Meat freezing tunnel - AFFCO

The tunnel was installed and commissioned in early 2023, effectively replacing the oldest of the existing tunnels on the site.

The tunnel was installed and commissioned in early 2023, effectively replacing the oldest of the existing tunnels on the site.

Affco

Affco

AFFCO is a leading New Zealand lamb and beef processor, with 12 processing plants across the country and exporting to more than 80 countries worldwide.

As part of a programme of ongoing modernisation and expansion of its Wairoa plant, AFFCO sought to replace some of the sites existing blasts with newer models. The desired outcomes included increased freezing capacity and improvements in reliability, product consistency and worker safety.

The original tunnels installed at the plant had been operating reliably for over 60 years but were now not delivering enough freezing capacity. They were also no longer compliant with current safety standards.

A variety of products were required to be frozen in the tunnels, including hot-boned beef, cold-boned beef, cold-boned lamb and offal, in cartons varying in size from 20-34kg.

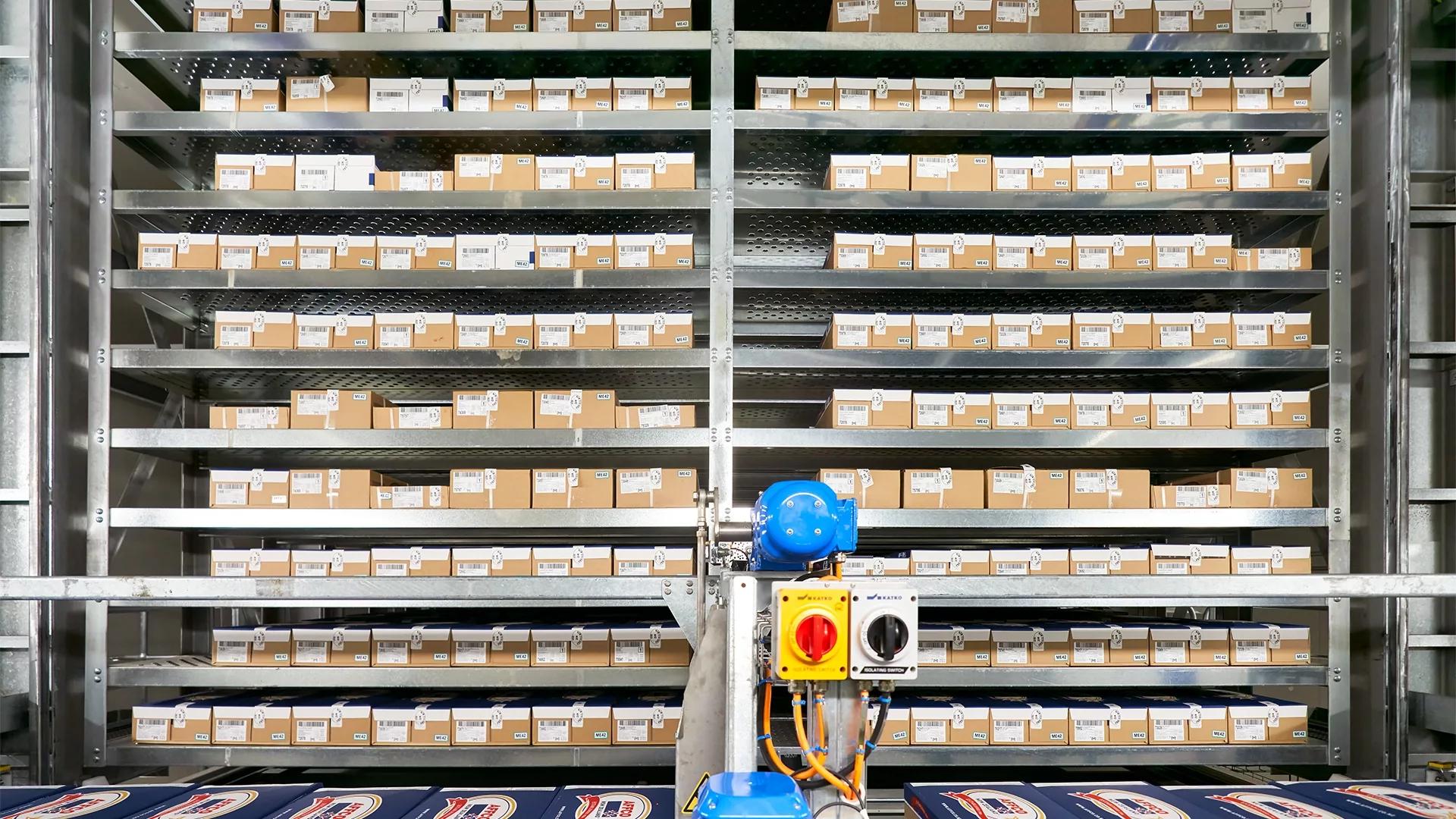

