De-Palletise, De-Carton, Re-Palletise (DDRP-40)

De-palletise, de-box and re-palletise 40lb / 20kg cheese blocks the efficient way.

De-palletise, de-box and re-palletise 40lb / 20kg cheese blocks the efficient way.

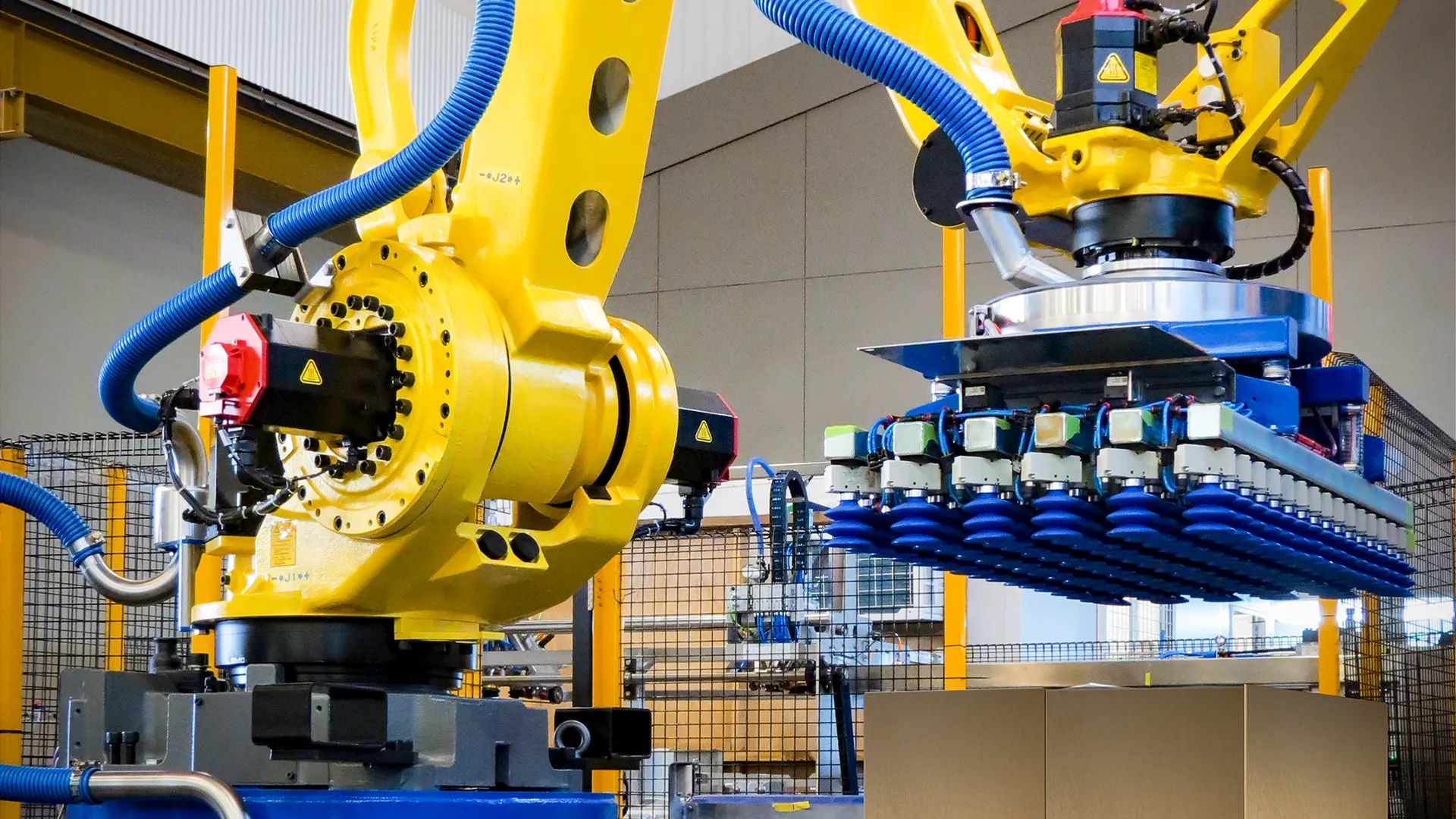

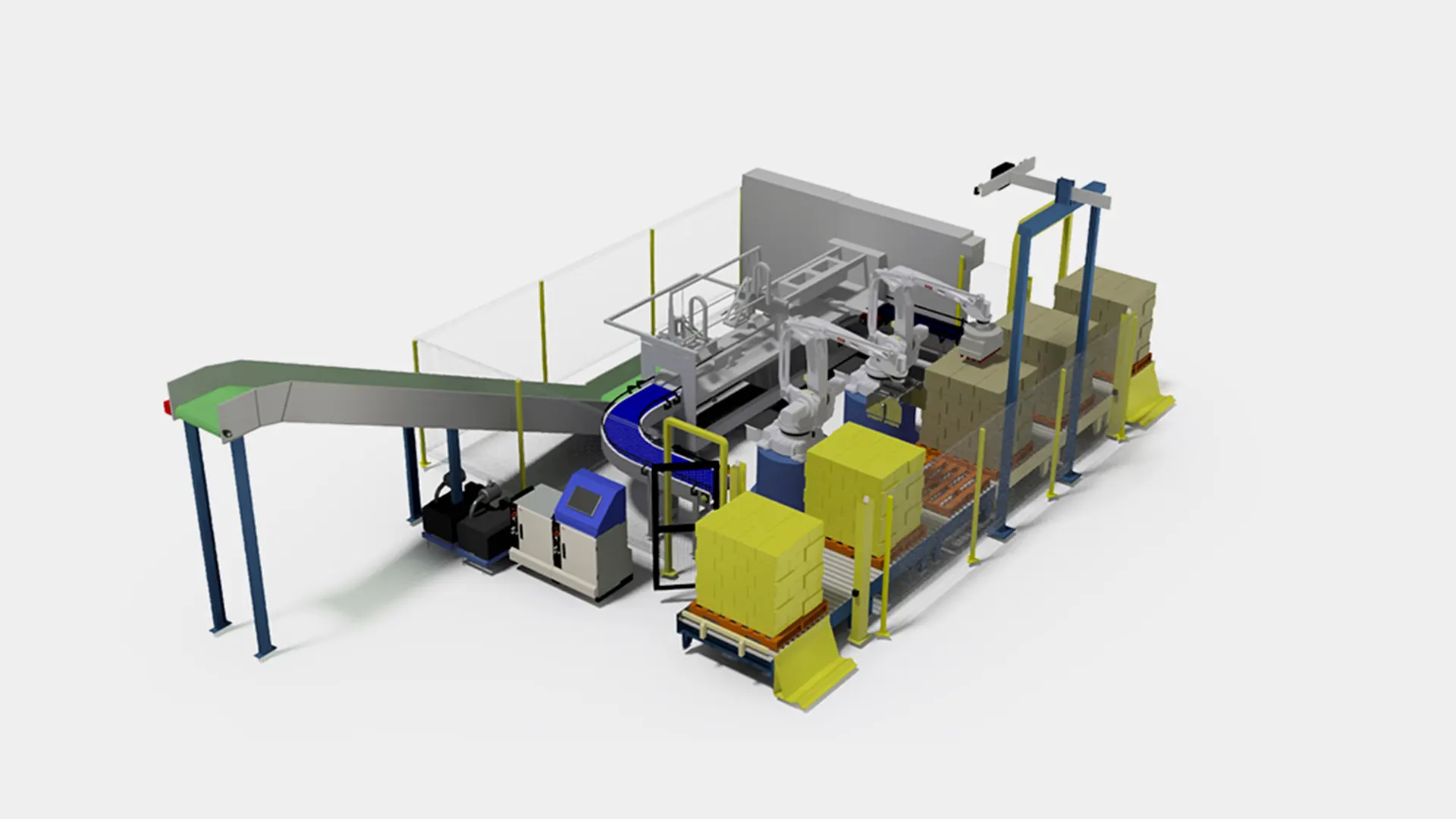

Also known as the DDRP-40, the De-palletise, De-carton, Re-palletise system removes 40lb boxes from a pallet, removes the cartons and re-palletises the bagged blocks again at a rate of up to 16 blocks per minute.

It features the unique 3 Dimensional De-palletising (3DD) vision system, which detects boxes of product in any configuration and enables optimal pick-up to deliver faster and more reliable de-palletising.

The DDRP-40 uses MHM’s superior cutting and carton removal technology to provide unparalleled reliability. It will safely remove the outer packaging, presenting an undamaged, wrapped block every time. With a proven track record in the industry, this is the best de-cartoning system available in the market today.