Partnership delivers 200th Milmeq plate freezer installation

A milestone installation is the result of an enduring partnership between two future-focused companies in the Australian meat industry.

A milestone installation is the result of an enduring partnership between two future-focused companies in the Australian meat industry.

MHM Automation has recently commissioned the 200th Milmeq plate freezer at Fletcher International Exports’ sheep meat processing plant in Dubbo, NSW.

MHM Automation Sales Manager – Australia, Chris Carter, said the project was the result of a longstanding relationship between the companies.

“Fletcher International Exports has always been an innovator in the meat industry. They’re constantly looking to new technology to improve the quality of their product and the performance of their business, and we’re proud to work with them to develop and deliver industry-leading equipment.

“It’s fitting that this milestone installation is for Fletchers,” he said.

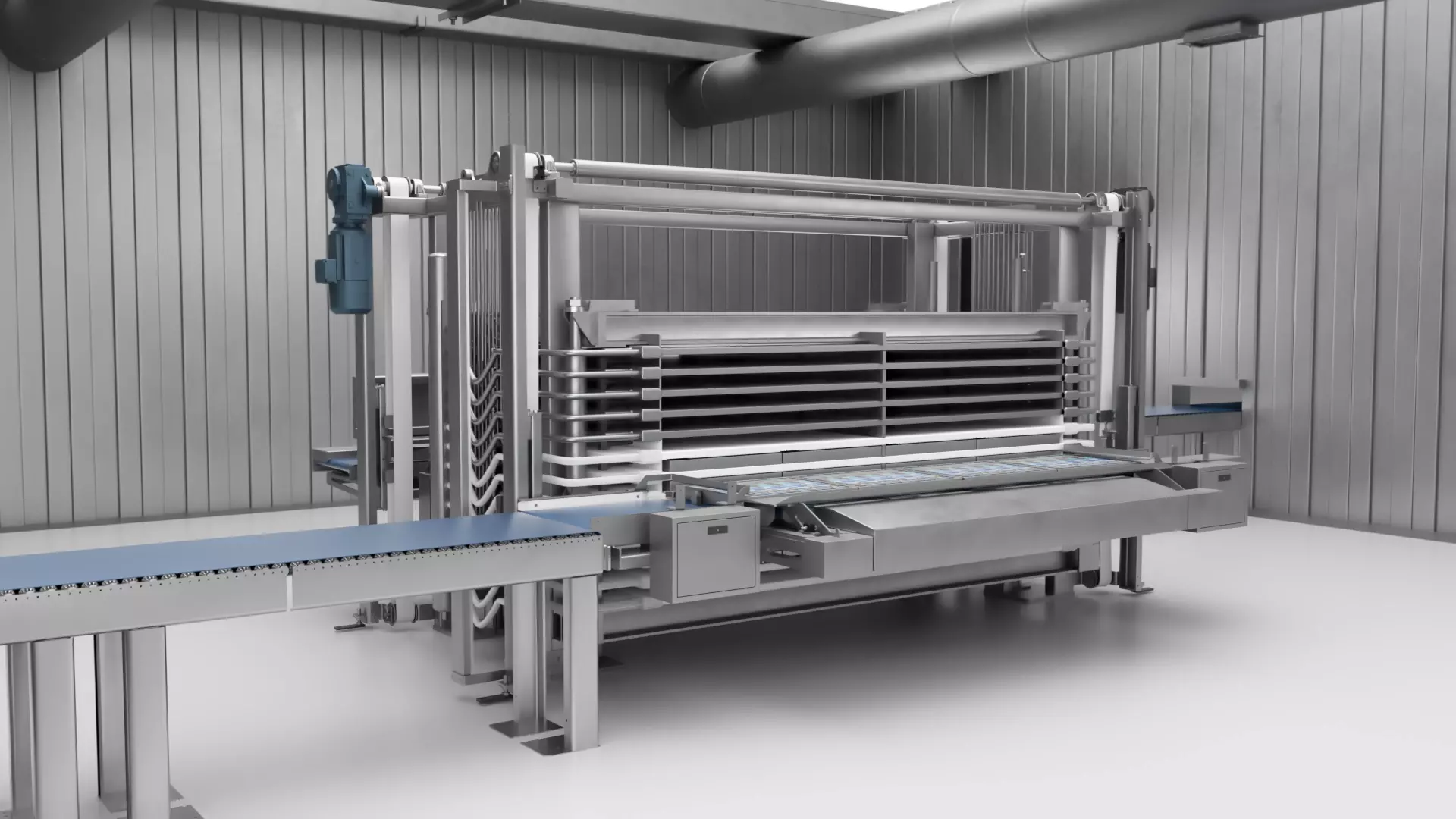

The development and provision of plate freezers to the meat industry was led by Milmeq in the 1990s. Today Milmeq plate freezers are the largest horizontal plate freezers in the world and continue to be the fastest and most energy efficient system for freezing cartons of meat.