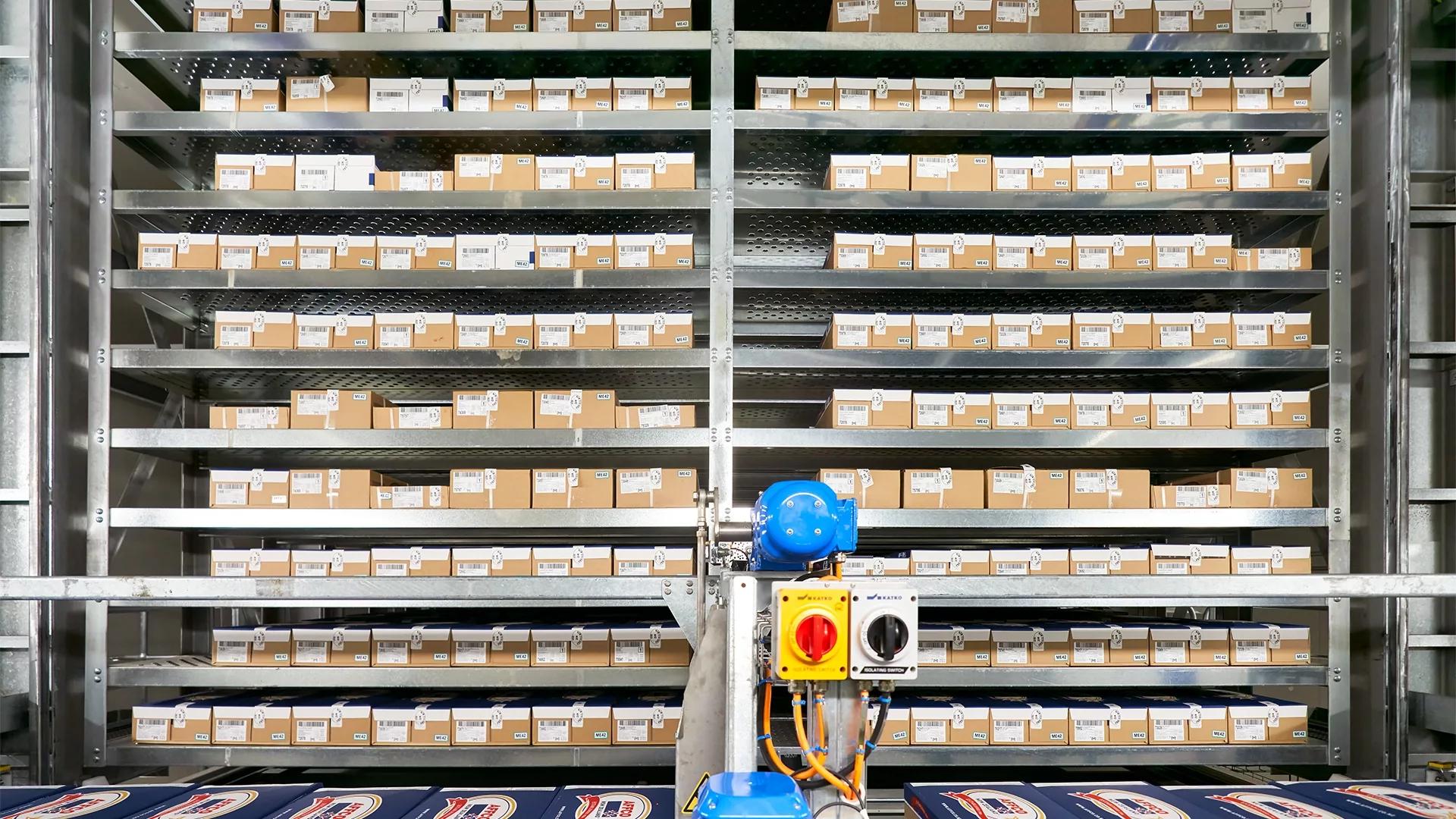

We provided a Milmeq Single Retention Time (SRT) Meat Freezing Tunnel with capacity to freeze 13,104 cartons in a 48-hour cycle, allowing a daily throughput of approximately 6,500 large cartons.

The tunnel has a cross-flow design and utilises ammonia as the coolant to provide an air temperature of -32°C to freeze the product in the required 48-hour timeframe.

The tunnel operation is completely automated, with infeed conveyors spacing and loading product into the tunnel and outfeed conveyors unloading product into the plant sortation system.

Wairoa is a medium seismic zone, so the tunnel was custom designed with additional bracing to ensure safety if an earthquake was to strike.

The tunnel was installed and commissioned in early 2023, effectively replacing the oldest of the existing tunnels on the site.

It is operating reliably and delivering better consistency of product quality and throughput than the old tunnels. As a result, the client has found they are able to process more cartons than the originally intended capacity. With the tunnel now in place, AFFCO can focus on optimising the rest of the plant to expand its daily throughput.