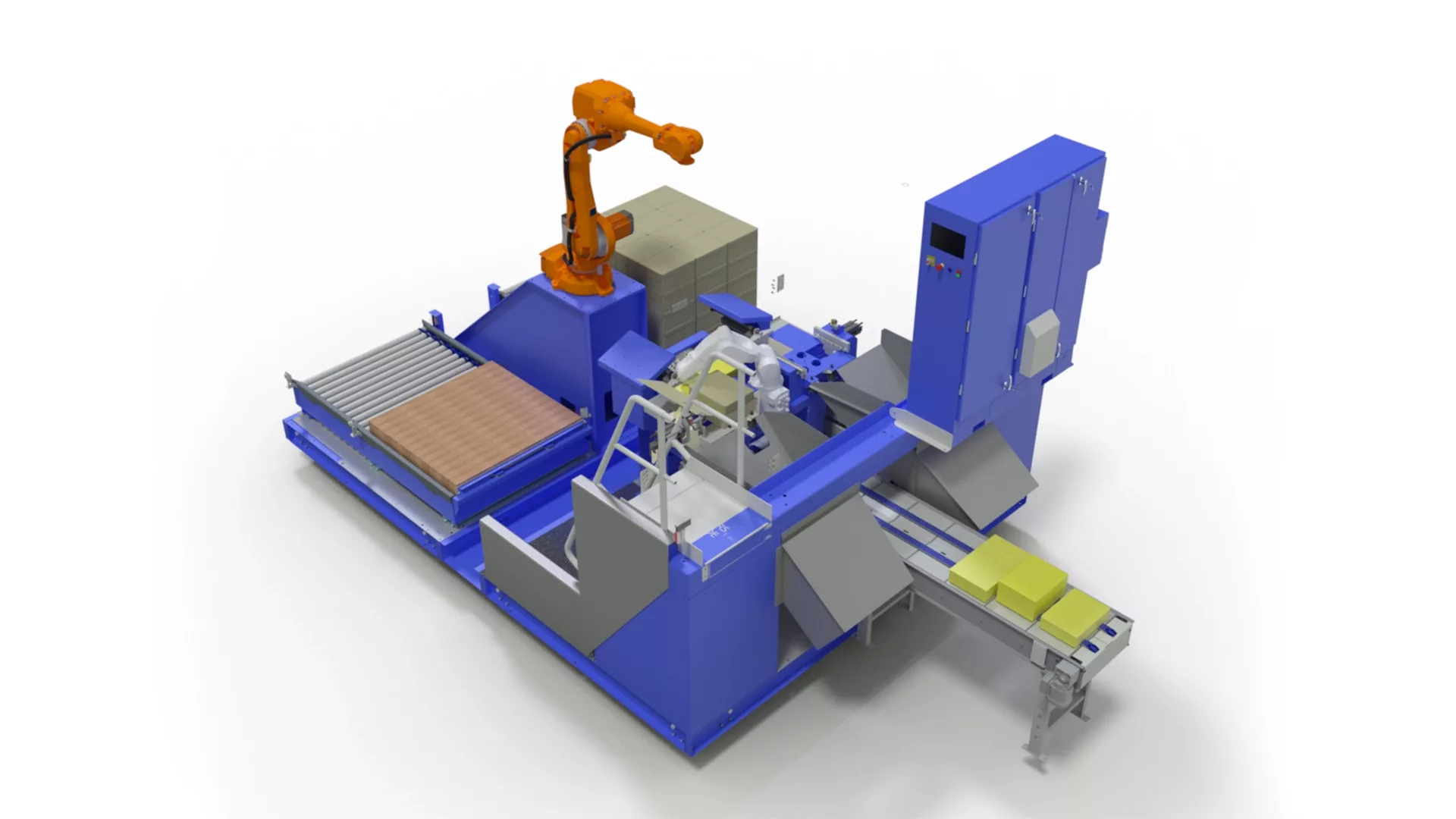

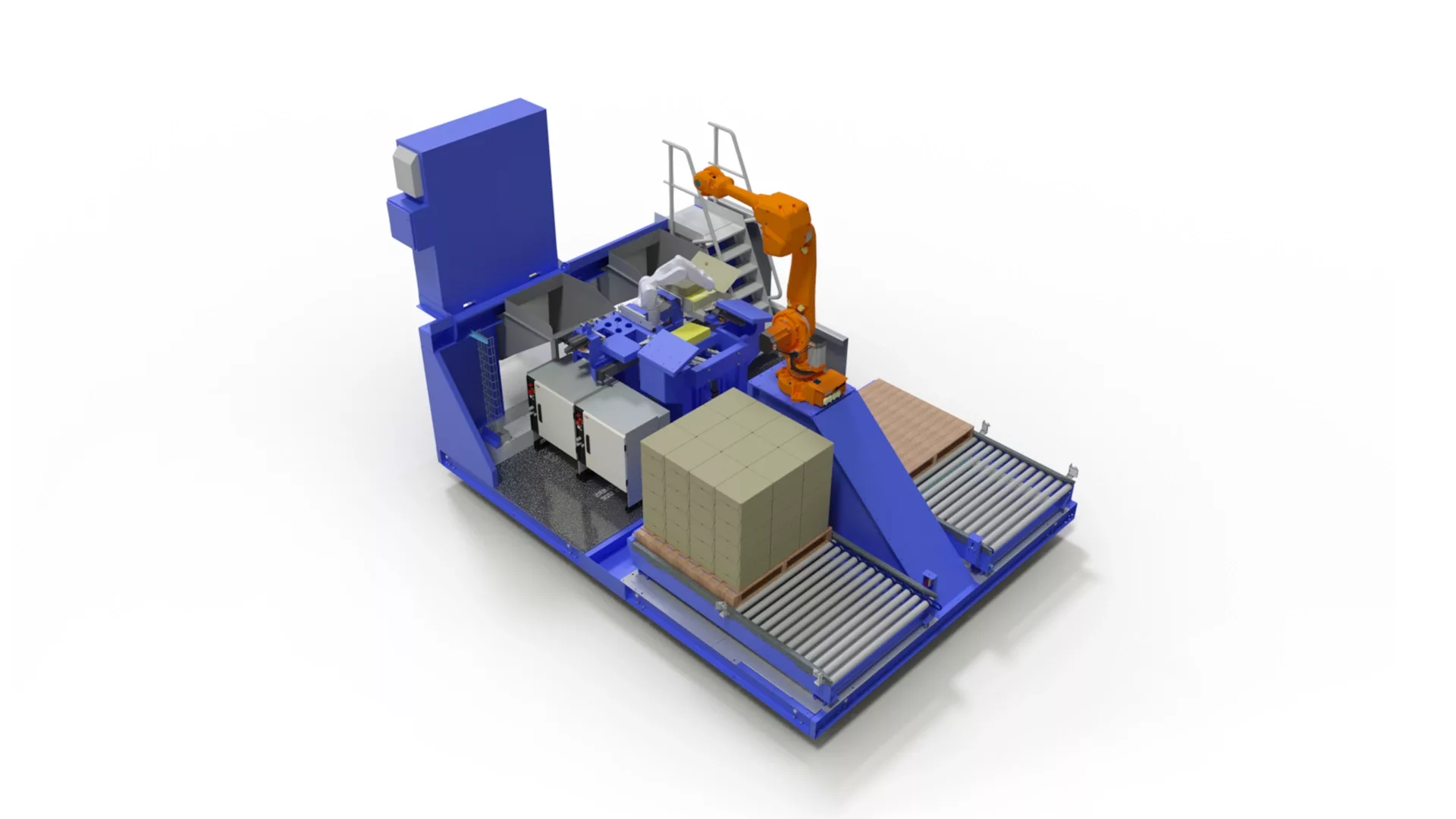

Robotic De-Boxing Cell (DDRP-MB)

De-palletise, de-box, re-palletise and process multiple blocks the efficient way with the Robotic De-Boxing Cell.

De-palletise, de-box, re-palletise and process multiple blocks the efficient way with the Robotic De-Boxing Cell.

Previously known as H&C Robotic De-Boxing Cell , these were originally developed by Haden & Custance (H&C), which is now part of MHM Automation.

While many other companies provide solutions to putting product into packaging, we are specialists in removing packaging from product ready for further processing.