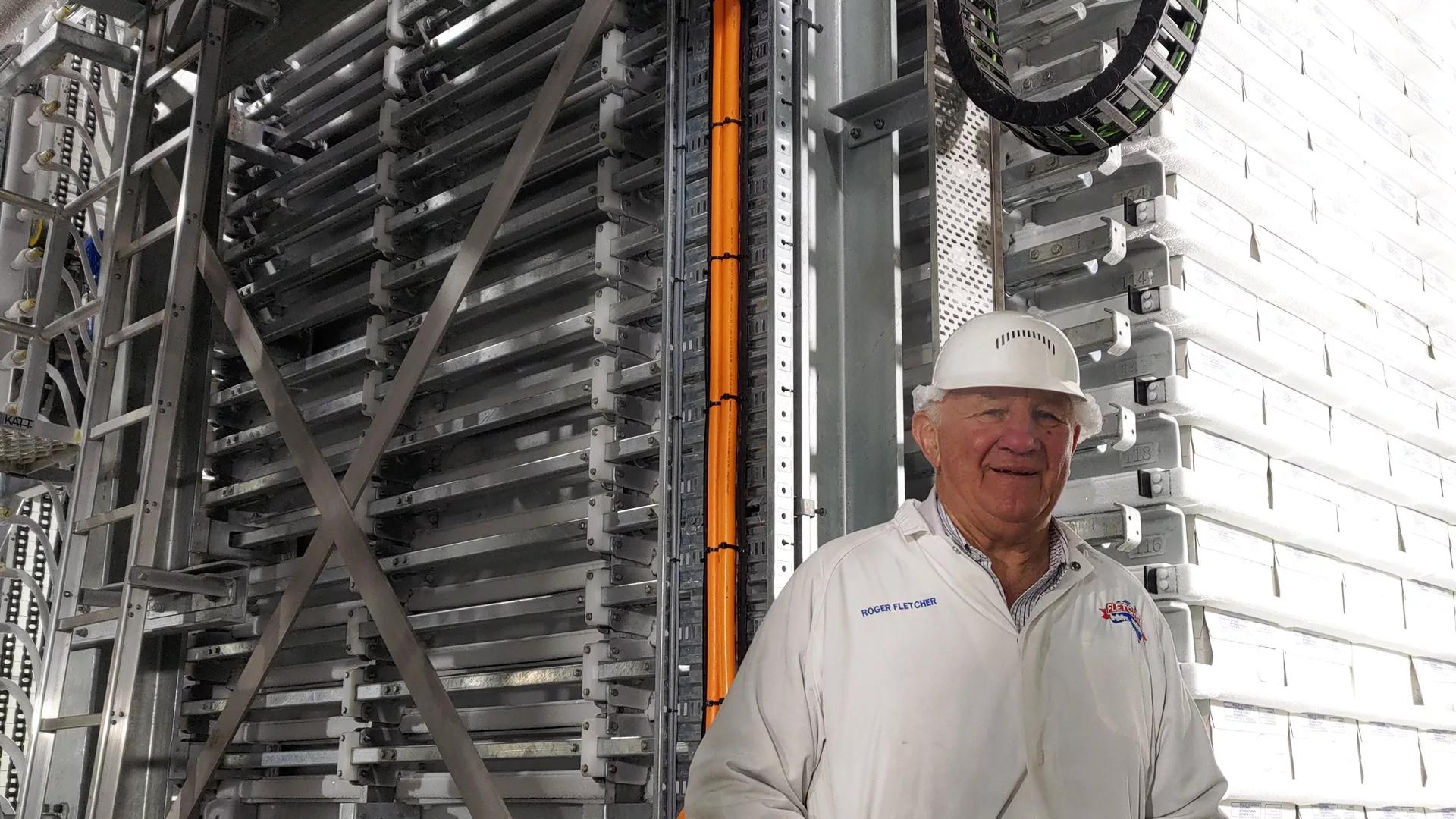

The third of these featured a new technology innovation, single station opening (SSO), which was developed in partnership with Fletcher to meet their requirements to reduce the temperature of their hot boned products as quickly as possible. This was the first commercial prototype of the SSO model of Milmeq plate freezer.

On the SSO model, only one level (or station) of plates opens at a time for loading cartons, rather than all levels opening at once. This means cartons are under contact with both plates sooner and provides three hours additional freezing time per day.

In 2021, MHM Automation installed two additional SSO plate freezers, each standing at 12 metres high, with a capacity of 2,560 cartons. This installation was a milestone as it included the 200th Milmeq plate freezer to be installed in Australia.

Freezing in plate freezers more than halves the time required to freeze cartons of meat, which results in better shelf life for the export meat products. The SSO design increases the effective refrigeration, to ensure regulatory compliance.

Milmeq plate freezers are a key contributor to reducing the plant’s electrical energy consumption, delivering savings of up to 30% over the blast freezing method traditionally used.

Another significant advantage Fletcher has seen since moving from blast freezing to plate freezing their product is the production of completely flat cartons. This allows 10% more cartons to be stacked into each 20-foot shipping container, effectively reducing shipping costs.

Completely automated loading and unloading operation, with integrated infeed and outfeed conveyors, reduces the plant’s reliance on manual labour as well as the health and safety risks associated with manual handling and working in a frozen environment.