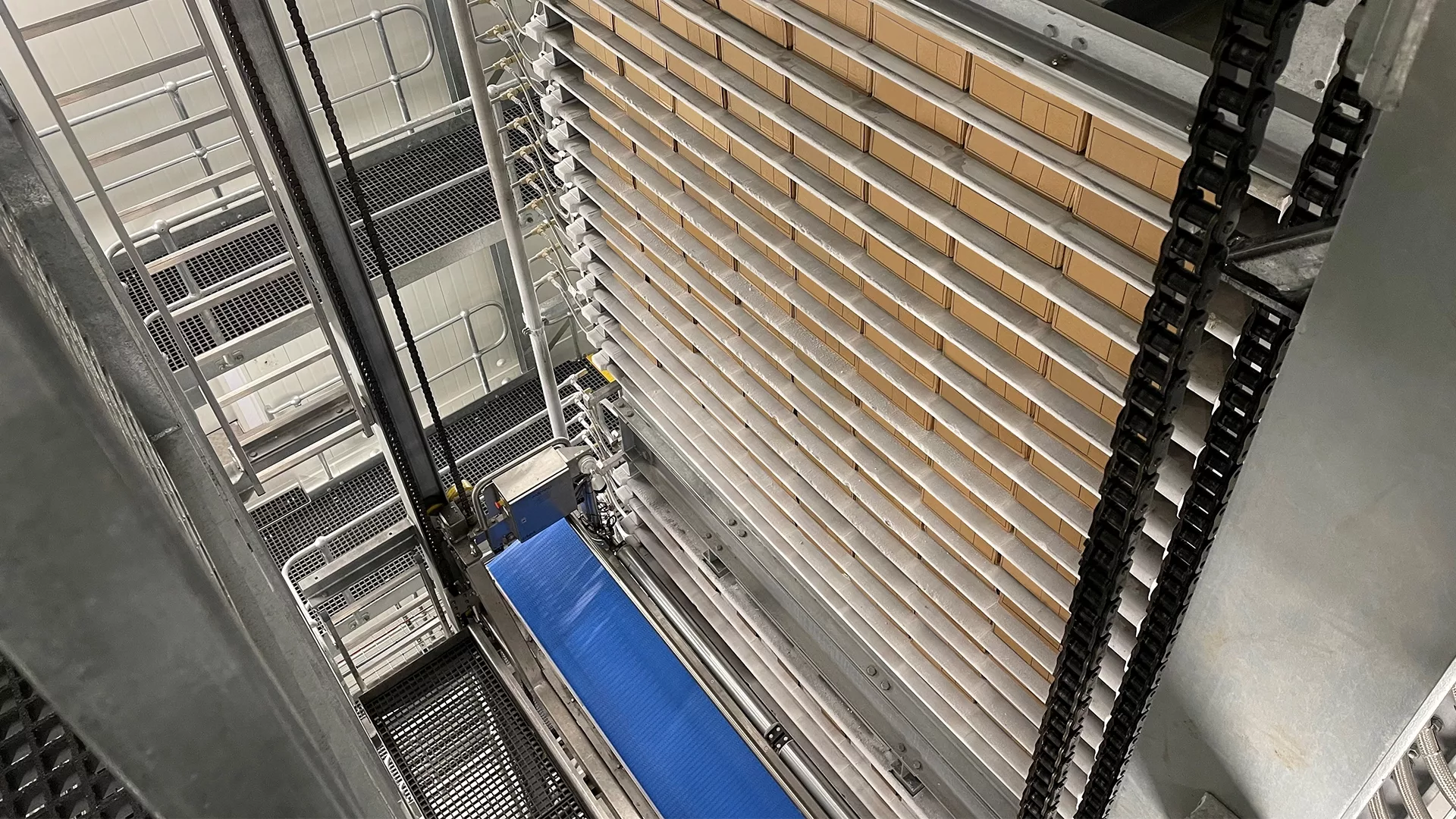

The latest project saw the installation of two new plate freezers at Fletcher International Exports’ Dubbo plant, each standing at 12 metres high, with a capacity of 2,560 cartons and the ability to completely freeze cartons of cold boned product in less than 24 hours.

