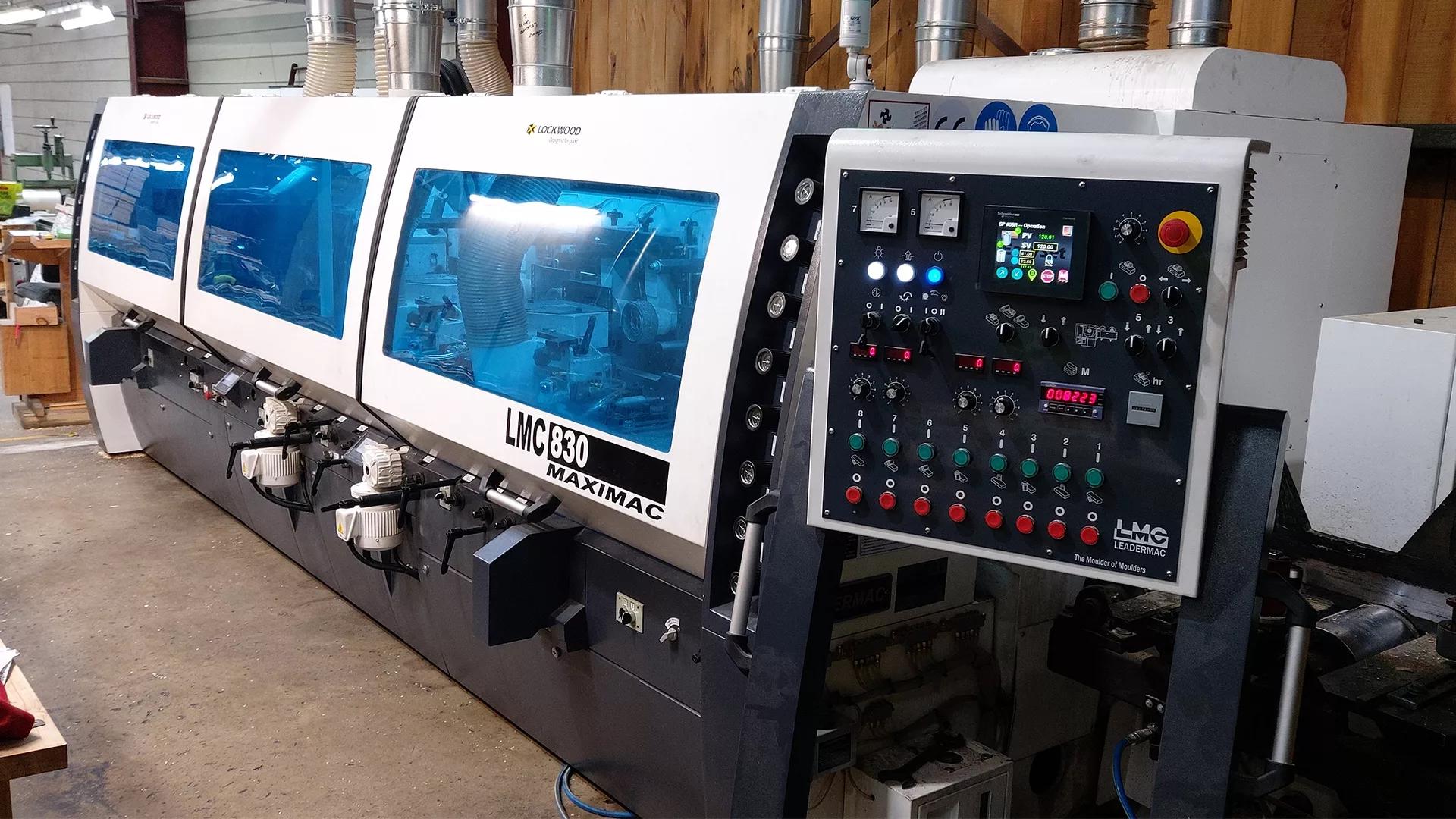

Planer/moulder & grinder

A complex and difficult installation resulted in a robust, high-performance system that reliably finishes timber planks within tight tolerances.

A complex and difficult installation resulted in a robust, high-performance system that reliably finishes timber planks within tight tolerances.

Lockwood Homes

Lockwood Homes

Lockwood Group has been building high-performance homes from locally-sourced forestry timber for more than 70 years.

Its unique building system features solid laminated timber planks, which lock together to form the exterior and interior walls of the structure.

To meet growing demand for new homes, Lockwood Group sought to upgrade their production facility in Rotorua.

Their planning, moulding and grinding requirements were complex, with specific, intricate profiles needing to be produced.

