Lidder, Plate Freezers, ASRS and Robotic Palletising

An integrated solution to automate all processes from boning room to palletising, handling both chilled and frozen meat products.

An integrated solution to automate all processes from boning room to palletising, handling both chilled and frozen meat products.

The Midfield Group

The Midfield Group

The Midfield Group is a major player in the Australian meat processing market. They have a large sheep and beef processing facility in Warrnambool, VIC.

Midfield has had a long relationship with MHM Automation’s legacy companies, with 13 Milmeq plate freezers and several AiCo carton lidders and compactors previously supplied and installed at the plant.

Midfield wanted to automate the back end of their production processes, including chilling, freezing, sorting and palletising.

Their goals included freeing up space for further processing expansion, reducing reliance on manpower, effectively managing inventory for production and sales, and reducing energy consumption.

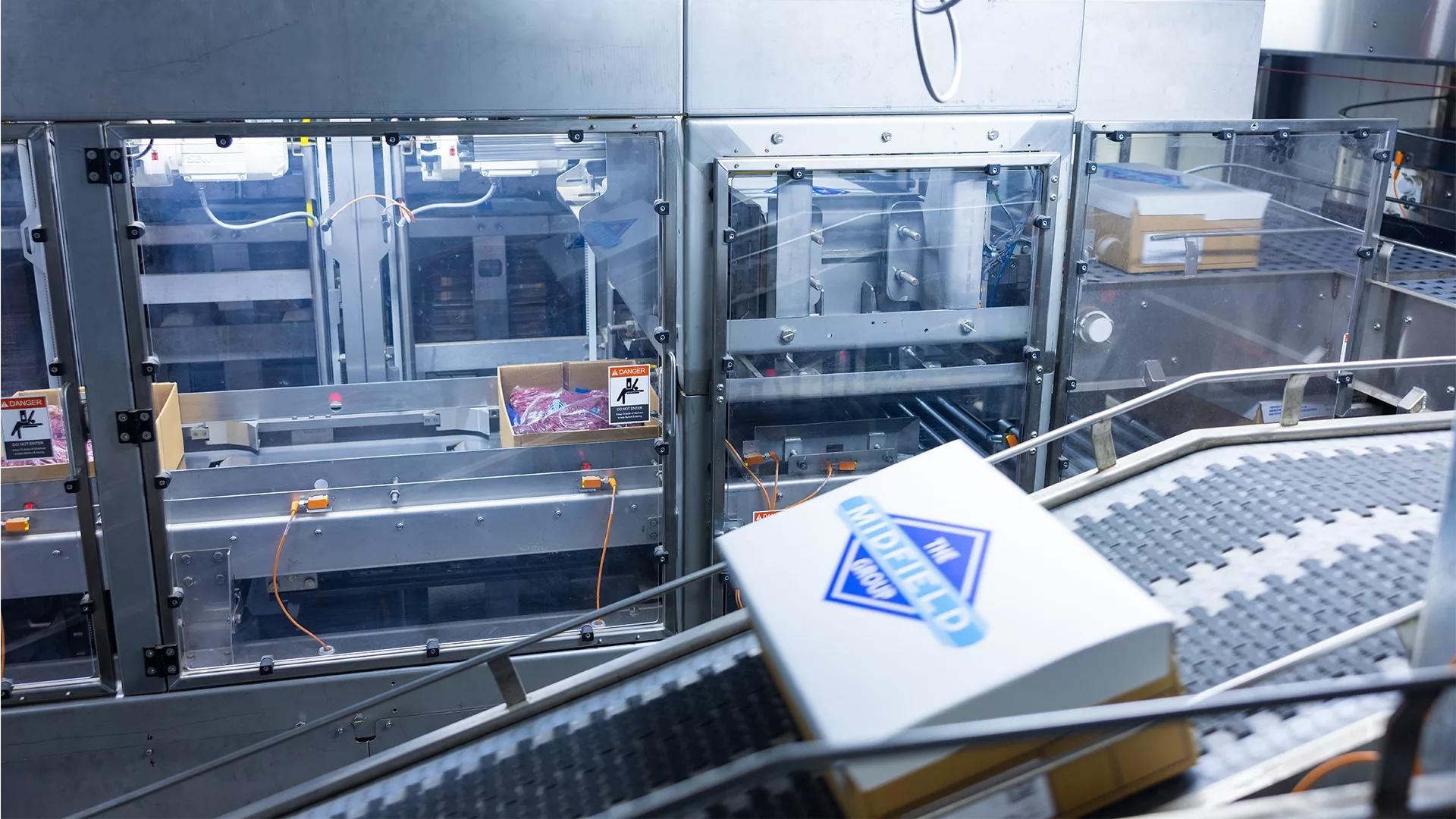

MHM Automation was contracted to supply several systems to effectively automate all processes after the product is boxed and barcoded. This included:

The Lidder and Plate Freezers were commissioned in 2021, expanding the total freezing capacity of the plant to approximately 25,000 cartons per day. The benefits of plate freezing include guaranteed freezing profiles and flat cartons, which allow reliable use of ASRS and automated palletising.

The three-cell palletising system was installed in 2022. As well as reducing labour requirements and the health and safety risks posed by manual handling, this system automates the pallet scanning and Meat Messaging label generation, removing the need to manually port mark every carton.

The ASRS installation was completed in May 2023, with it being our first ASRS installation together with technology partners TGW and Inther.