The new installations bring the total number of Milmeq plate freezers installed for Fletcher International Exports across both its plants to eighteen, three of which feature the latest technology innovation, single station opening (SSO).

The SSO plate freezer model was a collaborative development between Milmeq (now part of MHM Automation) and Fletcher International Exports, with the first commercial prototype being commissioned at Fletcher’s Dubbo processing site in 2015.

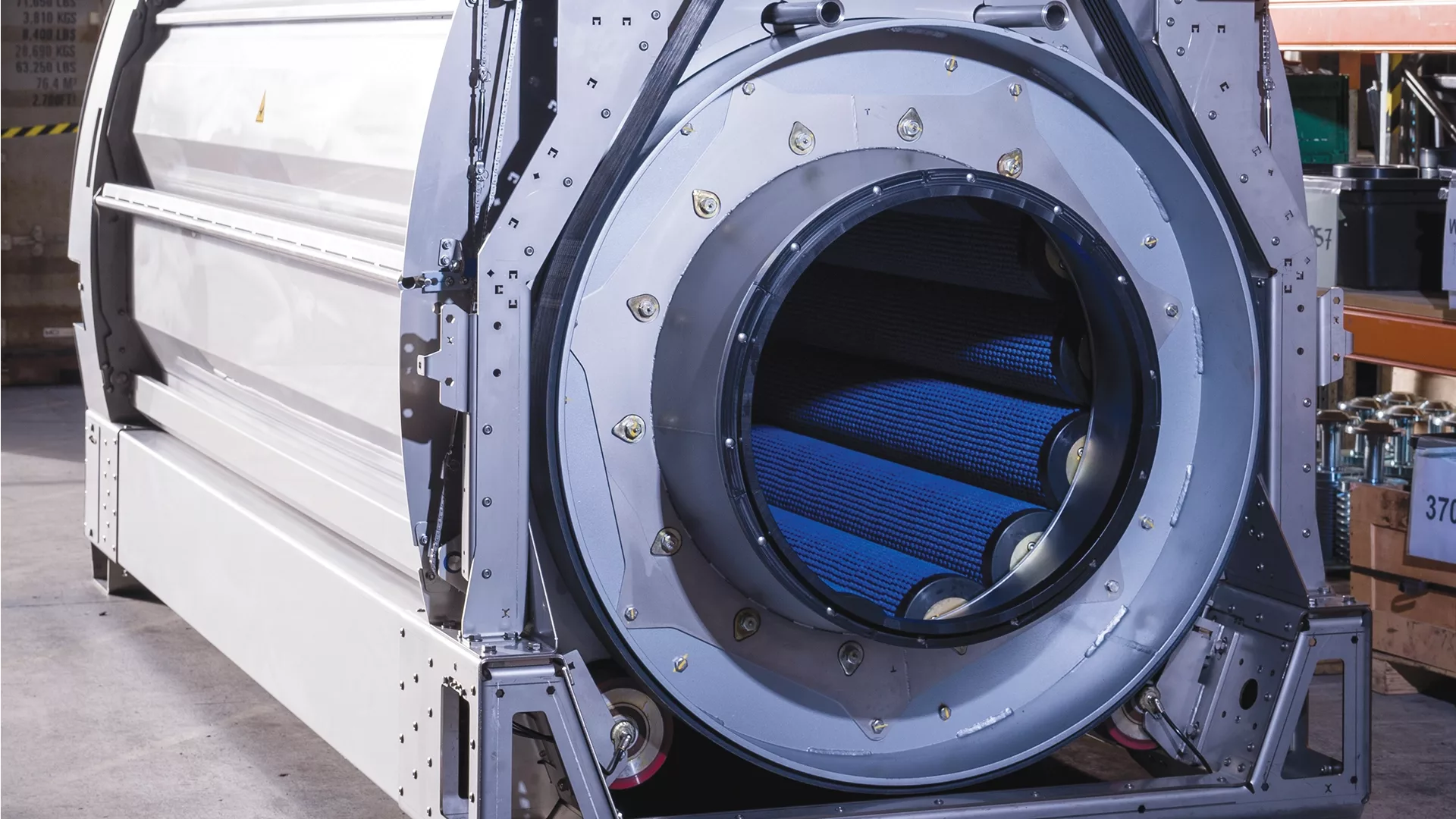

The SSO mechanism allows products to be automatically loaded and unloaded one station at a time, keeping the remaining stations closed and product in those stations in contact with the plates to continue the freezing process. The SSO design increases the effective refrigeration, to ensure regulatory compliance.

Fletcher International Exports owner, Roger Fletcher said the technology delivered by MHM Automation was second to none.

