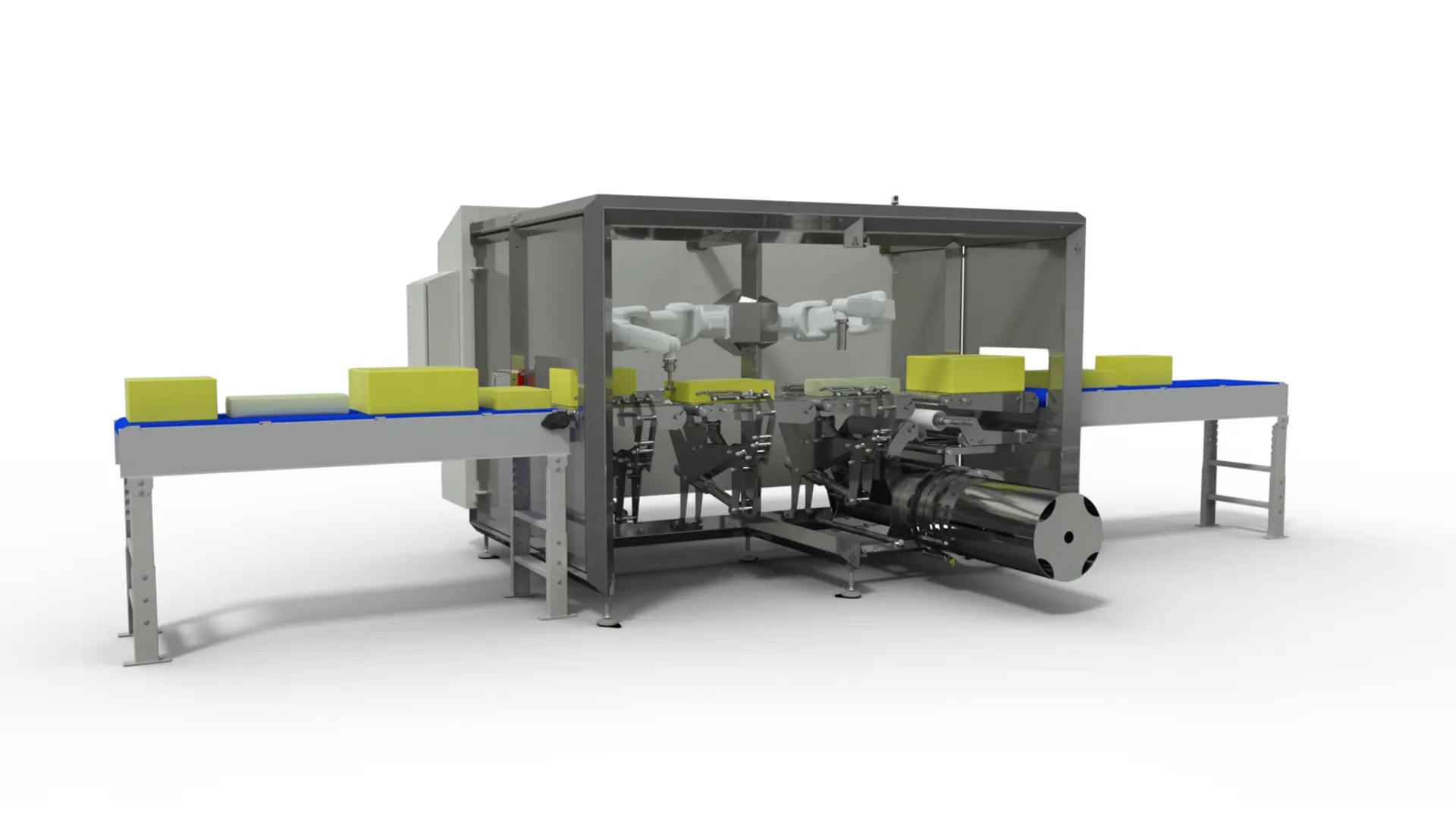

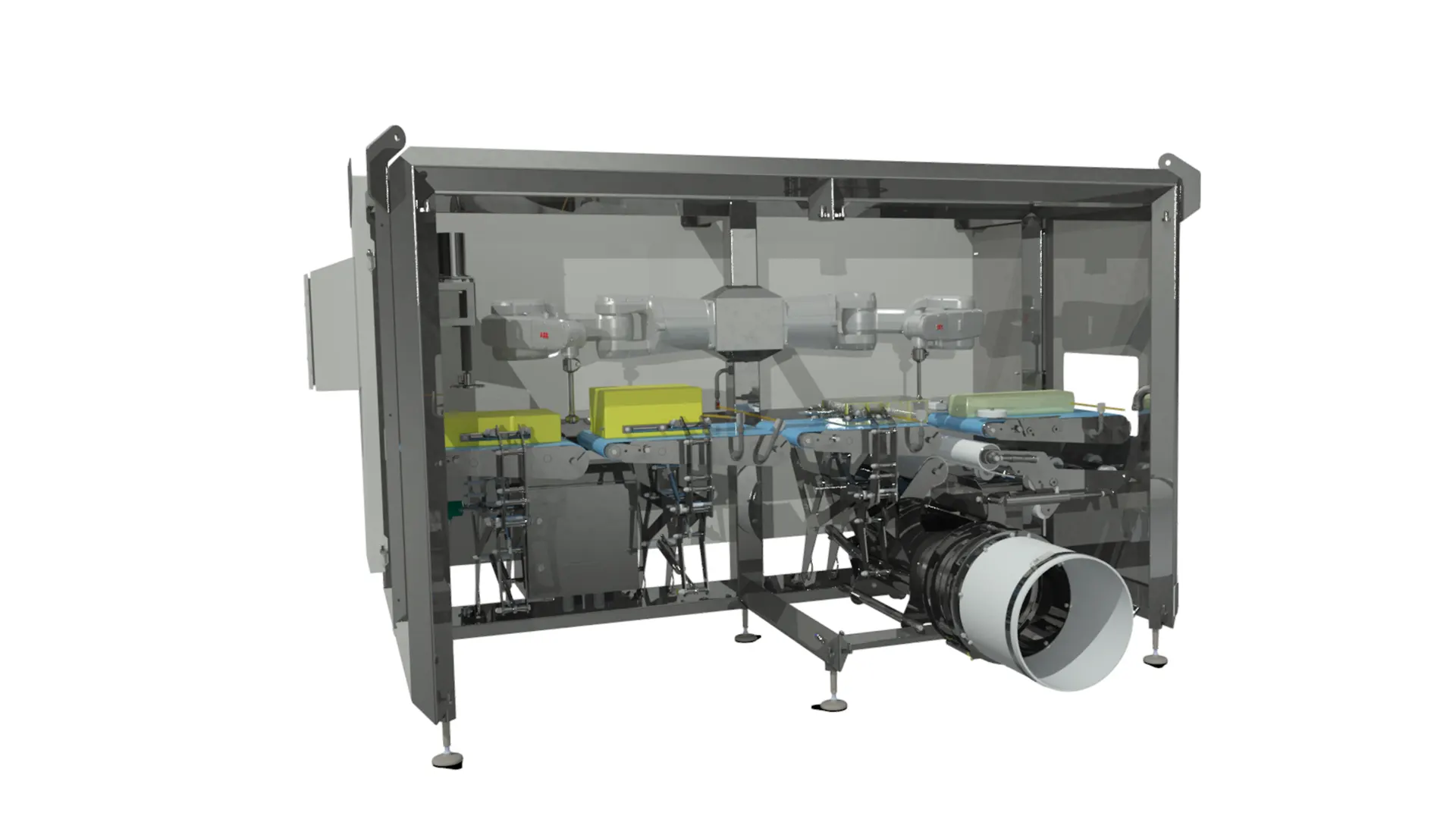

Automates the removal of vacuum bags from multiple cheese block shapes and sizes.

Also known as the De-Bagger Multi-Block, De-foiler or DBMB, the Robotic De-bagger is capable of managing virtually any block size or type on-the-fly, without operator input.

It safely and reliably removes the vacuum bag to present an undamaged, uncontaminated block to the processing line every time.

When combined with the Defect and Foreign Object Detection (DFOD) module, the system provides unprecedented confidence that the product entering the processing line is in perfect condition, free from defects and plastic bag residue.

Key benefits:

- Risk of product contamination is removed

- Reduced labour – allows staff to be re-deployed to higher value work

- Manual handling, knives and the associated risk of injury to staff is eliminated

- Waste plastic is managed efficiently

- A single machine will handle multiple cheese formats

Also known as the De-Bagger, Debagger, De-foiler, Defoiler, Multi Block, or DBMB.

Previously known as the H&C de-bagger, this technology was originally developed by Haden & Custance, which became part of MHM Automation in 2016.