Following close consultation with the client to understand their specific requirements, MHM Automation provided:

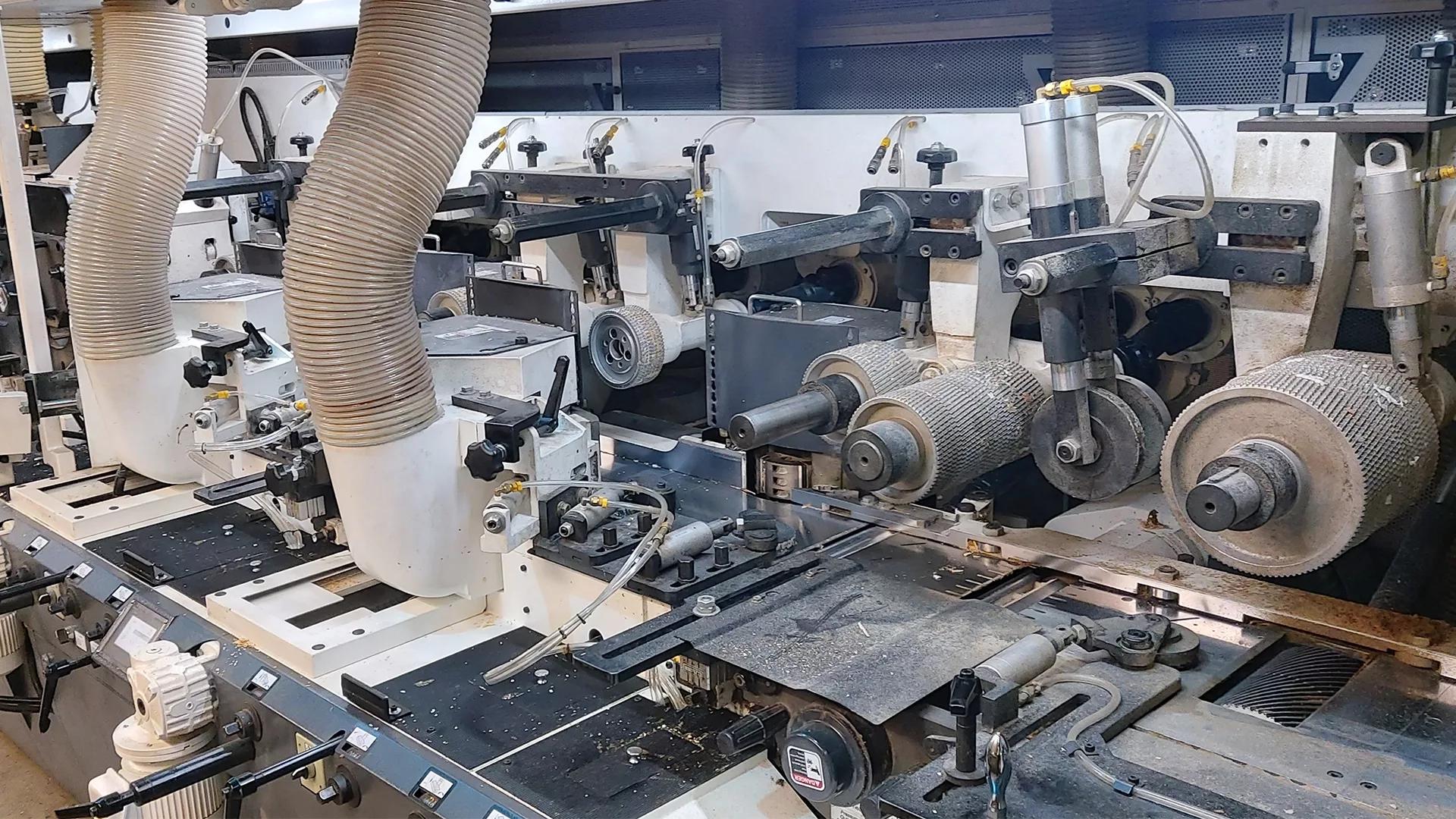

The eight spindle Leadermac Maximac configuration was specifically chosen to create Lockwood Group’s intricate profiles. Servo straight jointers were fitted to spindles 1, 6, 7 and 8, and profile jointers were fitted to spindles 4, 5, 7 and 8.

The added feature of variable speed controllers allows operators to increase the spindle RPM to obtain the desired finish at an increased feed speed when a shorter run doesn’t lend itself to jointing.

The Maximac design originated in New Zealand, to meet the local industry’s need for a dedicated, heavy duty 300mm wide machine. It has an impressive list of standard features, including:

A complex and difficult installation resulted in a robust, high-performance system that reliably finishes timber planks within tight tolerances.

It has significantly increased capacity at the Lockwood Group production facility, as well as aiding in creating a smooth construction process for Lockwood homes.