“The MHM Automation team share our pioneering spirit and have worked closely with us to help scale-up our operations and cement our reputation as an industry leader. Their plate freezers are enabling us to deliver a superior product to our customers, while also reducing our environmental footprint,” he said.

Milmeq plate freezers are a key contributor to reducing the plant’s electrical energy consumption, delivering savings of up to 30% over the blast freezing method traditionally used. Freezing in plate freezers more than halves the time required to freeze cartons of meat, which results in better shelf life for the export meat products.

Cartons frozen in the plate freezers have completely flat presentation, allowing 10% more cartons to be stacked into each 20-foot shipping container, effectively reducing shipping costs.

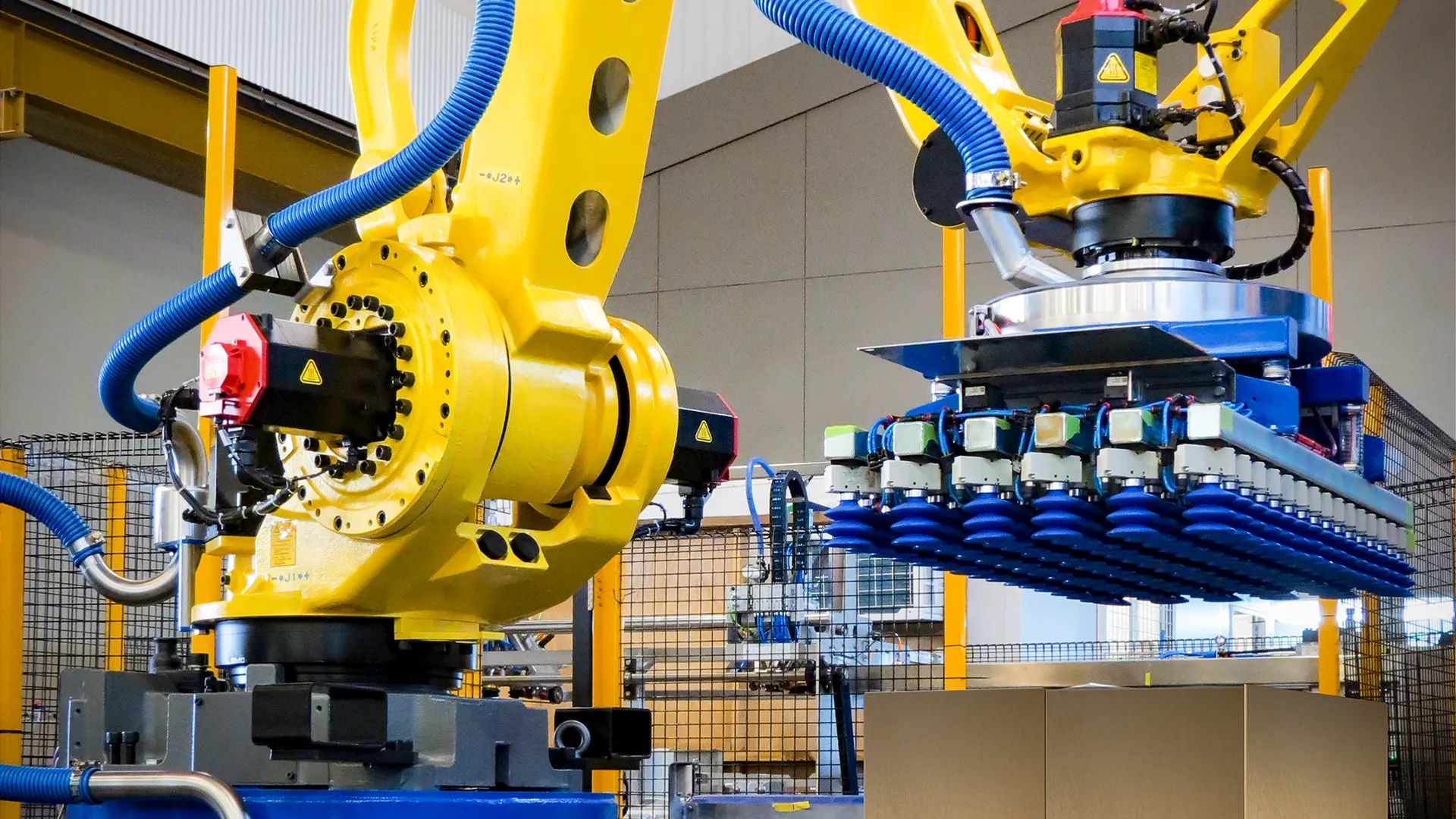

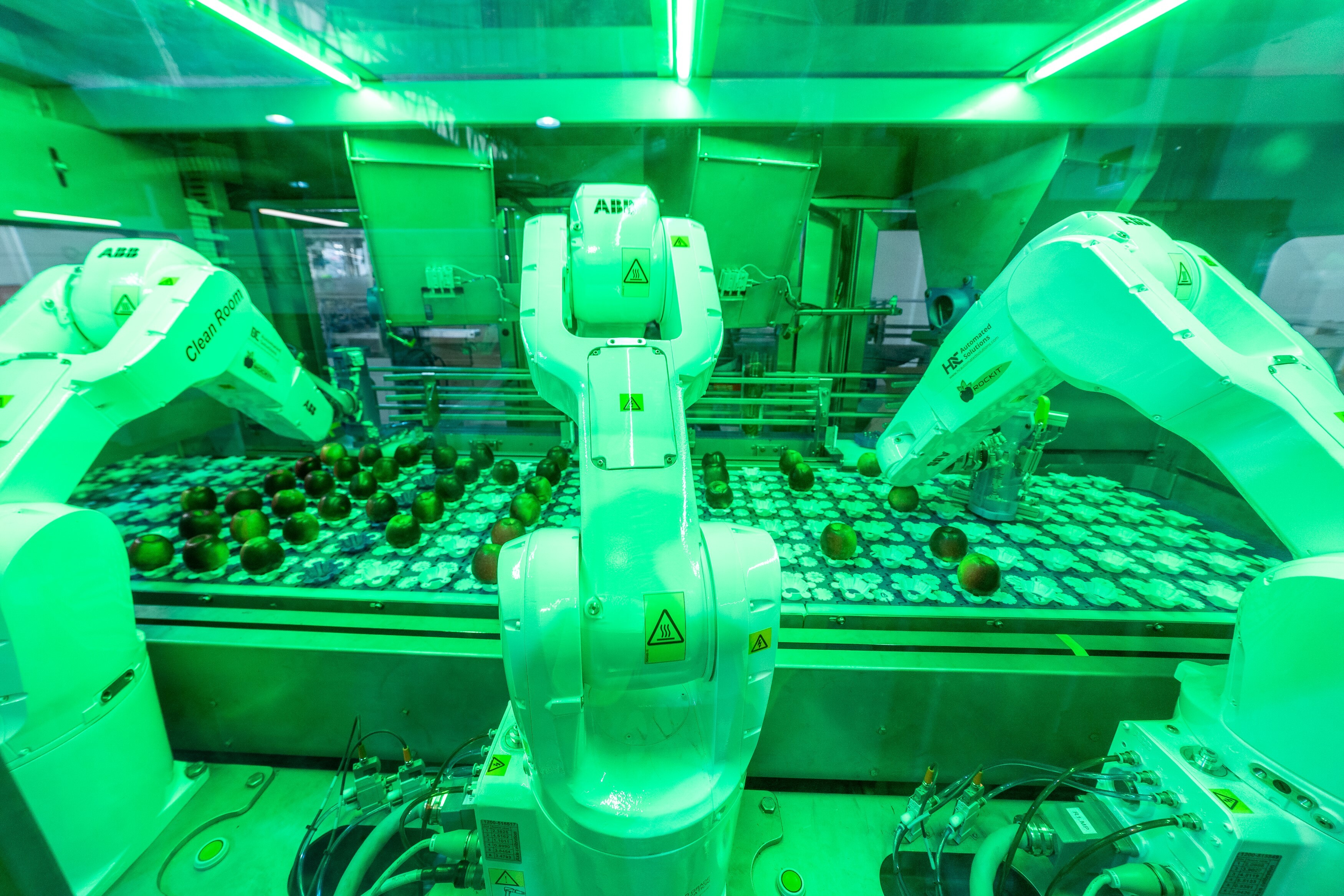

Completely automated loading and unloading operation, with integrated infeed and outfeed conveyors, reduces the plant’s reliance on manual labour as well as the health and safety risks associated with manual handling and working in a frozen environment.

18 November 2025

18 November 2025

13 June 2025

10 April 2025

14 January 2025

07 March 2024

03 November 2023

03 October 2023

27 July 2023

23 May 2023

02 May 2023

15 March 2023

28 February 2023

14 February 2023

10 February 2023

09 February 2023

27 January 2023

18 January 2023

05 December 2022

03 November 2022

28 October 2022

04 October 2022

25 August 2022

08 September 2021

27 August 2021

14 June 2021

16 December 2020

25 August 2020